Manual Edge Banding Machine With Best Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Manual Edge Banding Machine With Best Quality

This Kind of Manual Edge Banding Machine is our main product of Edge Banding Machine Series. With comprehensive range ,it includes automatic edge banding machine, semi-auto edge banding machine ,automatic shaped edge banding machine and so on .As an important process in panel furniture and cabinet making process ,edge banding takes a great role in determining the quality ,price and level of furniture. Edge banding process will embellish the profile of furniture, protect the corner from wearing out, avoid the veneer lifting, while transferring and using. Besides, edge banding is also a way to proof water and harmful air, which may destroy our health .VE series edge banding machine is able to process chipboard, MDF board, and other manmade board with with PVC, melamine and veneer .We produce kinds of edge banding machines to meet different needs of our consumers.

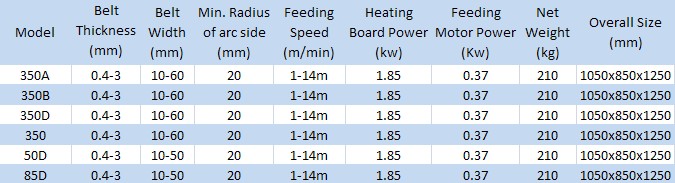

Specifications of Manual Edge Banding Machine With Best Quality

Advantages of Manual Edge Banding Machine With Best Quality

1. Easy operation.It can band the straight edge

2. Feedstock use the frequency transformer to adjust the speed

3. Having the auxiliary heating to ensure the glue flows smoothly

4. Woodworking Edge binding Machine with special design for glue systems, structural stability, long service life, coating uniformity and it will not leak glue

5. Multi-functional, can adapt to a variety of materials and sizes to provide a straight edge inside the arc, outside the arc, with curves and with circle

6. Automatically controls heat to reach set temperatures.Speed control can adjust banding speed to work at your pace

Package of Manual Edge Banding Machine With Best Quality

- Q: Would you please tell me how it works with a portable edge sealing machine? It sells at around 2600 yuan in Taobao,

- Melamine board staff is the sealing effect is not very good, with adhesive to white edge solid paste, with a rasp rest, and diluent scrub.

- Q: How does Genesis seal edges and how to cheat scripts?

- It's too complicated to ask. Who gives you the answer?!

- Q: 12 mm sunshine board with what specifications of edge banding?

- The standard width of the sunlight board is 2.1 meters, and the length of the stock is usually 6 meters. The manufacturer can make the order.

- Q: Who knows in the ambry, what does the edge banding of lacquer paint panel have? Which kind is commonly used in the market? Thank you

- Our company's paint cabinet door panels are mostly done Gong side, edge type is the whole, or do aluminum alloy edge.

- Q: The best window tile the edge? Answer urgently. Thank you

- I looked at the front of the reply, feeling is the choice of marble is better, you can choose black Jinsha, white jazz, beige marble series, although it is said that the marble radiation, why grade decoration will choose it, but not the wall ground in large area this does not matter, the threshold sill board is best choice of natural stone stone, artificial stone appearance was flattered, no more than the hardness of artificial stone, natural stone, with long scratches easily into the dust, not for a long time to, if it is because of the natural stone is not long enough for two pieces of good, on the not so obvious, the two pieces or three pieces can be, the most important the future is on the table cloth mat can be customized, the seam is even less to

- Q: Please tell me how to adjust the thickness of edge banding. Also help to explain the R knife, profiling wheel, taper wheel, and the side pressure wheel. Thank you very much

- Hello, first of all thank you for your trust in me. According to your question, I simply said I understand the edge banding machine knowledge, incorrect place, please forgive me. You are using automatic linear edge banding machine is right, edgeband thickness regulating tape feed mechanism need (mainly for guiding), horizontal sliding seat trim on the (horizontal / back), in order to get the ideal arc R. R R and R knife cutter blade, the knife edge is concave arc shape, the arc cutting edge is the tool, the tool will have different arcs in different sizes, most edge machine is used R2 arc, and the different is flat repair knife, the blade is flat, no arc. The profiling wheel is actually the vertical datum of the tool. When the plate is moving, the copying wheel is tightly attached to the plate to ensure the cutting accuracy of the cutting edge. You said that the taper wheel is not the part of the coating or the trimming part. If it is the part of the coating, the two cone wheels are usually set for the purpose of compacting the edge of the edge band with the upper and lower sides. When it comes to trimming, it works the same way as the copying wheel, unlike the copying wheel because it is a horizontal benchmark used to control the amount of cutting in the horizontal direction of the tool. Method of adjusting a lot of details, here is not to say, the general idea is that you can use a long plate, the section saw Qi, not sticky glue edgeband, so he went to the middle of the machine and then stopped, and then the profiling wheel and baroclinic wheel by flat plate to adjust the locking position then, on both sides of the cutting tool is adjusted to the sheet, cutting size can according to production needs to adjust. I don't know if I can help you with anything. It's always difficult to express it. I hope it will help you!

- Q: No cutting fault of edge sealing machine

- The rear stroke switch is out of order

- Q: Types of edge banding

- Acrylic edge strip is made of acrylic extrusion molding. PMMA, commonly known as organic glass, also known as acrylic (Acrylic), from this name, you may not know what kind of material it is, and no way of knowing what elements it is made of. The polymer chemical name of transparent material called polymethyl methacrylate, acrylic plate often said is poly methyl methacrylate (PMMA) plate, which is composed of methyl methacrylate monomer (MMA) polymerization. High transparency. Organic glass is the best polymer transparent material at present. The transmittance is 92%, which is higher than that of glass. The lamp is called the artificial sun solar quartz is done, this is because the quartz can be completely through ultraviolet. Ordinary glass can only penetrate 0.6% of ultraviolet light, but organic glass can pass through 73%. Shanghai plastic sealing edge adopts imported production equipment and raw materials, good toughness, products edge and face color, with anti oxidation and anti ultraviolet effect, and high temperature, cold resistance. Mainly suitable for high-grade furniture, cabinets, doors, shelves, bedroom suites, office furniture, according to the product specification or customer requirements to provide a variety of sizes, thickness can range from 0.5mm to 8mm, width from 9mm to 180mm, priority technology, edge expert.

- Q: How to seal the edge of panel furniture?

- With manual curve edge machine ah, the new 5-6W or so, do the necessary machine board furniture ah. If your worker skill is good enough, you can completely seal yourself by hand. Use a hot blower over 1000 degrees. First, the edge banding will be glued on the edge sealing machine and then sealed.

- Q: Can the reinforced edge of the raft foundation be mechanically connected?

- I think you should have a lightning strike on the line, and the cutting board on the line is connected in a circle,. Welding on the top of the steel bar on the line, if the mechanical connection, a class of joints in the tensile zone should be staggered 50%, in the compression zone

1. Manufacturer Overview

| Location | Guangzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2 Million |

| Main Markets | Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shunde; Guangzhou |

| Export Percentage | 5% - 10% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Manual Edge Banding Machine With Best Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords