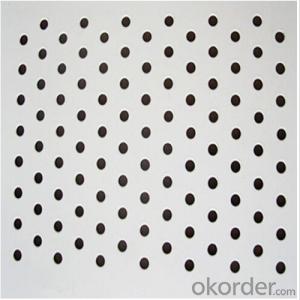

Perforated Aluminum Sheets for Decoration 1050, 1060, 1100, 3003, 5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets for Decoration Description:

Aluminum sheets are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm.

2.Main Features of Aluminum Sheets for Decoration:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

3. Aluminum Sheets for Decoration Images:

4. Aluminum Sheets for Decoration Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: This question asks for methods to verify the quality of aluminum sheets before purchasing them.

- <p>To ensure the quality of aluminum sheets, first, check for certifications such as ISO or ASTM standards. Inspect the surface for any defects like scratches, dents, or unevenness. The color should be uniform and the edges should be smooth. Request a sample and perform a bend test to check for flexibility and strength. Ensure the thickness is consistent as specified. Look for a reputable supplier with good customer reviews. Lastly, consider the price; if it's too low, it might indicate compromised quality.</p>

- Q: Can 101 aluminum sheets be used in HVAC systems?

- Yes, 101 aluminum sheets can be used in HVAC systems. Aluminum is commonly used in HVAC systems due to its excellent thermal conductivity, corrosion resistance, and lightweight properties. The 101 aluminum alloy is a commonly used grade that provides good strength and ductility, making it suitable for HVAC applications. It is often used for fabricating ducts, air handlers, heat exchangers, and other components in HVAC systems. Additionally, aluminum sheets are easy to work with and can be easily formed and shaped according to the specific requirements of the HVAC system.

- Q: What are the applications of aluminum sheets?

- The unique properties and versatility of aluminum sheets make them applicable in a wide range of industries. Some common uses for aluminum sheets include: 1. Construction: Aluminum sheets are utilized in various construction applications such as roofing, siding, gutters, and facades. They offer exceptional durability, resistance to corrosion, and the ability to withstand extreme weather conditions. 2. Transportation: The transportation industry extensively employs aluminum sheets, particularly in the manufacturing of automobiles, airplanes, trains, and ships. Their lightweight nature helps reduce fuel consumption, improve vehicle performance, and maintain strength and durability. 3. Packaging: Aluminum sheets are widely used in the food and beverage industry for packaging purposes. They are used in the production of cans, foils, and containers due to their ability to protect the contents from light, moisture, air, and bacteria. 4. Electronics: Aluminum sheets play a role in the production of electronic devices like laptops, smartphones, and tablets. Their excellent thermal conductivity properties make them ideal for heat dissipation, ensuring the longevity and performance of electronic components. 5. Industrial applications: Aluminum sheets find applications in various industrial sectors, including aerospace, marine, chemical, and energy. They are used to manufacture heat exchangers, tanks, pipes, and other equipment due to their corrosion resistance and high strength-to-weight ratio. 6. Decorative purposes: Aluminum sheets are also used for decorative purposes in architecture and interior design. They can be easily shaped, colored, and textured to create attractive facades, wall panels, ceilings, and furniture. 7. Reflective surfaces: Aluminum sheets are commonly employed for their reflective properties. They are used in mirrors, solar panels, light fixtures, and reflective signage to enhance brightness and improve energy efficiency. In conclusion, the exceptional properties of aluminum sheets make them widely applicable in various industries. Their lightweight nature, durability, resistance to corrosion, and thermal conductivity make them the preferred choice for construction, transportation, packaging, electronics, industrial applications, decoration, and reflective surfaces.

- Q: On the web page to see more information on the plating aluminum plate, I do not know what is the difference between aluminized and aluminum plating performance?

- Hot dip aluminizing applicationsAluminized steel is widely used. The type I aluminized steel plate, originally developed, is mainly used in automobile exhaust pipes and silencers. Type II is used mainly for roofing and side walls of buildings, as well as for chemical containers. The aluminized steel wire produced by the new process is expected to be used as the core of the transmission line instead of the galvanized steel wire. Aluminized steel pipe has been widely used in power plants, boilers, water wall tubes, steam pipes, heat exchangers and so on. Aluminized steel structure has been widely used in power transmission tower, told highway guardrail and so on.

- Q: only aluminum source i have is mountain dew cans any way to turn them quickly into a powder?or any other ideas?

- www.okorder sells both iron oxide and aluminum powder. Their CH0174 aluminum makes a great thermite. Way easier to just buy the stuff by the pound than than grinding aluminum cans or breaking apart etchasketches.

- Q: What is the minimum bending radius for aluminum sheets?

- The minimum bending radius for aluminum sheets depends on several factors, including the thickness and alloy of the sheet, as well as the bending method being used. However, as a general guideline, the minimum bending radius for aluminum sheets is typically around 1.5 to 2 times the thickness of the sheet. For example, if you have a 1mm thick aluminum sheet, the minimum bending radius would be around 1.5 to 2mm. It is important to note that these values can vary, so it is always recommended to consult the specific material and bending guidelines provided by the manufacturer or a professional in the field to ensure optimal results.

- Q: What are the different heat treatment options available for aluminum sheets?

- There are several heat treatment options available for aluminum sheets, each offering different properties and characteristics to the material. 1. Annealing: This process involves heating the aluminum sheet to a specific temperature and then slowly cooling it down. Annealing helps to relieve internal stresses in the material and improve its ductility and machinability. 2. Solution Heat Treatment: This treatment involves heating the aluminum sheet to a high temperature and then rapidly quenching it in water or other cooling media. Solution heat treatment is commonly used to dissolve and homogenize any alloying elements present in the aluminum, resulting in improved strength and hardness. 3. Precipitation Hardening: Also known as age hardening, this treatment is typically performed after solution heat treatment. It involves heating the aluminum sheet at a lower temperature for a specific period, allowing the alloying elements to precipitate and form fine particles. This process increases the strength and hardness of the aluminum without sacrificing its ductility. 4. Stress Relieving: This treatment is performed to relieve residual stresses that may have developed during fabrication or machining processes. The aluminum sheet is heated to a specific temperature and then slowly cooled down, reducing the risk of distortion or cracking. 5. Hardening: By heating the aluminum sheet to a specific temperature and then rapidly quenching it, hardening can be achieved. This process increases the strength and hardness of the material, making it more suitable for applications that require high strength-to-weight ratios. It is important to note that the specific heat treatment option chosen for aluminum sheets depends on the desired properties and application requirements. Consulting with a metallurgical expert or referring to the material's specifications can help determine the most suitable heat treatment option.

- Q: Can 101 aluminum sheets be used in the production of sporting goods?

- Yes, 101 aluminum sheets can be used in the production of sporting goods. Aluminum is a versatile material that offers several benefits for sporting equipment. It is lightweight, which is crucial for many sports equipment like bicycles, tennis rackets, and baseball bats, as it allows for easier handling and maneuverability. Additionally, aluminum is corrosion-resistant, ensuring the longevity of the sporting goods even when exposed to various weather conditions. It also provides excellent strength-to-weight ratio, making it suitable for high-performance equipment that requires durability without adding unnecessary weight. Therefore, 101 aluminum sheets can be a viable choice for manufacturing various sporting goods, providing the desired properties needed for performance, longevity, and user experience.

- Q: combines with oxygen with an atomic weight of 16, to form the compound aluminum oxide, how much oxygen would be required to react completely with 54g of aluminum?

- aluminum oxide is Al2O3 , or 2 part Al to 3 part O. 27 grams Al2 *2 / 54 grams Al available = 16 grams of O * 3 / X grams of O solve for X: X = 48 grams of oxygen needed next guy is right....the formula for aluminum oxide is Al2O3..sorry...I readjusted the formula above to show the change

- Q: What are the electrical conductivity properties of aluminum sheets?

- Aluminum sheets are equipped with exceptional electrical conductivity characteristics. With its low electrical resistance, aluminum finds extensive usage in diverse electrical applications. It boasts a high conductivity rating, marginally lower than that of copper, rendering it an effective electricity conductor. This attribute enables aluminum sheets to efficiently transmit electrical current with minimal energy wastage. Consequently, aluminum is extensively employed in power transmission lines, electrical wiring, and electrical connectors. Moreover, aluminum's conductivity renders it suitable for applications requiring heat dissipation, such as heat sinks in electronic devices. In general, aluminum sheets are renowned for their favorable electrical conductivity, making them a preferred choice in numerous electrical and electronic applications.

Send your message to us

Perforated Aluminum Sheets for Decoration 1050, 1060, 1100, 3003, 5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords