Manual Edge Banding Machine For Wood Working

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pcs pc

- Supply Capability:

- 10000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Manual Edge Banding Machine for wood working

This Kind of Manual Edge Banding Machine is our main product of Edge Banding Machine Series. With comprehensive range ,it includes automatic edge banding machine, semi-auto edge banding machine ,automatic shaped edge banding machine and so on .As an important process in panel furniture and cabinet making process ,edge banding takes a great role in determining the quality ,price and level of furniture. Edge banding process will embellish the profile of furniture, protect the corner from wearing out, avoid the veneer lifting, while transferring and using. Besides, edge banding is also a way to proof water and harmful air, which may destroy our health .VE series edge banding machine is able to process chipboard, MDF board, and other manmade board with with PVC, melamine and veneer .We produce kinds of edge banding machines to meet different needs of our consumers .

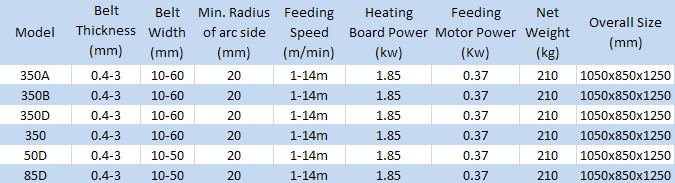

Specifications of Manual Edge Banding Machine for wood working

Advantages of Manual Edge Banding Machine for wood working

1. Easy operation.It can band the straight edge

2. Feedstock use the frequency transformer to adjust the speed

3. Having the auxiliary heating to ensure the glue flows smoothly

4. Woodworking Edge binding Machine with special design for glue systems, structural stability, long service life, coating uniformity and it will not leak glue

5. Multi-functional, can adapt to a variety of materials and sizes to provide a straight edge inside the arc, outside the arc, with curves and with circle

6. Automatically controls heat to reach set temperatures.Speed control can adjust banding speed to work at your pace

Package of Manual Edge Banding Machine for wood working

- Q: Panel type furniture automatic edge sealing machine. How many grams of hot melt adhesive does it need per meter?

- Hello, this question is a little general.It depends on the thickness and quality of the board you seal.There is the edge of the machine, adjust the amount of glue will vary.In general, the edge banding machine is not large glue, good edge banding opportunity to glue some, and evenly coated.If you need any equipment, you can contact me by telephone.

- Q: What edge does solid wood cabinet use?

- A kind of wooden gum called an instant. In fact, you can use a lot of glue, many people like to use this glue

- Q: Melamine laminate veneer how edge?

- With the edge banding, which depends on what kind of edge, the general plate furniture edge with PVC glue strip, and if you want some noble, with aluminum alloy edge.Melamine board has many characteristics, mainly reflected in three aspects:The first aspect is beauty. The melamine plywood has natural texture, clear wood, wood and wood can Bimei, all over the world, and the surface is no color, product design is exquisite, modelling color collocation.Second aspects - quality. Melamine plywood has self extinguishing, wash resistant, wear-resistant, moisture-proof, anti-corrosion, anti acid, anti alkali, non stick dust, not because of the wall and damp moldy black phenomenon.Third aspects - Environmental protection. Melamine plywood need not be painted, in the construction of paint after painting and paint costs, but also to avoid paint on the human body unhealthy odor and carcinogenic substances.

- Q: How does Genesis seal edges and how to cheat scripts?

- If you don't, you have to study. Two main points1. Learn how to use the programming language2, in terms of edge, you have a set of programs for the use of Genesis software? It is good to write the corresponding program directly to the common character of your bandingBut I guess you can't do anything yet Otherwise, I wouldn't ask such a question. I hope my answer will be helpful to you

- Q: What is the composition of the edge hot-melt adhesive?

- Vinyl acetate copolymer (EVA) as the main material, adding tackifier and other components of the solid binder, with fast bonding, high strength, aging resistance, no poison, good thermal stability

- Q: How about the semi-automatic edging machine and the three row drill?,

- So-so。 The main service is not good

- Q: What are the reasons for the breakage of plastic bags? What is the reason that the material is BOPPCPP and the heat sealing edge is damaged?

- When the edge is hot, the edge sealing machine or manual time is too long, because the temperature is uncontrollable, but the current and time are controllable

- Q: I am a furniture factory, need a lot, it is best to paint to dry is the best, the ash inside the shop, if the dry time is too slow for local repair will be dust, it will look at the dust, affect the quality of the product.

- Is the seal broken? Paint and paint is not the same, to go inside with the infiltration density board paint, fill the effect is not good, to what the people network to find a professional furniture repair.

- Q: Solid wood flooring is necessary waterproof paint edge?

- Solid wood flooring is generally not waterproof, but do not need to paint, you can regularly play a layer of floor wax, protect the floor.Before construction, solid wood flooring is best placed in advance in a well ventilated place, open the packing box, ventilate. We should pay more attention to the ventilation problems in the construction of the rainy season, so you can release the floor painting taste; can also minimize the rainy weather brought to the damp wooden floors, reduce the possible deformation, drum and Fengkuan is like when in use.In the wooden floor paved the best in use for a period of time after waxing, also called wax. In this way, the moisture remaining in the construction can be evaporated as much as possible. Extend the service life of the floor.Finally, when laying large core board, the wooden keel should be used to level the ground, and the wool board is divided into blocks, and each floor space is provided with 1cm seams, so that the moisture on the ground surface is easy to be distributed, and the wooden floor can be prevented from bulging. Clean the ground residual soil residue, may be appropriate to sprinkle some insect repellant, in order to prevent regeneration insects.

- Q: Is it true that Lushuihe doesn't do edge banding?

- What's the problem? My family is Lushuihe. What border banding?

1. Manufacturer Overview

| Location | Guangzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2 Million |

| Main Markets | Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shunde; Guangzhou |

| Export Percentage | 5% - 10% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Manual Edge Banding Machine For Wood Working

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pcs pc

- Supply Capability:

- 10000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords