Pre-Painted Galvanized/Aluzinc Steel Coil,Red Color of Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

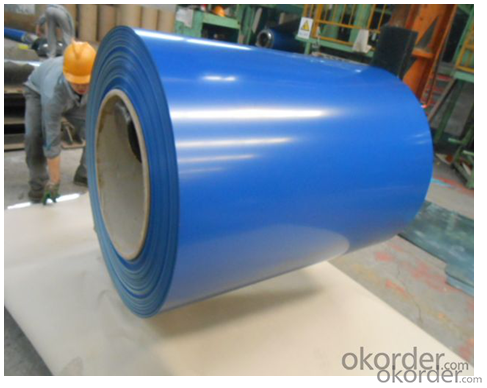

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q:Ok so i have a certain amount of money that I want to invest in either GE or US Steel. Tickers: ge, x. GE looks like a strong co, but less risk. Whereas US Steel looks risky, but high reward. :). i am willing to take risks. Any comments?

- i think you should invest in marlyn co. with protection against friends who act like hoes!!!!! charmin ultra less is more!!

- Q:How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc or another protective coating is applied to the surface of the steel. This coating acts as a barrier, preventing moisture from coming into direct contact with the steel and minimizing the risk of corrosion. Additionally, steel coils are often stored in dry, enclosed spaces or wrapped with moisture-resistant materials such as plastic or wax paper to further protect them from humidity.

- Q:Is steel easier to weld?Which is more brittle/less flexible?

- You should not attempt to do any traditional welding of steel to aluminum as they can form a hard and brittle inter metallic compound known as iron aluminide. You would have to employ a process that did not melt either species. Cladding could be an option but you are kind of limited to flat products that are sandwiched together. There is also explosive which does almost the same thing as cladding. Friction stir welding might be possible but I cant vouch for that. The temperature does get pretty hot, so I am not sure what would happen. But any of these suggestions would take specialized equipment not available to the average user. For weight, Al is 2.7 g/cc and Iron is about 7.8 so it is about 3 times heavier for the same volume. How strong either of them are greatly depends on specific alloys and heat treatment. I think some of the strongest aluminum alloys have a yield strength of about 50,000 psi which would relate to a relatively weak steel. For steel, there are alloys that can have yield strengths in the hundreds of thousands psi.

- Q:Measures to prevent cold rolling of packaged cold rolled steel coils? Who can give some professional opinions oh?

- Cold rolled steel coils are generally sprayed antirust oil, according to user requirements, light, medium, heavy oil 3 types. Nevertheless, if the oil is volatile or in a humid environment, the steel plate comes into contact with the water for a period of time, indicating that it is beginning to rust.

- Q:I worked REALLY HARD basically begged my dad to let me stretch my ear lobe piercings. He finally said yes, as long as I don't pass 2g. c: So, we went to Hot Topic to buy tapers, but I don't know if I should get Steel or Acrylic tapers. Which ones are better to start off with?

- Steel

- Q:Is there any other way of testing whether or not you have a 1944 Steel penny that won't damage the penny. The magnet test doesn't seem to work cause even when I try to get a 2007 penny to stick to the magnet...it won't. So is there some kind of magnet needed? Like power wise or anything like that, if not then I need to know what are other ways of testing the 1944 penny.

- 1944 Penny Steel

- Q:How are steel coils used in the production of shipping vessels?

- Steel coils are an essential component in the production of shipping vessels. These coils are typically made from high-strength steel, which makes them ideal for constructing the hulls and other structural components of the ships. In the shipbuilding process, the steel coils are first unrolled and cut into specific sizes and shapes according to the ship's design. These pre-cut pieces are then welded or bolted together to form the framework of the vessel. This framework provides the necessary strength and rigidity to withstand the harsh conditions of the sea. Steel coils are also used to manufacture the decks, bulkheads, and other interior components of the shipping vessels. These coils are molded and shaped into various sections that are then assembled and attached to the ship's structure. The use of steel coils in these areas ensures durability and resistance to corrosion, which is crucial for the longevity and safety of the vessel. Furthermore, steel coils are used in the production of ship propellers, rudders, and steering mechanisms. These components are crucial for controlling the direction and movement of the ship. The high-strength steel coils provide the necessary strength and reliability to ensure smooth and efficient navigation. Overall, steel coils play a vital role in the production of shipping vessels by providing strength, durability, and resistance to corrosion. They are used in various parts of the ship's construction, including the hull, decks, bulkheads, and interior components. Without steel coils, the production of shipping vessels would be challenging, and the resulting ships would lack the necessary structural integrity to navigate the seas safely and efficiently.

- Q:who, when and where was dual phase steel invented?

- Dual Phase steels refers to a distinct group of alloys which are used for automotive bodies. These were developed to give improved deep drawing (for shaping) and strength while on the road. Most of the work was started at the same time in the 1970s as a response to the oil crisis (history repeats!) with SSAB in Europe, US Steel and British Steel leading the way. There are many variants of the dual phase alloys prefered by each of the auto manufacturers. The work on these steels led the way for TRIP (transformation induced plasticity) steels, rephosphorised steels and HSLA (high strength low alloy) steels. There is a distinction between these steels and duplex steels which typically refer to austenitic/ferrtic stainless steels. Also be aware that everyday low carbon steels with 0.1%-0.6% carbon will have a ferritic/pearlitic structure but are not considered to be dual phase So to summarise: Who - major steel companies worldwide When - from about 1973 onwards (up to around 1977 when the developments went in other directions) Where - Europe, USA and Japan (but I'm not sure who it was in Japan doing the work)

- Q:How do steel coil manufacturers manage inventory?

- Steel coil manufacturers employ a variety of strategies and techniques to effectively manage their inventory, optimize production, minimize costs, and meet customer demands. The following are some commonly used practices: 1. Accurate demand forecasting: Steel coil manufacturers analyze market trends, historical sales data, and customer orders to accurately forecast future demand. This enables them to determine the necessary inventory levels and plan production accordingly. 2. Just-in-time (JIT) inventory: Many steel coil manufacturers adopt the JIT inventory system, which involves maintaining minimal inventory levels by receiving raw materials shortly before production and delivering finished goods immediately after. This approach reduces carrying costs and mitigates the risk of excess inventory. 3. Collaborating with suppliers: Effective inventory management relies on close collaboration with suppliers. Steel coil manufacturers work closely with their suppliers to ensure timely delivery of raw materials, monitor quality, and maintain a consistent supply. Regular communication and sharing of production forecasts help suppliers plan their inventory accordingly. 4. Safety stock: Steel coil manufacturers maintain a certain level of safety stock to account for unpredictable fluctuations in demand, disruptions in the supply chain, or delays in raw material deliveries. This acts as a buffer to prevent stockouts and maintain customer satisfaction. 5. Implementing inventory control systems: Steel coil manufacturers utilize modern inventory control systems, such as Enterprise Resource Planning (ERP) software, to track inventory levels, monitor stock movements, and automate various inventory management processes. These systems provide real-time data and analytics, facilitating better decision-making and improving inventory accuracy. 6. Streamlining production planning: Steel coil manufacturers optimize production planning to minimize inventory holding costs. They schedule production based on demand forecasts, prioritize orders, and strive for efficient production runs to reduce setup times and material waste. 7. Regular inventory analysis: Steel coil manufacturers regularly analyze their inventory data to identify slow-moving items, obsolete stock, or excess inventory. By identifying such issues, they can take corrective actions such as offering discounts, initiating sales promotions, or adjusting production schedules to prevent inventory buildup. In conclusion, effective inventory management is crucial for steel coil manufacturers to maintain a lean and efficient operation while meeting customer demands. By utilizing these strategies, manufacturers can strike a balance between supply and demand, reduce costs, and enhance customer satisfaction.

- Q:What is the role of steel coils in the production of conveyors?

- The role of steel coils in the production of conveyors is to provide structural support and strength to the conveyor system. Steel coils are used to create the framework and components of the conveyor, ensuring durability and reliability in moving heavy loads. They are the backbone of the conveyor, allowing it to handle various materials and withstand the stresses of continuous operation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil,Red Color of Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords