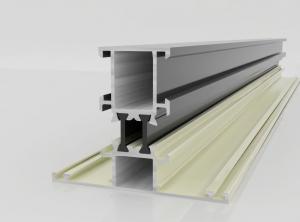

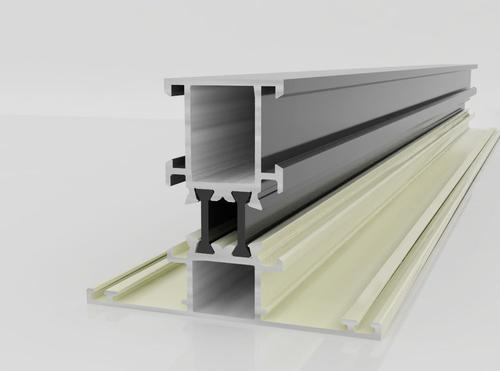

Customized Colorful Powder Coating Aluminum Door Profile AA6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Powder Coating Aluminum door profile of - AA6060

1) Material : 6063 6061 6060 and different aluminium alloy

2) Alloy Temper: T4 T5 T6 or other special status as per customer's needing.

3) Optional Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrophoretic sliver, electrophoretic champagne, electrophoretic golden,

electrophoretic titanium, machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4) Annual capacity : 120000TON

5) Quality : China Nation Standard GB/T 5237 2004 (advanced class)

6) Application: can be widely used for aluminium window, door, curtain wall, hand railing ,

normal aluminium profiles, decoration and industrial aluminium profiles.

7) Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

- Q: Can aluminum profiles be used in the construction of amusement park rides?

- Indeed, amusement park rides can be constructed using aluminum profiles. Aluminum is a favored material for building different parts of amusement park rides because of its lightweight nature and durability. The profiles can be effortlessly molded and joined together to form intricate structures like roller coaster tracks, supports, and frames for other rides. Moreover, aluminum's resistance to corrosion makes it suitable for outdoor settings where the rides are subjected to weather conditions. Furthermore, aluminum is an environmentally friendly option for amusement park ride construction as it can be recycled, showcasing its sustainability. In conclusion, aluminum profiles offer a flexible and dependable choice for creating secure and thrilling amusement park rides.

- Q: What precautions should be taken while handling aluminum profiles to ensure safety?

- <p>When working with aluminum profiles, it's important to take several safety measures. Always wear appropriate personal protective equipment (PPE), including safety glasses to protect your eyes from flying debris, gloves to protect your hands, and a dust mask to prevent inhalation of dust particles. Ensure that the work area is well-ventilated to avoid inhaling aluminum dust. Use proper tools for cutting and shaping aluminum profiles to minimize the risk of injury. Keep the work area clean and free from clutter to prevent tripping hazards. Be cautious when handling sharp edges and ends of cut aluminum profiles. Lastly, be aware of the weight of the aluminum profiles to avoid back injuries when lifting.</p>

- Q: What are the advantages of using aluminum profiles in the telecommunications infrastructure?

- Using aluminum profiles in the telecommunications infrastructure offers several advantages: 1. Lightweight: Aluminum profiles are much lighter than traditional materials like steel, making them easier to transport and install. This reduces labor costs and deployment time. 2. Resistant to corrosion: Aluminum has excellent resistance to corrosion, making it ideal for outdoor infrastructure exposed to harsh environmental conditions. It can withstand high humidity and exposure to chemicals. 3. High strength-to-weight ratio: Despite being lightweight, aluminum profiles have a high strength-to-weight ratio. This means they can support heavy equipment and structures while still being relatively light. They are perfect for applications such as antenna mounts and support structures. 4. Easy customization: Aluminum profiles can be easily customized to meet specific design requirements. They can be cut, drilled, or shaped to fit unique specifications, allowing for flexibility in design and installation. 5. Cost-effective: Aluminum profiles are generally more cost-effective compared to materials like steel or fiberglass. They require minimal maintenance, have a long lifespan, and can be recycled, reducing overall costs over the infrastructure's life cycle. 6. Electrical conductivity: Aluminum is an excellent conductor of electricity, making it suitable for telecommunications infrastructure where electrical conductivity is important. 7. Aesthetically pleasing: Aluminum profiles have a sleek and modern appearance, enhancing the overall aesthetics of the telecommunications infrastructure. This is particularly important in urban or residential areas where visual appeal is considered. Overall, the use of aluminum profiles in telecommunications infrastructure offers benefits such as lightweight design, corrosion resistance, high strength-to-weight ratio, customization options, cost-effectiveness, electrical conductivity, and aesthetic appeal. These advantages make aluminum profiles the preferred choice for various components within the telecommunications industry.

- Q: What are the advantages of using aluminum profiles in window and door frames?

- There are several advantages of using aluminum profiles in window and door frames. Firstly, aluminum is a lightweight material, making it easier to handle and install. Additionally, it is highly durable and resistant to corrosion, ensuring long-lasting performance. Aluminum profiles also offer excellent thermal insulation, helping to reduce energy consumption and maintain comfortable indoor temperatures. Moreover, aluminum is highly versatile, allowing for various design options and customization. Finally, aluminum is an environmentally friendly choice, as it is recyclable and has a low carbon footprint.

- Q: What are the different types of aluminum alloys used for profiles?

- There are several different types of aluminum alloys used for profiles, including 6061, 6063, and 7075. These alloys offer varying levels of strength, corrosion resistance, and machinability, making them suitable for different applications. 6061 is a commonly used alloy for general structural purposes, while 6063 is often used for architectural and decorative applications due to its excellent finishing properties. On the other hand, 7075 is a high-strength alloy primarily used in aerospace and high-performance applications.

- Q: What is aluminum profile?

- 4) non ferromagnetic; aluminum is non ferromagnetic, which is an important feature of the electrical and electronic industries. Aluminum can not be spontaneous combustion, which is involved in loading and unloading or exposure to flammable and explosive materials is important. 5) machinability; the machinability of aluminum profiles is excellent. In a variety of wrought aluminum and cast aluminum alloys, and in the various states after which these alloys are produced, the machining characteristics vary considerably, which requires special machine tools or techniques. 6) formability; specific tensile strength, yield strength, ductility, and corresponding work hardening rate govern the amount of allowable deformation. 7) recovery; aluminum is highly recycled; the characteristics of recycled aluminium are almost the same as those of primary aluminum. According to the use of classification: 1. construction aluminum profiles (divided into doors and windows and curtain wall two). 2. radiator aluminum profiles. 3. general industrial aluminum: mainly used in the manufacture of industrial production, such as automation equipment, covering the skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, shelves and so on, the electrical machinery industry and clean room with. 4, rail vehicle structure aluminum alloy profile: mainly used for rail vehicle body manufacturing. 5, Mount Aluminum profiles, made of aluminum alloy frame, mounted a variety of exhibitions and decorative paintings.

- Q: This question asks for a list of different types of fasteners that are typically used in conjunction with aluminum extrusions.

- <p>Common types of fasteners used with aluminum extrusions include: 1. T-nuts and T-bolts, which provide a secure way to mount components to the extrusion. 2. Clamps and brackets, which can be used to hold items in place without drilling. 3. Corner brackets, which are used to connect two extrusions at right angles. 4. End caps, which protect the ends of the extrusion and can also serve as a mounting point. 5. Dowel pins, which are used to align and secure extrusions together. 6. Spacers, which maintain a consistent distance between extrusions. 7. Adhesives, which can be used for bonding parts to the extrusion. 8. Rivets, which provide a permanent connection between extrusions and other materials. These fasteners are chosen based on the specific application, load requirements, and design considerations.</p>

- Q: What is the difference between the two, or how to distinguish it from the outdoor curtain wall?

- Aluminum material refers to the blank material, which is used directly without artificial aging

- Q: This question asks for guidance on selecting suitable aluminum profiles for a construction project.

- <p>To choose the right aluminum profiles for your building project, consider the following: 1. Load-bearing capacity: Select profiles that can withstand the weight and stress of your structure. 2. Application: Choose profiles suitable for the specific application, such as window frames, curtain walls, or support beams. 3. Aesthetics: Opt for profiles that match your project's design and architectural style. 4. Durability: Look for high-quality aluminum with good corrosion resistance and weather resistance. 5. Cost: Compare prices and choose profiles that offer the best value for money. 6. Supplier reputation: Work with reputable suppliers known for quality products and reliable service. Consult with engineers or architects to ensure you select the most appropriate profiles for your project's needs.</p>

- Q: Are aluminum profiles suitable for use in the construction of high-rise buildings?

- <p>Yes, aluminum profiles can be used in high-rise buildings. They are known for their high strength-to-weight ratio, which makes them ideal for structural applications where weight is a concern. Aluminum profiles are also resistant to corrosion and can withstand harsh weather conditions, making them a popular choice for exterior applications. Additionally, their recyclability and sustainability make them an environmentally friendly option. However, it's important to ensure that the aluminum profiles meet the specific load-bearing requirements and safety standards for high-rise construction.</p>

Send your message to us

Customized Colorful Powder Coating Aluminum Door Profile AA6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords