Automatic Straight Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Automatic Straight Edge Banding Machine

1). Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

2). Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

3). It adopt the imported original electrical machinery, each performance is better.

4). It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

5). Blow up and down the side, surface polishing up and down and so on.

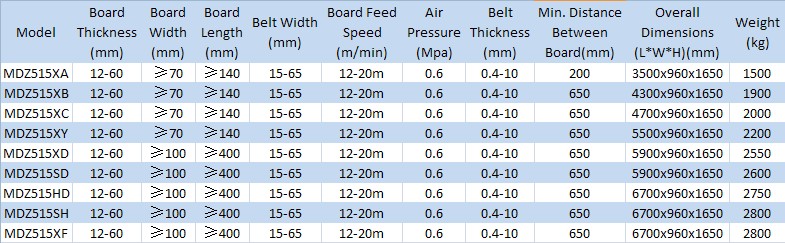

Specification of Automatic Straight Edge Banding Machine

Advantages of Automatic Straight Edge Banding Machine

1). Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2). The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3). End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4). Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5). Profiling unit, to make board end smooth and aesthetic.

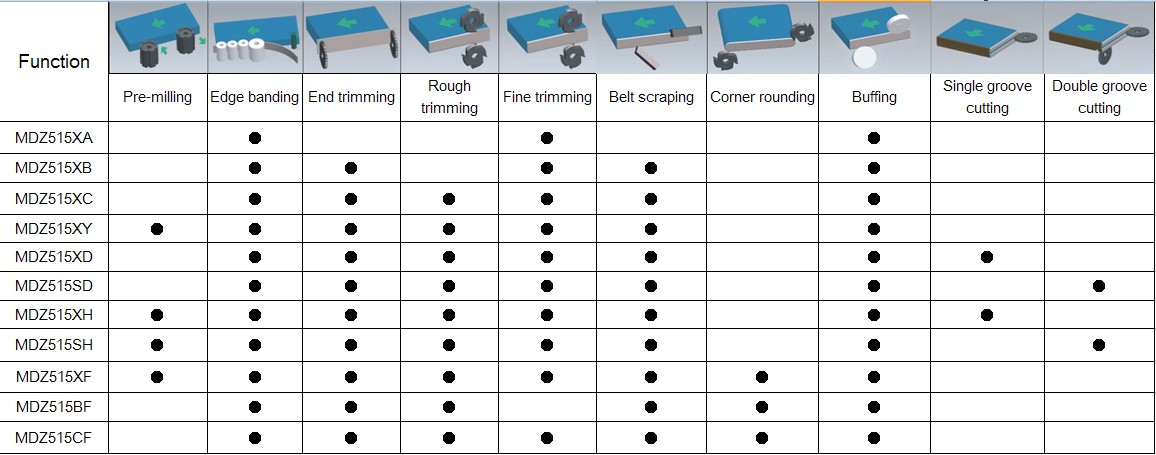

Main Functions of Automatic Straight Edge Banding Machine

Packing of Automatic Straight Edge Banding Machine

- Q: Custom wardrobe edge is not good, sunny taste is very heavy, I would like to use glass glue to wipe the corner of the side, do not know if it is feasible? The cabinet is a wall, knocking out the pity, have been more than a year, the winter is almost what have no taste, a sun is very smelly, but not pungent odor.

- It's better not to use glass glue. It's not finished and the time will not be long. I suggest you find some special glue for woodworking.

- Q: This is the following plate, do not want to use PVC or aluminum edge, too ugly, there is no paint or putty kind of things, can maintain wood color better?Ash integrated plate edge treatment, do not scratch putty directly do varnish okay?

- Mongolian pine Oh, Hei hei do not need to deal with it

- Q: The main reasons of edge banding degumming

- The main reasons are as follows:1, edge degumming is the main processor is too thin especially PVC edgebanding gum (agent) coating is too thin, and the decline of the hot melt adhesive affinity, which is one of the main reasons of the edge degumming.2, is the technical problem of edge machine temperature does not reach the predetermined temperature, causing sticking edge and hot melt adhesive glue is not good, the general requirements of the temperature at 180 ~ 210 degrees, can be adjusted according to the operating environment temperature sealing machine. This is mainly to look at the problem of technicians, manufacturers must strictly check, this is the problem of manufacturers.3, that is, the edge of the machine is too thin glue, originally did not produce a qualified edge banding. This is also an important reason, because the temperature and glue is too thin, causing the phenomenon of degumming is also common, you can increase the amount of glue to solve. The manufacturer's main problem is the manufacturer's responsibility. Everyone wants to think about it.4, uneven plate may also cause banding off, this is also must pay attention to the problem, appear this reason can only explain the installation technical problems.

- Q: Floor banding how to install, please expert pointing

- Edge banding is used in wood floor or around the edges and corners of the place, the use of conventional edge 45*45 of the wood edge thickness is 6mm; and 45*45 Aluminum Alloy edgebanding. Use 4*25 or 4*30 stainless steel self tapping screw, the distance between the screw and the screw is about 35cm. Edge banding, installation, splicing must also stay 5~6mm gap, corner corner of the best installation, so that both beautiful and difficult to deformation.Install sealing strip must be fixed screw before using a pistol drill guide eye, the size is larger than the lead screw diameter slightly smaller, in the edge on the eye, you must use the wind cone drill head and groove, so that the screw is screwed into the slot, so that the surface is flat.

- Q: How to solve the problem of sealing the package door?

- The door has been sealed, and it can not be processed when loading the door

- Q: How does Genesis seal edges and how to cheat scripts?

- It's not that simple

- Q: What is the cabinet edge?

- Is the cabinet door around four sides, mainly to see the door what material is the edge, general Aluminum Alloy is the most common, but this kind of easy sealing seam, long time will be difficult to take care of grease.Now here in Shanghai a little better cabinets, are sealing material and door panels are made of the same materials, such as paint door, the edge is together baking, so there is no gap, easy care, will not let the formaldehyde inside the cabinet door release.

- Q: The new home, four rooms are custom-made wardrobe, cabinets are MDF or particle board, and some wardrobe and wall joints with white glass adhesive edge, but there is no edge between the cabinet and the floor tiles.Some people say that white glass glue edge, wardrobe of the material is not waterproof, do not glue edge mopping the floor of the water will destroy the body, but the wardrobe from the bed are very close, and I worry that the bedroom is not good for too many people use glass glue, so have several teams of Henkel Black & Decker long-term mouldproof neuter glass glue and kitchen special transparent glass glue didn't keep.You have to move for a week. Is there any need to use it? Is there a one year old child who has a big influence on people right now? In the end is not good to use?

- NeedIf the floor is not sealed, the bottom of the cabinet is easy to enter the water and become moldy.It is easy to swell and mildew density board.And the general density board, wardrobe seal plate, the lower layer is not edge..

- Q: How to seal the edge of panel furniture?

- With manual curve edge machine ah, the new 5-6W or so, do the necessary machine board furniture ah. If your worker skill is good enough, you can completely seal yourself by hand. Use a hot blower over 1000 degrees. First, the edge banding will be glued on the edge sealing machine and then sealed.

- Q: How to install stainless steel edge banding?

- RBI glass adhesive

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East; Eastern Europe; South Asia. |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 500-700 People |

| Language Spoken: | Chinese; English |

| b) Factory Information | |

| Factory Size: | Above 800,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | Middle |

Send your message to us

Automatic Straight Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords