Multi-Function Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Multi-Function Automatic Edge Banding Machine

1. Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

2. Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

3. It adopt the imported original electrical machinery, each performance is better.

4. It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

5. Blow up and down the side, surface polishing up and down and so on.

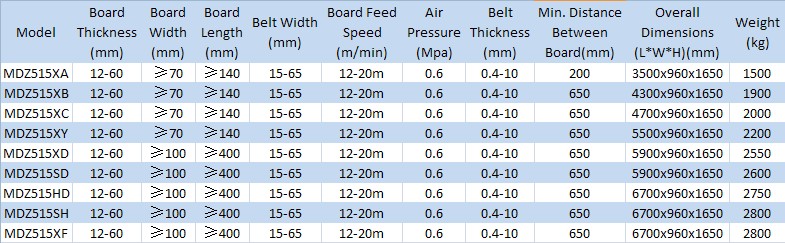

Specification of Multi-Function Automatic Edge Banding Machine

Advantages of Multi-Function Automatic Edge Banding Machine

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

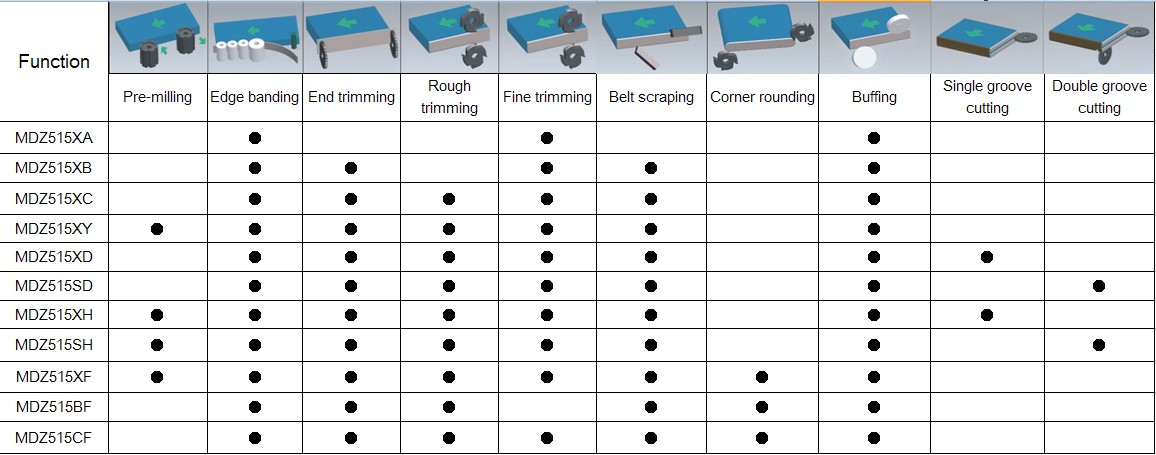

Main Functions of Multi-Function Automatic Edge Banding Machine

Packing of Multi-Function Automatic Edge Banding Machine

- Q: How to seal the frozen dumpling packing bag?

- It can be done by hand press sealer. Also depends on the bag material, if it is nylon composite, the sealing machine model requirements. If it is another material, no problem... Also look at the size of the dumplings and what size bags will be made in the future because the large size of the bags will be larger in length. For example, within 500 grams of 20CM can be, 1000 grams of the best 25CM within, 2.5KG to more than 30 CM.

- Q: TV background wall mosaic tile, generally with what material edge, edge with what do not want to use the artificial marble, feeling too heavy, too Chinese

- Also has synthetic material lines, very light, variety, and some of the wallpaper sold on behalf of

- Q: Integrated ceiling sealing edge role, not surrounded by edge can be?

- The aluminum buckle does not need glue to seal, one is the metal processing neat, the crevice is small and even, is not necessary, two is by the metal keel card, the assembly and disassembly is convenient, easy to open. Periphery also does not need to hit the rubber, hits is not good, but is ugly.

- Q: Please advise me. All my predecessors, how can the furniture edge of knowledge, the more detailed the better. Thank you!PVC furniture edge banding in the production of the factory is directly in accordance with the requirements of customer specifications, or first produce a large edge coated paper, processing? How much is the general quantity? And what about a case of boxes?

- Edge is a decorative role, is a kind of PVC material, generally has a thickness of 1.0,1.5 two with more than the quality manual, edge durability, appearance is not the machine automatically after all hand edge edge, insufficient force smooth uniform, easy pressure is not formed or not a virtual reality phenomenon. So buy furniture, try to buy machine edge, do not covet cheap!

- Q: Who can tell me the name of this kind of edge sealing wood paper? Anyway, not called edge banding, Taobao only the kind of 1MM thick PVC, right. That glue can not stick, it will rise, this thin is also wood grain, glue can be affixed to the board, can not afford to alice. I don't know what it's called. I can't find it on Taobao. There's only solid wood on Taobao. I'll buy this thin one. Who can tell me its name? Where can I buy it?

- Veneer Edge banding. There are many treasures in Amoy 1. Hope to help you, thank you, please adopt

- Q: What is the best glue for solid wood sealing?

- White latex will do

- Q: The difference with the closing edge?

- With the closing edge actually Datong small guide.The edge can be understood as.Can not be understood as edge.

- Q: How to seal the edge of panel furniture?

- With manual curve edge machine ah, the new 5-6W or so, do the necessary machine board furniture ah. If your worker skill is good enough, you can completely seal yourself by hand. Use a hot blower over 1000 degrees. First, the edge banding will be glued on the edge sealing machine and then sealed.

- Q: 40Cm thick raft, straight through 12 steel double double direction, outer edge steel reinforcement length

- No less than 10 cm. Regular 15 centimeters will do

- Q: Full automatic edge banding machine, what price, thank you

- What kind of products would you like to make and what grade would you like?. I am doing wardrobe, edge are basically used in 2-3 mm, is used with pre washing, built 3, spent more than 130 thousand. Qingdao Naisen brand, product line overall full.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East; Eastern Europe; South Asia. |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 500-700 People |

| Language Spoken: | Chinese; English |

| b) Factory Information | |

| Factory Size: | Above 800,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | Middle |

Send your message to us

Multi-Function Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords