Customized Color Coated Aluminum Coil - Aluminum Profile 6060 6061 6063 6082 Grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Profile 6060 6061 6063 6082 Grade Aluminium ProfileDescription:

Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

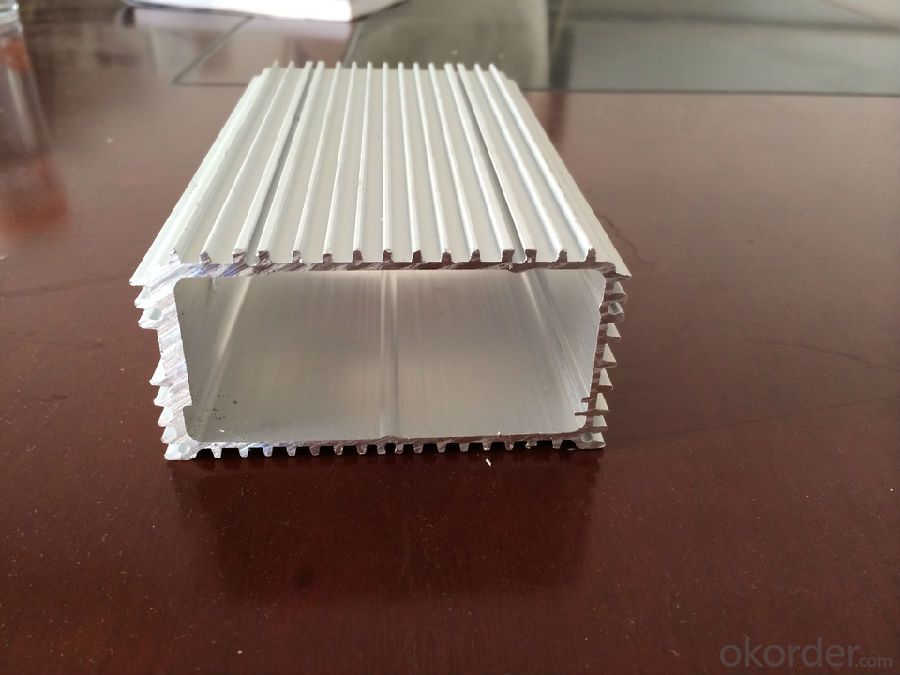

3.Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile Images:

4.Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can aluminum coils be used in solar panel installations?

- Yes, aluminum coils can be used in solar panel installations. Aluminum is a popular material choice due to its lightweight, corrosion resistance, and excellent thermal conductivity. It is commonly used for manufacturing solar panel frames and mounting systems, providing durability and cost-effectiveness in solar installations.

- Q: I planned on making heart shaped pancakes for Valentine's day - is it ok to use aluminum foil as the mold for it? If so, how should I go about it?

- If you are using a frying pan on a gas stove - yes. I fold tin foil into a strongish ribbon then form the shape I want: hearts, gingerbread men, etc. Make sure the pan is fairly warm before you put the tin foil shape in remove the shape as soon as the pancake is set, but before you flip it. You can trim the little splashes before serving. HOWEVER - there are reusable shapes available at many kitchen supply stores. They are not very expensive are permanent additions to your kitchen.

- Q: How to calculate the dosage of paint for aluminum coil coating? If the weight is 1 ton, the density 2.71 and the thickness 0.12mm, how much paint is needed?

- Coating surface area S*0.12(thickness)*ρ(density) / solid(paint solid)=actual paint consumption brush and roller paint: 100% spray paint: calculated value*70%

- Q: Are aluminum coils suitable for construction purposes?

- <p>Yes, aluminum coils can be used for construction. They are valued for their lightweight, corrosion resistance, and high strength-to-weight ratio, making them ideal for applications such as roofing, facades, and structural components. Aluminum's malleability allows for easy shaping and forming, which is beneficial in various construction projects. It's also sustainable due to its recyclability, reducing environmental impact.</p>

- Q: i have about 100lbs of aluminum blocks and scrap.

- There is a BIG difference between the recycling refund on aluminum containers and the scrap value of other aluminum. The recycling refund is based upon deposits on beverage containers. It used to be that scrap dealers mentioned the amount of the deposit refund PLUS the scrap value of the cans. Now many of these slimy scuzz butts only REFUND the deposit and do not pay the scrap value! They keep that scrap payment for themselves as a windfall profit! The scrap value of aluminum doors, aluminum eating utensils, and so on is a set price. You will get only scrap market value for those. It will be handled separately. Try, as I did, putting aluminum foil in the drink cans and see what happens! I was doing it only because the aluminum foil was aluminum and would go to the same place. But, they have a count scanner that assesses the number and weight of the aluminum cans you bring in (the one I went to had it mounted above the conveyer belt where the shredder accepts the cans) and they can compare the weight of all of the cans to the count or basket capacity. Also, if they find shredded aluminum foil in the bin, they can analyze approximately who brought it in. They are also wise about putting water in the cans so they are heavier, but I never did that.

- Q: How are aluminum coils protected during shipping?

- Aluminum coils are typically protected during shipping by being wrapped in a layer of protective film or paper, secured with strapping or bands, and then placed on pallets or in crates. Additionally, they may be enclosed in metal or wooden containers to provide further protection against external damage during transit.

- Q: Are aluminum coils suitable for food storage containers?

- Aluminum coils are indeed appropriate for food storage containers. This material is highly favored for such containers because of its many beneficial qualities. To begin with, aluminum is lightweight, which makes it easy to handle and transport. Moreover, it possesses excellent thermal conductivity, allowing for quick heating or cooling, making it perfect for storing both hot and cold food. Additionally, aluminum is resistant to corrosion and does not react with acidic or alkaline foods, ensuring that the taste and quality of the food remain unaffected. Furthermore, aluminum is an environmentally friendly choice as it is sustainable and can be recycled. However, it is worth noting that aluminum containers should be coated with a food-grade lining to prevent any potential interaction between the metal and the food, particularly with acidic foods. In conclusion, aluminum coils are a suitable option for food storage containers due to their lightweight nature, thermal conductivity, resistance to corrosion, and recyclability.

- Q: An they say aluminum can cause breast cancer in some.

- No, that's crap. If that were true, any somewhat clean person who wears deodorant would have breast cancer. So, no.

- Q: Can aluminum coils be used in the manufacturing of furniture?

- Yes, aluminum coils can be used in the manufacturing of furniture. Aluminum is a lightweight and durable material, making it ideal for furniture production. It is commonly used in the construction of outdoor furniture, as it is resistant to rust and corrosion. Aluminum coils can be formed into various shapes and sizes to create different furniture pieces. Additionally, aluminum can be easily customized and finished with different coatings or paint to match any desired aesthetic. Overall, aluminum coils are a versatile and practical choice for furniture manufacturing.

- Q: Can aluminum coils be painted or coated?

- Yes, aluminum coils can be painted or coated. Aluminum is a versatile material that can be painted or coated with various finishes to enhance its appearance and protect it from corrosion. The process of painting or coating aluminum coils typically involves cleaning and preparing the surface, applying a primer, and then applying the desired paint or coating. The type of paint or coating used will depend on the desired finish and the intended application of the aluminum coil.

Send your message to us

Customized Color Coated Aluminum Coil - Aluminum Profile 6060 6061 6063 6082 Grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords