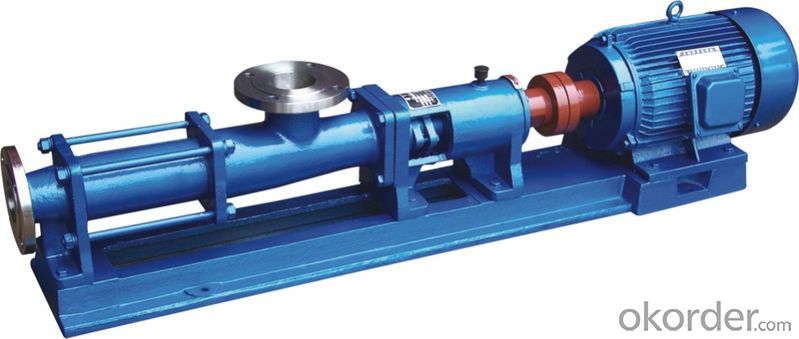

Positive Cavity Screw Pumps for Sewage Sludge and Polymer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Positive Cavity Screw Pumps for Sewage Sludge and Polymer

◆ Wide application, it can be used for conveying of flowing materials, even non-flowing materials

◆ Continuous conveying, small pulsating quantity

◆ The media is not stirred in the pump and is free from squeezing and cutting

◆ The flow is in direct proportion to the rotating speed, variable output, measurement feeding

◆Elastic stator, certain abrasion resistance

Conveying Medium of Positive Cavity Screw Pumps for Sewage Sludge and Polymer

◆ Various viscous media (the highest viscosity reaches 106 mm2/s)

◆ Fluids with various concentrations and dewatered and dried materials

◆ The media containing solid particles, fibers and suspended solids

Multiple Configurations of Positive Cavity Screw Pumps for Sewage Sludge and Polymer

◆ Materials: The parts can be made from different kinds of metals and rubber materials

◆ Drive: Motor speed reduction, motor speed regulation, mechanical speed regulation

FAQ

◆Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

◆Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

◆Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

◆Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

- Q: I have had this water pump changed 2 times in 5 years is this normal for this car? It has a v6 motor.

- 1. Remove any radiator shroud, or any cowl obstructing the fan, radiator, and water pump. 2. using a pair of large pliers, take off the clamp on the lower radiator hose at the water pump and drain the coolant into a container. Make sure the motor is COLD, room temp, when you do this. 3. Remove the other hose. 4. Remove the cooling fan using an air hammer or a large adjustable wrench. This part is tricky, unless your fan is bolted on with 10 mm bolts, then you lucked out. 5. For step 4, leave the belt on, it will make it easier to remove the fan. 6. If you have a V-8 LT-1, then you have 4 13 mm bolts. Be careful not to damage your distributor which sits under the pump (nice design GM) 7. Using a razor blade, remove any gasket on the inlet and outlet on the block. 8. Apply a thin layer of gasket sealer on the gaskets for the new pump. 9. Install the pump, and its bolts. Use locktite if you have some on the bolts, medium strength. Tighten the bolts to about 90 in/lbs 10. install the pully, and fan. (again, tricky) 11. Install the belt. 12. put lower radiator hose back on (leave off upper) 13. pour 1/2 a bottle of Dex-cool coolant in the radiator 14. fill bottle up with 1/2 water, 1/2 coolant, and pour it into the reservoir. 15. If necessary, get new bottle of coolant, and pour it into the UPPER RADIATOR HOSE, this will help bleed air out of the system. 16. keep filling upper hose, and radiator until it stops bubbling down and basically overflows. 17. install upper hose. 18. make sure the radiator is full and system has no air pockets. Check to see if the upper radiator hose inlet has a bleeder valve. If it does, use a pair of pliers and open it, and watch coolant in radiator drop, then fillit up again. The V-6 has one, not sure about V-8. 19. put radiator cap on, and resevoir cap. 20. run motor, check for any leaks. 21. drive, if vehicle is overheating and there are no leaks, there is still air in the system. Wait till it cools down and bleed air again.

- Q: Hey all--I just paid $900 at the Volkswagen dealership to get my timing belt, water pump, rollers, and air pump replaced. Is that a good deal? Also, how does the timing belt replacement relate to performance? I noticed my car was a little faster than before (maybe it's because I was driving another car for 2 days).

- You made a wise decision to have your car timing belt/water pump changed at the dealership as they are major components. I believe the $900 was well spent and will serve you well for many more years of safe driving. Unless the old belt was loose or slipping, thus possibly causing the valves to open at wrong timings, I don't think you will notice any difference in the car performance after the replacement, especially if it was a preventive maintenance at the recommended mileage. But I do believe you will feel some difference in terms of the engine smoother acceleration and responsiveness. The $900 spent can really do wonders sometimes, at least in your mind.

- Q: My truck has been over heating, and I cant figure out whats going on...the only thing that gets really hot is the upper radiator hose, and the radiator....I just noticed there was a plug unhooked from the water pump, what does that do? Or maybe it could be the thermostat? It just overheats, and when I park it, it wont start half the time, usually I can let it cool off and go, but sometimes it just dies and I have to let it cool off and jump it off.

- I doubt its your water pump. That plug may have been just the temperature sensor. Definitely sounds like a bad thermostat. Replace it. They aren't expensive at all. Letting your truck over heat does serious irreversible damage to the engine. You may have significantly shortened the life of your engine already. Just replace the thermostat when the truck is COLD, never when its hot. If it still overheats with the replacement thermostat, your radiator may be clogged.

- Q: I replaced the water pump on my 1997 acura cl 3.0 v6 vtec. I set the timing how alldata said to. (Lined up marks on timing drive pulley and both cam pulleys) and put it all back together. Now when I start it the motor runs rough for about 45 seconds then it smooths out but won't rev past 3000 rpm. What are some possibilites it could be?

- looks like the force belt broke, or is slipping. The force belt connects the engine to numerous aspects, like your alternator which rates your battery, the water pump, which pushes the coolant around the engine and radiator to relax the engine, and your skill guidance pump, which pressurizes the hydraulic fluid to your skill guidance. do no longer force the motor vehicle back till you fix it. you're able to desire to heavily blow out the motor by using over heating it.

- Q: We are leasing land from a friend to put horses on. We're in the process of building a barn. We don't want to run water out there because its too much trouble for the meter and everything, but someone said to get a water pump and pump the water from the pond and filter it and use it. I have no idea what all we need or what kind of pump to get. Helpp!

- flow to sears and get a shallow nicely pump that has a foot valve and runs on 115vac consistent with probability a a million.5 hp ..if the top(the uphill area plus the pipe loss ) gets to sizeable you're able to desire a lager hp yet a a million.5 with a 25 ft of head could supply 9gpm at 40 psi . Oh confident is that's a closed gadget be certain an get a intense stress shrink off change..they're real decrease priced... from the E..

- Q: can a failing water pump sound like rattling or popcorn until the motor begins to over heat? the sound is nearthe waterpump. it goes away once the temp starts to overheat.the temp will get near redline then go down to normal and then start creeping up again. thanks for any replies.

- Yes it can! I am curious though if what you are hearing is a really bad water pump or spark knock due to excessive heat or possibly a blown head gasket. Remove the belt and shake the pulley on the water pump. If it moves or rattles at all, then it is probably bad. Seems strange that it hasn't tossed the belt off though if it were that bad. Worth looking though, testing is free, parts are not....

- Q: What is a 1 inch water pump?

- The caliber of the water inlet and outlet pipe is 1 inches of water pump,

- Q: ok im ready to install my new water pump but it has to gasket in the package i no where one goes it shapes to the water pump but i dont no if the other one is used, and also where does the o ring go in the big hole in the center does it have to be pushed down into a seem or something and do the to out side holes need o rings as well, and does the hermonic balancer seal need to b replaced

- The water pump should come off the block with 4 bolts, the gasket goes between the body and rear plate. The o- ring fits onto the transfer tube that travels between the valley of the block. Add a little lube to it to make installing the pump and cover easier. The lower t belt gear should slide off easily, if not a bit of heat may help, careful not to break the oil pump (front end of block). The upper cam gears are best loosened slightly while the belt is still installed. If not try slipping the old belt over the gear and holding the outside of the gear/ the belt. Air tools may be required due to torque required.

- Q: What is the difference between a low pressure pump and a high pressure pump?

- The specific speed of the high pressure pump is relatively smaller than the speed.Lift is not the same, the same flow, high pressure pump head high.Pump and shaft materials are not the same, high pressure pump raw material demand is higher, to be able to accept greater pressure and torque.The size is different, the pump body of high pressure pump is larger.Bearings can also be different, low pressure pumps are rolling bearings, and high pressure pump power, then some pumps are selected sliding bearings.The support method can also be different, the low-pressure pump is the pump foot support, but the high pressure pump can be the intermediate support.

- Q: I don't want to have to rent or purchase a electric pump to pump the water out of my pool so are there other ways to get the water out besides the obvious (a bucket and alot of people). I am really tight on money so purchasing a device to do the work isn't a real option but I really need to drain the pool without damaging it.

- I have what is called a sump pump that I drain my pool with it works great. Ask a friend or relative if they might have an old one laying around. The sump pumps are generally used for pumping water out of basements when they flood but they work great in pools. I have 2, if you were near I would give you one

Send your message to us

Positive Cavity Screw Pumps for Sewage Sludge and Polymer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords