High-Quality PPR Fitting End Plastic Tubes with Safety Guarantee from Top Chinese Factory

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 45000 pc

- Supply Capability:

- 1800000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

Advantages of PPR pipe

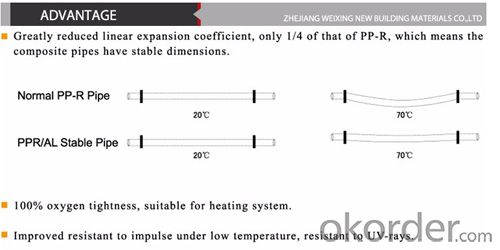

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

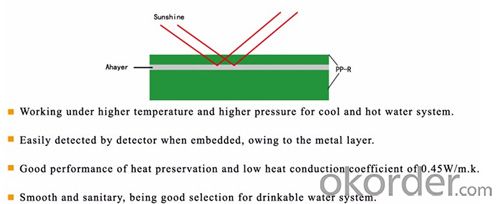

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

Features of PPR

PPR pipe also known as three polypropylene pipe using a random copolymer polypropylene by extrusion become pipe, injection molded into the tube. PPR pipe is the development and application of new plastic pipe products in the early 1990s of the European. The late 1980s, PPR is the use of a gas phase copolymerization process so that about 5% PE in the molecular chain of PP random homogeneous polymerization (random copolymer) and a new generation of pipe materials. It has a good impact resistance and long-term creep performance.

PPR pipes have the features of light weight, corrosion resistance, no scaling, long life, but also have the following characteristics:

1. Non-toxic health: raw material molecule only carbon and hydrogen elements, not only for hot and cold water pipes, can be used to clean drinking water systems;

2. Energy-saving insulation: pipe thermal conductivity 0.21W / MK, steel is only 1/200;

3. Better heat resistance: PPR pipe Vicat softening point of 131.5 ℃, the maximum working temperature up to 95 ℃, can meet the water supply and drainage requirements specification hot water system;

4. Long life: PPR operating temperature 70 ℃, working pressure (PN) conditions under 1.0Mpa life of up to 50 years at room temperature (20 ℃) the service life of up to 100 years;

5. Install reliable connection: PPR pipe has good weld ability, pipe fittings can be used hot-melt and fused connections, easy installation, reliable joints, the strength of joints is greater than the strength of the pipe itself;

6. Recyclable materials: does not affect product quality.

How to choose a safe and economical PPR pipe?

1. Note that the overall pipeline utilization factor C (that is, the safety factor) is determined. General case, and long-term continuous use temperature is less than 70 ℃, optional C is equal to 1.25. On important occasions and long-term continuous use temperature of greater than or equal to 70 ℃, and is likely to run at a higher temperature for a long time, an optional C = 1.5;

2. For cold water (≤40 ℃) system, the choice of PN1.0 ~ 1.6Mpa pipe, fittings, hot water system for the selection of greater than or equal to 2.0Mpa pipe, tube.

- Q: What is the transition metal pipe between the plastic water supply pipe and the water heater?

- The transition piece is a combination of plastic and metal, and the two materials are processed by injection molding process, and the anti leakage sealing is realized through the internal structure without adding other adhesive materials.

- Q: i want to buy it

- It depends on the size and the brand. They can cost anywhere from 4-25 dollars.

- Q: Im looking for plastic tubes like pvc, but clear. about 3ft in length. where can i find it?

- I would check with a store like Home Depot, or Lowes, or other hardware stores. you might want to check Wall-Mart too.

- Q: Are plastic tubes suitable for high-pressure applications?

- No, plastic tubes are generally not suitable for high-pressure applications as they may deform or burst under high pressure, posing a safety risk.

- Q: What's the full name of "PPC plastic pipe"?

- Poly propylene carbonate, English propylene full name Poly carbonate, abbreviation PPC, also known as poly methyl ethylene carbonate, which is based on carbon dioxide and propylene oxide as an environment-friendly biodegradable plastic raw materials.

- Q: Are plastic tubes resistant to freezing temperatures?

- Yes, plastic tubes are generally resistant to freezing temperatures.

- Q: Plastic pipe joint leakage of water can be done with glue

- 1, you can use monengjiao, special glue PVC pipe to repair, but it is best to use lateral waterproof fabric reinforcement;2, tap water pressure is relatively large, not recommended for simple repair, you can contact the professionals will be part of the leakage of water, the use of hot melt equipment and other replacement of new pipes.

- Q: Can plastic tubes be used for insulation in construction?

- Yes, plastic tubes can be used for insulation in construction. They are commonly used to insulate pipes and electrical wires to protect them from heat loss or gain and to prevent condensation. Plastic tubes provide a cost-effective and durable solution for insulation in various construction applications.

- Q: I'm doing a science fair project and I am in great need of test tubes.-Thanks! =]

- 1. Get 24 thongs and randomly put them in people's carts whenthey aren't looking. 2. Set all the alarm clocks in Housewares to go off at 5-minute intervals 3. Make a trail of tomato juice on the floor leading to the restrooms. 4. Walk up to an employee and tell him/her in an official tone,'Code 3' in housewares..... and see what happens. 5. Go the Service Desk and ask to put a bag of MM's on lay away. 6. Move a 'CAUTION - WET FLOOR' sign to a carpeted area. 7. Set up a tent in the camping department and tell other shoppers you'll invite them in if they'll bring pillows from the bedding department. 8. When a clerk asks if they can help you, begin to cry and ask Why can't you people just leave me alone? 9 Look right into the security camera; use it as a mirror, and pick your nose. 10. While handling guns in the hunting department, ask the clerk if he knows where the anti- depressants are. 11. Dart around the store suspiciously loudly humming the Mission Impossible theme. 12. Go into a fitting room and shut the door and wait a while and, then, yell, very loudly, There is no toilet paper in here! 13. When an announcement comes over the loud speaker, assume the fetal position and scream NO! NO! It's those voices again!!!! ( And; last, but not % ) 14. Hide in a clothing rack and when people browse through, say PICK ME! PICK ME!

- Q: Are plastic tubes resistant to weathering?

- Yes, plastic tubes are generally resistant to weathering.

Send your message to us

High-Quality PPR Fitting End Plastic Tubes with Safety Guarantee from Top Chinese Factory

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 45000 pc

- Supply Capability:

- 1800000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords