Portable Linear Curve Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Portable Linear Curve Edge Banding Machine

This Kind of Manual Edge Banding Machine is our main product of Edge Banding Machine Series. With comprehensive range ,it includes automatic edge banding machine, semi-auto edge banding machine ,automatic shaped edge banding machine and so on .As an important process in panel furniture and cabinet making process ,edge banding takes a great role in determining the quality ,price and level of furniture. Edge banding process will embellish the profile of furniture, protect the corner from wearing out, avoid the veneer lifting, while transferring and using. Besides, edge banding is also a way to proof water and harmful air, which may destroy our health .VE series edge banding machine is able to process chipboard, MDF board, and other manmade board with with PVC, melamine and veneer .We produce kinds of edge banding machines to meet different needs of our consumers .

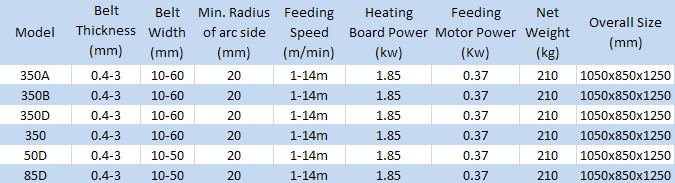

Specifications of Portable Linear Curve Edge Banding Machine

Advantages of Portable Linear Curve Edge Banding Machine

1. Easy operation.It can band the straight edge

2. Feedstock use the frequency transformer to adjust the speed

3. Having the auxiliary heating to ensure the glue flows smoothly

4. Woodworking Edge binding Machine with special design for glue systems, structural stability, long service life, coating uniformity and it will not leak glue

5. Multi-functional, can adapt to a variety of materials and sizes to provide a straight edge inside the arc, outside the arc, with curves and with circle

6. Automatically controls heat to reach set temperatures.Speed control can adjust banding speed to work at your pace

Package of Portable Linear Curve Edge Banding Machine

- Q: Mainly sealing veneer, requiring small odor, volatile

- Pauchie furniture edge glue is used Henkel glue

- Q: How does the floor arc close edge? With what edge?

- Gold clad wood plastic bag can be. It can also be inlaid and wrapped

- Q: Cross stitch edge ornaments how?

- Sew two pieces of cloth together with a fishing line. I don't have a video.. Otherwise, let me show you.. Let me practice a seal... Let me tell you.. The trick is to sew as casually as you can with your clothes.. The fishing line.. Not visible on the seam.. Got it? OK?

- Q: Which is better, the furniture edge, the button strip and the edge banding strip?

- Each one has his good points, edging good-looking but easy to fall off; buckle out but firm bonding

- Q: Please tell me how to adjust the thickness of edge banding. Also help to explain the R knife, profiling wheel, taper wheel, and the side pressure wheel. Thank you very much

- Not far from the glue pot, there is a digital mechanical manual adjustment handle. It can be adjusted to 1-4 mm thickness according to the thickness of edge banding. Be careful。 Now buy the edge of the market are not thick enough,.1 mm, are 0.8 or 0.9. Turn it down, please

- Q: I just touched furniture, this line, furniture edge, what should use glue, what glue good point.

- The furniture edge banding adhesive is a kind of adhesive specially used for sealing edges of artificial board. It is a solvent-free thermoplastic adhesive.Types of furniture edge banding adhesiveEVA (ethylene vinyl acetate copolymer resin) base hot melt adhesive, this hot melt adhesive can be divided into two types of filler and no filler. EVA as the base material is the most common furniture edge banding adhesive production technology, its main limitation is the poor heat resistance. With EVA hot melt adhesive edge of the use of plate furniture, ambient temperature can not be higher than 120 degrees C;POL YAMIDE (polyamide) based hot melt adhesive, which has excellent heat resistance and fast curing characteristics, the main drawback is expensive.HMPU (polyurethane) base hot melt adhesive, it is the best type of hot melt adhesive, high quality plate edge guarantee. It is expensive and requires a special method of use.

- Q: How about the iron edge sealing strip for IKEA curtain?

- This is easy to use without sewing. It's easy to cut out. Suggest that you can look at the instructions on IKEA how to write the specific steps, or ask IKEA directly related personnel, I hope my answer can help you oh.

- Q: What's the meaning of the "environmentally friendly edible wax" seal written on the wooden floor?

- The floor is wood pulp after treatment of wax exposed edges, is moisture-proof, not afraid of water.

- Q: How to install stainless steel edge banding?

- RBI glass adhesive

- Q: Cabinet box, use 18 fir finger to connect board, this still needs sealing edge??

- That doesn't need to be sealed. Fir finger board is good, it is generally treated by water, and varnish should be at least four times, this is certainly better than the moisture-proof board, moisture-proof board only moistureproof, waterproof.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | US$ 150 Million |

| Main Markets | 30.00% Europe 40.00% North America 30.00% Southeast Asia; Mid East |

| Company Certifications | CE; ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

Portable Linear Curve Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords