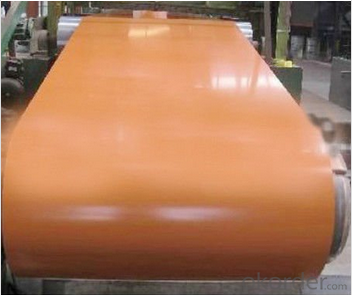

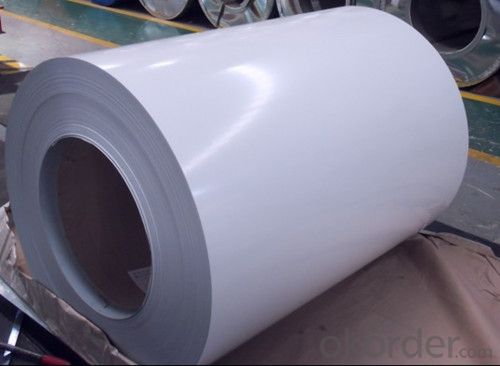

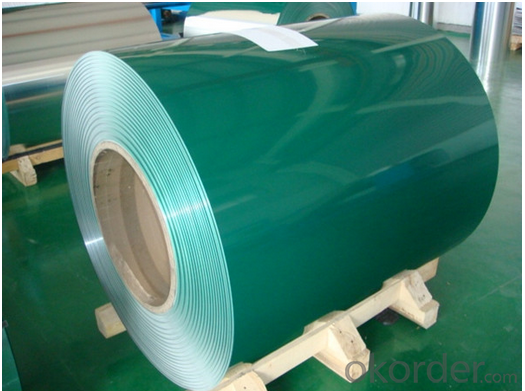

PPGI Metal Building Materials /Pre-painted Hot Dipped Galvanized Steel Coil/Aluminized

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.PPGI Metal Building Materials Features:

. A strong anti-corrosion properties, good corrosion resistance. The use of hot dipped galvanized steel substrates for the Color Painted steel coil, with the exception of zinc have anti-corrosion layer, a layer of coatings have seized coverage and protection, allowing effective anti-rust products, galvanized coil about life than double.

. A good cold-formed molding processing, users can directly processed into finished products. Substituting wood to steel, easy to transport, and efficient construction, energy conservation.

2.Applications of PPGI Metal Building Materials

* Used as roof panel, wall panel in steel structure in warehouse,

factories exhibition hall container houses, cold storage

*It is also mainly used in light industry, automobile, construction,

animal husbandry, fishery and commerce, etc,

3.Product information:

| PRODUCT | PPGI Metal Building Materials |

| STANDARD | GB/T-12754: 2006, JIS330, ASTM A653, JIS G330, GB/T2518, ASTM A792, JIS G3321, JIS G3317 |

| BASE METAL | Hot dipped Galvanized steel sheet/coil, Hot dipped Galvalume steel sheet/coil |

| EQUIPMENT | Double coating double baking; three coating three painting |

| SUPPLY CAPACITY | 500,000 Tons per Year |

| SIZE | Thickness: 0.3mm-1.0 mm,thickness tolerance: +/- 0.02mm Width : 700mm—1250mm |

| ZINC COATING | 30g/m2-150g/m2 |

| PAINT THICKNESS | Top Side: 10-25 microns; Back Side: 4-8 microns |

| COIL WGT | Normally 5 Tons per Coil, aslo as required by customer |

| COIL ID | 508mm/610mm |

| SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

4.PPGI Metal Building Materials image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the different types of steel coil cutting methods?

- There are several different types of steel coil cutting methods, including shearing, slitting, and laser cutting. Shearing involves using a straight blade to cut through the coil, while slitting involves using circular blades to make multiple cuts. Laser cutting is a more precise method that uses a laser beam to cut through the coil. Each method has its advantages and is chosen based on the specific requirements of the project.

- Q: What are the different types of edge conditions in steel coils?

- Some of the different types of edge conditions in steel coils include mill edge, slit edge, and sheared edge. Mill edge refers to the original edge produced during the steel manufacturing process. Slit edge is created when the steel coil is cut into narrower strips. Sheared edge is formed when the coil is trimmed using a cutting tool. These various edge conditions have different characteristics and can impact the usability and appearance of the steel coils.

- Q: How are steel coils used in the production of power transmission towers?

- Steel coils are used in the production of power transmission towers because they provide the necessary strength and structural integrity required to support the transmission lines. The coils are formed into various sections and welded together to create the tower's framework, ensuring it can withstand the weight of the cables and withstand external forces such as wind and seismic activity.

- Q: how is stainless steel made? what are the things used in making it?

- There are different recipes, and different types of steel are made for different purposes. They all share high temperatures, which allows extra carbon to bind with the iron. This is the main thing that makes steel stainless, or rustproof. Other metals such as chromium, molybdenum, magnesium etc. are often added to increase tensile (twisting) strength, flexibility, etc.

- Q: How are steel coils used in the manufacturing of body panels?

- Steel coils are used in the manufacturing of body panels as they are rolled into flat sheets and then cut and shaped to form the desired body panel design. These coils provide the necessary strength and durability required for automotive body panels, ensuring that they can withstand the rigors of everyday use and provide structural integrity to the vehicle.

- Q: How are steel coils used in the production of electrical devices?

- The production of electrical devices heavily relies on steel coils. These coils, typically made from high-quality steel, are precisely wound into a circular shape. They have a crucial function in various electrical devices, including transformers, motors, generators, and inductors. Transformers, for instance, heavily rely on steel coils. These devices are essential for adjusting voltage levels in electrical circuits. They consist of two separate coils, the primary and secondary coils, which are wound around a magnetic core. The steel coil plays a vital role in providing stability and support to the windings, ensuring proper alignment and preventing any deformation. Moreover, the high magnetic permeability of steel helps enhance the efficiency of energy transfer between the coils. In motors and generators, steel coils are utilized to create magnetic fields that either generate mechanical energy or convert it into electrical energy. These coils are wound around an armature or rotor, which rotates within a magnetic field created by a stator. As the current flows through the coils, a magnetic field is produced, resulting in the rotation of the armature or the generation of electrical power. Steel coils are also used in inductors, another type of electrical device. Inductors consist of a coil of wire wound around a core material, often made of steel. Steel coils in inductors help increase the inductance, which measures the device's ability to store energy in a magnetic field. By storing energy in this manner, inductors can regulate currents, filter out noise, and provide stability to electrical circuits. All in all, steel coils are indispensable in the production of electrical devices. They provide stability, support, and enhance the necessary magnetic properties for efficient functioning. Without steel coils, the performance and reliability of electrical devices like transformers, motors, generators, and inductors would be greatly compromised.

- Q: for my engineering project I have been asked to design a method of suspending a TV of weight 14Kg from a gantry, the TV must be 5m below the gantry. My team have decided to use as a suspension method a steel cylinder of outer diameter of 10cm and an inner diameter of 8, however we now need to work out both the max stress and strain and the actual stress and strain. and help would be useful

- In most engineering calculations we have to make some assumptions about ideal behavior of a material otherwise we would not be able to simplify our equations to manageable sizes. Your steel cylinder (which I'll call a pipe) is made of a certain type of steel. That steel type has property tolerances listed in a steel manual to help you know about your steel before you begin. You'll need to know the cross-sectional area of the pipe and the weight of the TV to determine an average stress on the pipe. Obviously the weight of the TV is the force it generates. The force is its mass x gravitational acceleration. Since we typically think of steel as an elastic material, we think of it stretching like a rubber band or a spring. You pull it down with a TV and it deflects a certain amount, and will return to its original length when the TV is removed. It is typical to assume that all steel, regardless of its strength, has the same value for this elastic property. It is commonly referred to as the elastic modulus. This value will help you determine what type of strain occurs under what type of stress. So, once you have the stress, you can get the strain by using the elastic modulus. Once you have the strain you can determine the deflection based on the pipe length. Having the steel properties will help you determine how close your TV comes to stressing the pipe to its yield stress. If you reach a yield stress, your steel will deflect, but when you take the TV off it will not return to its original shape. I hope I've helped outline some of the things you'll need to do for the project, I tried not to give away specifics so that you can actually engage your brain around the project. Enjoy, learn a lot, and realize that this skill could easily turn into a career where you are designing projects that when done correctly save people's lives every day of the year.

- Q: How are steel coils used in the manufacturing of solar panels?

- Steel coils are commonly used in the manufacturing of solar panels to provide structural support and stability. These coils are typically used to create the framework of the solar panel, ensuring that it remains rigid and durable. Additionally, steel coils can be used to create the mounting structures that hold the solar panels in place, allowing for easy installation and maintenance.

- Q: How are steel coils used in the manufacturing of airbags?

- Steel coils are used in the manufacturing of airbags to provide structural support and stability. These coils are typically incorporated into the airbag module, helping to maintain its shape and ensure proper deployment in the event of a collision.

- Q: I'm ordering a Pair of tongs(a tool used to dig quahogs in bays that scrapes the bottom constantly) and what type of metal would be the best to fabricate it, steel or stainless steel?

- Whilst doing a welding course a few years ago the teacher said stainless steel was not its proper name,it is called Heat and Corossion resistant steel,it come in different grades related to its corossion resistance,priced accordingly.Must be welded properly without introduction of carbon to the weld (carbon pickup) or the weld might not be there next time you look dependant on environment.Generally harder to form than mild steel (low carbon steel) so it will tend to be stronger than lcs for the same cross section.steve

Send your message to us

PPGI Metal Building Materials /Pre-painted Hot Dipped Galvanized Steel Coil/Aluminized

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords