China Portable Manual Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of China Portable Manual Edge Banding Machine

This Kind of Manual Edge Banding Machine is our main product of Edge Banding Machine Series. With comprehensive range ,it includes automatic edge banding machine, semi-auto edge banding machine ,automatic shaped edge banding machine and so on .As an important process in panel furniture and cabinet making process ,edge banding takes a great role in determining the quality ,price and level of furniture. Edge banding process will embellish the profile of furniture, protect the corner from wearing out, avoid the veneer lifting, while transferring and using. Besides, edge banding is also a way to proof water and harmful air, which may destroy our health .VE series edge banding machine is able to process chipboard, MDF board, and other manmade board with with PVC, melamine and veneer .We produce kinds of edge banding machines to meet different needs of our consumers .

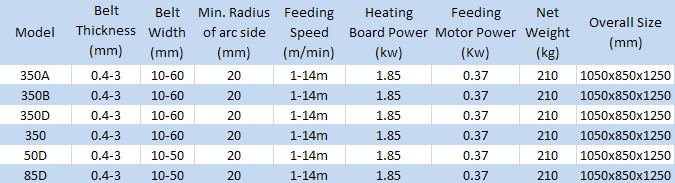

Specifications of China Portable Manual Edge Banding Machine

Advantages of China Portable Manual Edge Banding Machine

1. Easy operation.It can band the straight edge

2. Feedstock use the frequency transformer to adjust the speed

3. Having the auxiliary heating to ensure the glue flows smoothly

4. Woodworking Edge binding Machine with special design for glue systems, structural stability, long service life, coating uniformity and it will not leak glue

5. Multi-functional, can adapt to a variety of materials and sizes to provide a straight edge inside the arc, outside the arc, with curves and with circle

6. Automatically controls heat to reach set temperatures.Speed control can adjust banding speed to work at your pace

Package of China Portable Manual Edge Banding Machine

- Q: Custom wardrobe edge is not good, sunny taste is very heavy, I would like to use glass glue to wipe the corner of the side, do not know if it is feasible? The cabinet is a wall, knocking out the pity, have been more than a year, the winter is almost what have no taste, a sun is very smelly, but not pungent odor.

- Please refer to the classic distinction between "nail free glue" and "glass glue."It is recommended to use nail free gum:1, toughness bonding2, high strength: 3-6Mpa, high safety reserve3, it can be calculated:1 weight2, paste area3, shear capacity and safety reserve of adhesive (DrStik, no nail glue, 3-6Mpa)4, the back of the mirror is afraid of corrosion, and needs no corrosion free nail glue5, other considerations

- Q: Integrated ceiling sealing edge role, not surrounded by edge can be?

- Periphery must use the edge banding, these all are the matching use, for is beautiful looks, moreover also facilitates the gusset plate to close.

- Q: I do Aluminum Alloy edge cabinets with more but do not know what a good play I've been playing rubber sealant but I found people playing is a kind of transparent glue and dry hard also do not know what is the glue please help thank you.There is aluminum alloy edge banding, how can you precisely cut 45 degrees angle, I cut all right, not very good mouth how to do, there are burrs on the incision?.

- You can use the all-purpose adhesive, glass glue, if small area can use 502 plastic adhesive

- Q: Semi automatic edge sealing machine, one side coating and double face coating that good

- Side banding machine single face gluing has been enough, don't listen to sales flicker

- Q: Which kind of portable edge banding machine is easy to use?

- Portable edge banding machine, I have bought 3 units, or can say a 123. Specifically, that section of good, it depends on what you use boards, what to do. With MDF, density, board quality is good, the main line is sealed, with JBD80 this can be, about 2900 yuan. Seal curve edge multi speed JBT90, the price of 3500 yuan up and down. But if a wood particleboard, loose, or buy a double-sided adhesive. JBT102 the price is more than 6000, remember. I bought 2 from Luban woodworking machinery company, and it was smooth and sticky. Good luck。

- Q: I bought EO class solid wood paint free board to do furniture, but when the edge of the use of universal adhesive edge banding, a little green. I wonder if there is any other way to solve it. Paint with water paint or cover with other green paint, for example.

- Edge banding and solid wood lines can be solved, but solid wood lines are longer

- Q: Cross stitch edge ornaments how?

- The embroidered figure leaves two or three, the rest are cut off, and then put two pieces of the same can repair the suture, suture when in fact it is best not to use the fishing line, because it is not just the line Yuntie, with cotton, nice and strong, the color edge of cotton to choose if you stitch, is cluttered with black or white, you try, definitely better than the suture line.

- Q: Why does my kitchen cabinet door edge strip fall off, and the base board is particle board?

- The board is that particle board plate is melamine plate, commonly known as "particleboard, particleboard with PVC edge banding in general, the main role is to prevent moisture and appearance, internal contact sheet after sheet can prevent moisture, chemical gas overflow.There are several reasons for banding off:1. environmental problems caused by high temperature and high humidity;2., furniture manufacturing, edge coating coating uneven;3. furniture manufacturing, edge strength is not enough, not compressed;4. edge gum gum quality not too thin, too little or not uniform, resulting in degumming;5., edge glue quality does not work, cause degumming;6. furniture manufacturing, the edge sealing machine temperature is not adjusted well, resulting in edge melt melting is not ideal.The general judgment of reason, the edge will be torn off the back of observation, if there is no rubber plate, rubber sealing strip, not a layer of white or nearly transparent color is the edge sealing strip on the back, yellow gum coating, usually gum edge problem;Or no glue on the board, but there is glue on the edge banding. It is improper operation during manufacture or the quality of edge sealing adhesive;Simple solution: use blower to align the edge strip to blow hot air. When the back glue is soft or melted, press the edge banding on the original position. After a few minutes cool down, loosen again.

- Q: Cabinet edge quality, how to identify?

- Professional factory with linear edge banding machine to complete the plate edge, trimming, chamfering, polishing and other processes, the uniform coating (environmental heat Sol), stable pressure, straight line closure, after the completion of the edge smooth and delicate feel good, and small workshops with semi automatic edge banding machine, hand painted adhesive (even useful smell) pressure sealing paste with wallpaper knife and sandpaper trimming and polishing. Because of the uneven gluing seal, there will be the glue off the hidden danger. When buying cabinets, you may wish to touch the cabinet door panels and box edge, to see if the smooth and smooth. Box side edge light to see whether the wave fluctuations. Ask each panel is all around the edge, some manufacturers take the edge of the visual position, not visible or the junction of omission, it will cause the edge long-term moisture absorption swelling consequences, will also increase the formaldehyde emission.

- Q: PVC sealing strip extrusion foam what is the reason?

- Raw material has moisture. Exceed the standard

1. Manufacturer Overview

| Location | Guangzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2 Million |

| Main Markets | Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shunde; Guangzhou |

| Export Percentage | 5% - 10% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

China Portable Manual Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords