Automatic Linear Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Automatic Linear Edge Banding Machine

1. Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

2. Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

3. It adopt the imported original electrical machinery, each performance is better.

4. It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

5. Blow up and down the side, surface polishing up and down and so on.

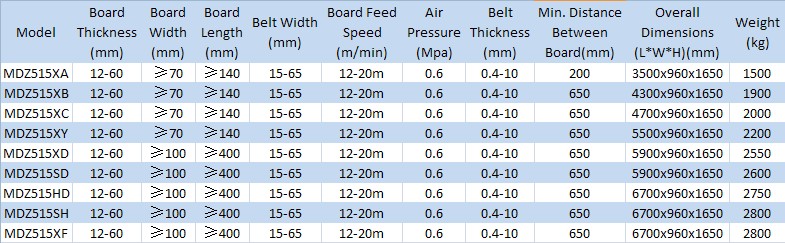

Specification of Automatic Linear Edge Banding Machine

Advantages of Automatic Linear Edge Banding Machine

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

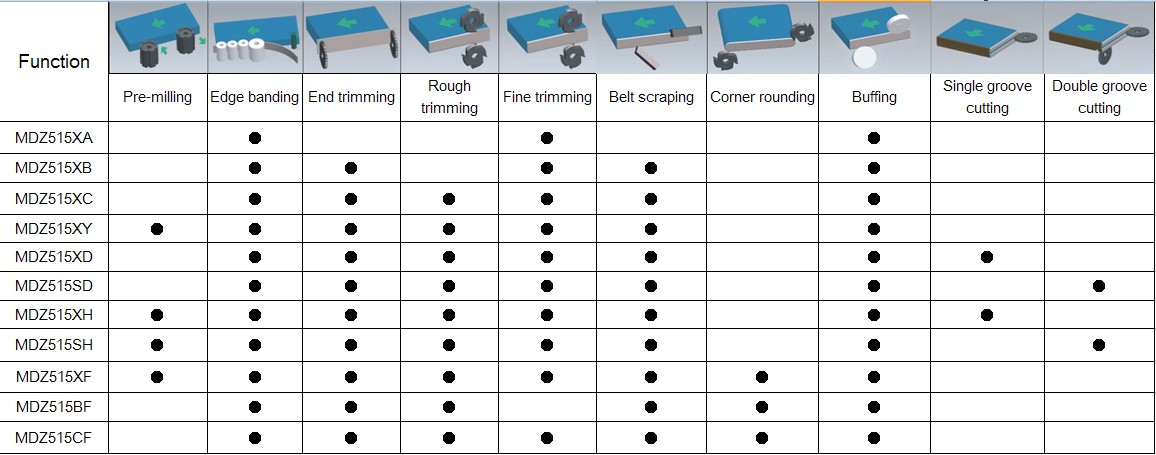

Main Functions of Automatic Linear Edge Banding Machine

Packing of Automatic Linear Edge Banding Machine

- Q: Whether or not the upper and lower frames of the solid wood composite door bear edges?

- Solid wood door is characterized by outstanding real word, I suggest you do not edge

- Q: Melamine density board how hand affixed edge strip?

- It's OK to use ordinary glue. It's nothing special. Decorative E station through the website of building materials shopping channel, there are many information about the plate, you can go and see.

- Q: What are the specifications of the side reinforcement in the raft edge construction? With gluten or gluten? Or using smaller steel bars?

- The side reinforcement is made of 14mm or 16mm in diameterAnswer supplementA lot of drawings are designed like thisAnswer supplementThe diameter and quantity of the reinforcement in the side structure are directly related to the thickness of the raft and the two-way main reinforcement

- Q: Cross stitch edge ornaments how?

- The embroidered figure leaves two or three, the rest are cut off, and then put two pieces of the same can repair the suture, suture when in fact it is best not to use the fishing line, because it is not just the line Yuntie, with cotton, nice and strong, the color edge of cotton to choose if you stitch, is cluttered with black or white, you try, definitely better than the suture line.

- Q: No cutting fault of edge sealing machine

- Check your sensors! I've met too

- Q: PVC sealing strip extrusion foam what is the reason?

- Raw material needs drying

- Q: My home closet is the use of paint free plate, at that time did not understand, the master fooled me to install the aluminum alloy edge banding. Ugly to death. Want to take it apart?. Please help God. Thanks again!

- Edge paint free plate can be changed, you go to the edge of paint free plate sales shop together with the choice of color and width, bought the white glue or adhesive sticker on it, but the welt is a live, they don't stick.

- Q: PVC what's the glue for the edge banding?

- UPVC special glue will do. It's cheap. About five or six dollars a bottle.

- Q: The acquisition of a large number of furniture factory waste edge quality requirements Gaobutaiduomu ash can be who?

- Do you want to play wood ash? How much is one ton? What about the contact details?

- Q: How about the iron edge sealing strip for IKEA curtain?

- This is easy to use without sewing. It's easy to cut out. Suggest that you can look at the instructions on IKEA how to write the specific steps, or ask IKEA directly related personnel, I hope my answer can help you oh.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | US$ 150 Million |

| Main Markets | 30.00% Europe 40.00% North America 30.00% Southeast Asia; Mid East |

| Company Certifications | CE; ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

Automatic Linear Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords