Adp Aluminum Coils - PE PVDF Marble Anodized Coat Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of PE PVDF Marble Anodized Coat Aluminum Coil

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of PE PVDF Marble Anodized Coat Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PE PVDF Marble Anodized Coat Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

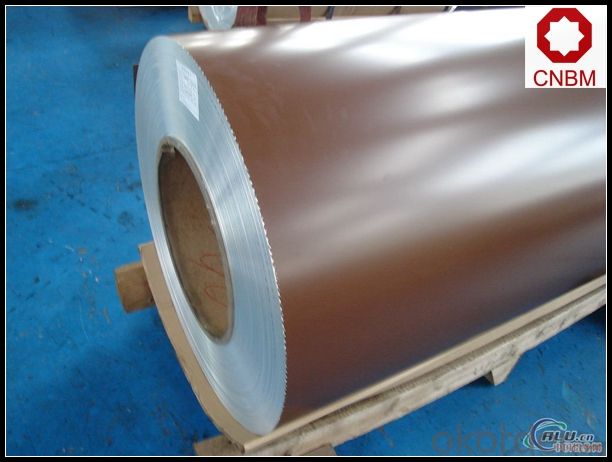

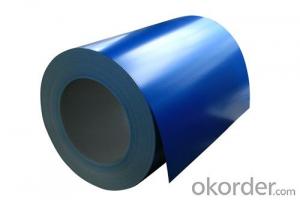

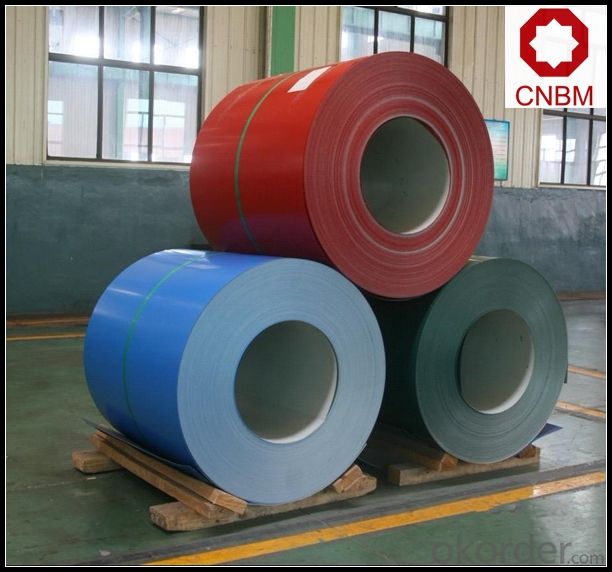

5. Image of PE PVDF Marble Anodized Coat Aluminum Coil

6. Package and shipping of PE PVDF Marble Anodized Coat Aluminum Coil

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in solar panel systems?

- Yes, aluminum coils can be used in solar panel systems. Aluminum is a popular material choice for solar panel frames and supports due to its lightweight yet strong nature. It is corrosion-resistant, durable, and has excellent thermal conductivity, making it suitable for withstanding harsh weather conditions and efficiently dissipating heat generated by the solar panels. Additionally, aluminum is also highly recyclable, which aligns with the sustainable nature of solar energy systems. Overall, the use of aluminum coils in solar panel systems contributes to their efficiency, longevity, and environmental friendliness.

- Q: Hi, I have a large bag of aluminium sulfate that I would like to use to turn my hydrangeas blue but there are no instructions on the pack, can anyone tell me how much I need (mixed with water)

- Si es tu profesora l. a. que te corrigio el blunders, sabe, quedate tranquila. El aluminio tiene número de oxidación +3 y el radical sulfato -2, intercambiando número de oxidación por atomicidad, para equilibrar, te queda lo que dijo tu profesora...

- Q: I would like to know why the ionic substance aluminium oxide doesn't dissolve in water.

- Aluminium gives away 3 electrons, and two aluminium atoms are combined with 3 oxygen atoms, the charge is just to great for it to gracefully dissolve.

- Q: Is it safe and effective to use aluminum coils for baking purposes?

- <p>Aluminum coils are generally not recommended for baking. While aluminum is a good conductor of heat and is used in some baking pans, using aluminum coils directly in baking can lead to uneven heating and potential health concerns due to the leaching of aluminum into the food. It's better to use materials specifically designed for baking, such as silicone or metal baking sheets, which are safe and provide even heat distribution.</p>

- Q: the ingredient on the back says aluminum?also ..what is sodium benzoate?Is all this stuff that terrible for you? Or does it mean something else?

- The aluminum is in the baking powder. Very common but you can buy it without it, it is much healthier for you. Aluminum is correlated to Alzheimer's and ADD. Baked goods taste much better without the aluminum too. Benzoate of soda, a preservative that can alter your DNA. Not too good for you, no matter what the FDA may say about it. All told, if you are concerned for your health, keep to organic as much as possible and made from scratch too. Way too much junk is put in our food and health products.

- Q: Can aluminum coils be used in high-altitude environments?

- Yes, aluminum coils can be used in high-altitude environments. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various applications, including in high-altitude environments. Aluminum coils are commonly used in air conditioning systems, heat exchangers, and refrigeration units, which can function efficiently at high altitudes. Aluminum's high strength-to-weight ratio allows it to withstand the extreme conditions found at high altitudes, including low temperatures, high winds, and low atmospheric pressure. Additionally, aluminum is non-magnetic, which is advantageous in certain high-altitude applications, such as aerospace and satellite technologies. Furthermore, aluminum has excellent thermal conductivity, allowing it to efficiently transfer heat, making it ideal for use in cooling systems operating in high-altitude environments. Its corrosion resistance properties also make it durable and able to withstand the effects of moisture, which can be prevalent in such environments. Overall, aluminum coils are a reliable and suitable choice for use in high-altitude environments due to their lightweight, corrosion resistance, thermal conductivity, and strength.

- Q: Do you think that stainless steel cookware with an aluminum core is safe? I am concerned about the links between aluminum and Alzheimers disease. Also, if anyone has heard of any health risks to using non-stick varieties of pans? I havent, but I would be curious to know if anyone else has.

- Aluminum cores are fine. They are wrapped in stainless (make sure), or stacked inside stainless steel. Aluminum is one of the most common elements in the world. We're exposed to it in more ways that you can count. Links to alzheimers are inconclusive. From what I understand, non-stick skillets are ok as long as you don't overheat them and cause the material to burn (you can smell the fumes when overheated). I use mine with medium heat, like for omelettes or grilled cheese sandwiches, but never for searing a steak.

- Q: My school has lunched catered in daily because it cuts down on staff in the kitchen. The food is delivered in individual aluminum containers for each student. In doing so, the school uses 99,000 aluminum trays in one school year, all of which get thrown away. I'm trying to find an alternative such as biodegradable food containers. Does anyone have any ideas? The container has to be able to withstand the heat of an oven.

- Maybe you could look into recyclable paper containers such as those that pizza places use? I'm always a big fan of materials like pyrex glass containers as they're reusable, strong, and can be returned to the company and sterilized.

- Q: Is it possible to utilize an aluminum coil for heating purposes?

- <p>Yes, aluminum coil can be used as a heater. Aluminum is a good conductor of heat, making it suitable for applications where heat transfer is necessary. However, it's important to note that aluminum has a lower melting point compared to other metals like copper or steel, so it's not ideal for high-temperature applications. Aluminum coils are commonly used in electric heaters, such as toasters and air heaters, where they can efficiently transfer heat to the surrounding air or materials. Always ensure that the aluminum coil is used within safe temperature limits to prevent damage or safety hazards.</p>

- Q: What are the different types of edge conditions for aluminum coils?

- There are several different types of edge conditions for aluminum coils, each serving a specific purpose and application. These edge conditions are designed to provide protection, enhance functionality, and ensure compatibility with various manufacturing processes. 1. Mill Edge: This is the standard edge condition produced during the initial rolling process at the mill. It is characterized by a smooth, straight, and burr-free edge. Mill edge coils are suitable for general applications and can be easily processed further. 2. Slit Edge: Slit edge coils are created by cutting the mill edge coils into narrower widths. This process removes a small strip of material along the edges, resulting in a slightly rougher edge compared to mill edge coils. Slit edge coils are commonly used in applications where precise width tolerances are required. 3. Trimmed Edge: Trimmed edge coils undergo further processing to remove irregularities or defects along the edges. This edge condition is achieved by shearing or trimming the coil to eliminate any imperfections. Trimmed edge coils are often used in applications that demand a high level of aesthetics or require a uniform appearance. 4. Deburred Edge: Deburring is a process that involves removing any sharp edges or burrs from the coil. This edge condition is achieved through mechanical or chemical methods, ensuring a smooth and safe edge. Deburred edge coils are commonly used in applications where safety is a concern, such as in the manufacturing of consumer goods. 5. Rounded Edge: Rounded edge coils have their edges rounded or softened to reduce the risk of injury during handling or installation. This edge condition is achieved through a variety of methods, including roll forming or edge rolling. Rounded edge coils are often used in applications where safety is paramount, such as in the construction industry. 6. Specialty Edge Conditions: In addition to the standard edge conditions mentioned above, there are also specialty edge conditions available for specific applications. These may include edge conditions designed for specific manufacturing processes like welding, bending, or forming. Specialty edge conditions are tailored to meet the unique requirements of certain industries or applications. It is important to select the appropriate edge condition for aluminum coils based on the specific requirements of the application. Factors such as aesthetics, functionality, safety, and manufacturing processes should all be considered when determining the most suitable edge condition.

Send your message to us

Adp Aluminum Coils - PE PVDF Marble Anodized Coat Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords