All Categories

- - Steel Wire Rod

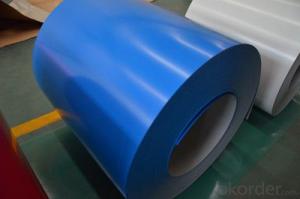

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do variations in coil temperature impact the quality of laser-cut components used in precision engineering and metalworking?

Variations in coil temperature can significantly impact the quality of laser-cut components used in precision engineering and metalworking. Laser cutting relies on precise heat application to cut through material, and any fluctuations in the coil temperature can lead to inconsistent cutting results. Higher coil temperatures can cause the material to heat up excessively, resulting in distortion, warping, and rough edges. On the other hand, lower coil temperatures may lead to incomplete or inaccurate cuts. Therefore, maintaining a consistent and controlled coil temperature is crucial to ensure the production of high-quality, precise laser-cut components in precision engineering and metalworking.

How are steel coils tested for their weldability in the manufacturing of pipelines?

Steel coils are tested for their weldability in the manufacturing of pipelines through various methods, including destructive and non-destructive testing techniques. Destructive testing involves taking samples from the steel coils and subjecting them to welding processes, such as the V-groove test, to assess their weld quality and integrity. Non-destructive testing methods, such as ultrasonic testing and radiographic inspection, are also employed to detect any structural defects or imperfections in the steel coils that could affect their weldability and overall quality. These rigorous testing procedures ensure that only steel coils with excellent weldability characteristics are used in the manufacturing of pipelines.

How are steel coils prepared for wire drawing?

Steel coils are prepared for wire drawing by first cleaning them to remove any dirt or rust. They are then annealed to soften the steel and make it more malleable. After annealing, the coils are pickled to remove any scale or impurities from the surface. Finally, the coils are coated with a lubricant to reduce friction during the wire drawing process.

Wholesale Steel Coils from supplier in Uruguay

With our expertise in supplying Steel Coils, we can help you find the right products that meet your specific requirements. Our comprehensive range includes various types of Steel Coils, such as hot-rolled coils, cold-rolled coils, galvanized coils, and stainless steel coils.

We understand the importance of timely and accurate quotations, which is why our dedicated sales team will provide you with competitive prices and detailed information about our products. Our technical support team is also available to assist you with any questions or concerns you may have regarding the application and installation of Steel Coils.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and manufacturers, ensuring that we can offer a wide range of options for your Steel Coils needs. This allows us to provide convenient one-stop procurement solutions, saving you time and effort in sourcing different products from multiple suppliers.

Our extensive market experience in Uruguay gives us a deep understanding of the local industry trends and regulations. This enables us to provide valuable insights and expertise to help you make informed decisions for your projects. Whether you are in construction, manufacturing, or any other industry that requires Steel Coils, we can assist you in finding the best solutions that meet your specific needs and budget.

At our company, we prioritize customer satisfaction, and we strive to build long-term relationships with our clients. We are committed to providing high-quality products, reliable services, and excellent customer support. Contact us today to discuss your Steel Coils requirements and let us help you find the best solutions for your business in Uruguay.

We understand the importance of timely and accurate quotations, which is why our dedicated sales team will provide you with competitive prices and detailed information about our products. Our technical support team is also available to assist you with any questions or concerns you may have regarding the application and installation of Steel Coils.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and manufacturers, ensuring that we can offer a wide range of options for your Steel Coils needs. This allows us to provide convenient one-stop procurement solutions, saving you time and effort in sourcing different products from multiple suppliers.

Our extensive market experience in Uruguay gives us a deep understanding of the local industry trends and regulations. This enables us to provide valuable insights and expertise to help you make informed decisions for your projects. Whether you are in construction, manufacturing, or any other industry that requires Steel Coils, we can assist you in finding the best solutions that meet your specific needs and budget.

At our company, we prioritize customer satisfaction, and we strive to build long-term relationships with our clients. We are committed to providing high-quality products, reliable services, and excellent customer support. Contact us today to discuss your Steel Coils requirements and let us help you find the best solutions for your business in Uruguay.