Portable Manual Edge Banding Machine For Wood Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Portable Manual Edge Banding Machine For Wood Products:

This Kind of Manual Edge Banding Machine is our main product of Edge Banding Machine Series. With comprehensive range ,it includes automatic edge banding machine, semi-auto edge banding machine ,automatic shaped edge banding machine and so on .As an important process in panel furniture and cabinet making process ,edge banding takes a great role in determining the quality ,price and level of furniture. Edge banding process will embellish the profile of furniture, protect the corner from wearing out, avoid the veneer lifting, while transferring and using. Besides, edge banding is also a way to proof water and harmful air, which may destroy our health .VE series edge banding machine is able to process chipboard, MDF board, and other manmade board with with PVC, melamine and veneer .We produce kinds of edge banding machines to meet different needs of our consumers .

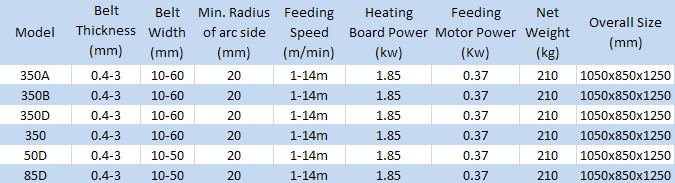

Specifications of Portable Manual Edge Banding Machine For Wood Products:

Advantages of Portable Manual Edge Banding Machine For Wood Products:

1. Easy operation.It can band the straight edge

2. Feedstock use the frequency transformer to adjust the speed

3. Having the auxiliary heating to ensure the glue flows smoothly

4. Woodworking Edge binding Machine with special design for glue systems, structural stability, long service life, coating uniformity and it will not leak glue

5. Multi-functional, can adapt to a variety of materials and sizes to provide a straight edge inside the arc, outside the arc, with curves and with circle

6. Automatically controls heat to reach set temperatures.Speed control can adjust banding speed to work at your pace

Package of Portable Manual Edge Banding Machine For Wood Products:

- Q: The formula is that the PVC and calcium powder are one to one. Is there any pigment diffusion or a color stabilizing material that can be added?

- PVC edge banding method is not white, the content of calcium carbonate is not too high.PVC edge banding is mainly made of PVC and calcium carbonate, plus additives, and if the content of calcium carbonate is too high, there will be banding, white, bending, white and other phenomena, it is proved that such products are poor quality.

- Q: 9 eco plates can edge it?

- Yes, it is a kind of material used to protect, decorate and beautify the furniture, plates and sections. It can make the furniture appear clear and colorful. If the process is good, the problem is not large. But the edge of various plates is different (due to the different thickness of the plate). Where to buy plate, who will be the edge banding?. Remember! Good steel used in the blade, to superior material, buy Decorative Building Materials website, choose some good material, use also save worry and effort.

- Q: Custom wardrobe edge is not good, sunny taste is very heavy, I would like to use glass glue to wipe the corner of the side, do not know if it is feasible? The cabinet is a wall, knocking out the pity, have been more than a year, the winter is almost what have no taste, a sun is very smelly, but not pungent odor.

- I suggest you do not use glass glue, you can use the adhesive, so it would not fall! Because production wardrobe manufacturers also use super glue stick to you!

- Q: The main reasons of edge banding degumming

- The main reasons are as follows:1, edge degumming is the main processor is too thin especially PVC edgebanding gum (agent) coating is too thin, and the decline of the hot melt adhesive affinity, which is one of the main reasons of the edge degumming.2, is the technical problem of edge machine temperature does not reach the predetermined temperature, causing sticking edge and hot melt adhesive glue is not good, the general requirements of the temperature at 180 ~ 210 degrees, can be adjusted according to the operating environment temperature sealing machine. This is mainly to look at the problem of technicians, manufacturers must strictly check, this is the problem of manufacturers.3, that is, the edge of the machine is too thin glue, originally did not produce a qualified edge banding. This is also an important reason, because the temperature and glue is too thin, causing the phenomenon of degumming is also common, you can increase the amount of glue to solve. The manufacturer's main problem is the manufacturer's responsibility. Everyone wants to think about it.4, uneven plate may also cause banding off, this is also must pay attention to the problem, appear this reason can only explain the installation technical problems.

- Q: I do Aluminum Alloy edge cabinets with more but do not know what a good play I've been playing rubber sealant but I found people playing is a kind of transparent glue and dry hard also do not know what is the glue please help thank you.There is aluminum alloy edge banding, how can you precisely cut 45 degrees angle, I cut all right, not very good mouth how to do, there are burrs on the incision?.

- Ergo.1925 acrylic structural adhesive, environmental protection, high strength AB abInstead of welding, high strength, waterproof adhesive ergo1925 Description: This is a low odor acrylic structural adhesive, can be used for bonding metals such as aluminum, steel, brass, stainless steel and aluminum alloy and ferrite, and the combination of these commonly used plastic, plastic. It is a two component system with a mixing ratio of 1:1, but not sensitive to mixing ratio, and is also suitable for manual mixing.

- Q: Can the kitchen cabinet carbonization door plank do the acrylic edge banding? Optimistic about a set of kitchen cabinets, aluminum alloy plate, carbonized board. I don't like aluminum alloy hemming. Optimistic about color and brightness of carbonized board. Do not know the carbonized board is good to do acrylic edge?

- The landlord is a bit difficult, because the carbonization plate hardness is relatively high, with normal cutting devices to avoid cutting edge collapse, so usually used to wrap aluminum edge chipping, aluminum edge back hook part can cover up the small, if you want to use acrylic edge would need very good cutting equipment, and sealing machine requirements are relatively high, in the edge sealing machine before the first clear edge, also will bring the edge collapse, so unless there are special equipment manufacturers can do.

- Q: The attic is covered with a multilayer board that needs cutting and the cut part needs to be coated with edge coating.What kind of paint is it with edge coating? Ordinary alkyd paint, okay? Or special carpentry paint?

- It's a kind of wood paint

- Q: Ask everybody a thing, how much is that cloth sealing edge strip one meter?

- Hello, which kind of edge banding do you prefer, solid wood or PVC? What are the width and thickness?,

- Q: Where is the construction of the unsupported end plate in the 11G101-1P95 page?

- Personal understanding is that the thickness of the cantilever plate reinforcement should be banding structure, such as thickness > 150mm, raft raft out of the base, the cap width of the election, and so on. The 'unsupported board' is not very good.

- Q: What are the reasons for the breakage of plastic bags? What is the reason that the material is BOPPCPP and the heat sealing edge is damaged?

- When the edge is hot, the edge sealing machine or manual time is too long, because the temperature is uncontrollable, but the current and time are controllable

1. Manufacturer Overview

| Location | Guangzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2 Million |

| Main Markets | Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shunde; Guangzhou |

| Export Percentage | 5% - 10% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Portable Manual Edge Banding Machine For Wood Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords