Wholesale Aluminum Coils - PE-PVDF Coated, Good Price, High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

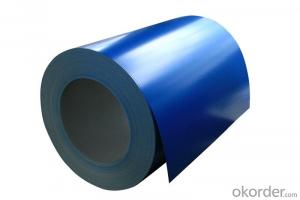

Structure of Aluminium Coated Coil Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

Advertisement: display platforms, signboards, fascia, shop fronts...

Main Features of the Aluminium Coated Coil:

Enviromental, light weight, waterproof, fireproof, anti-rust, weather resistance, easy cleaning, easy matching with other decoration materials...

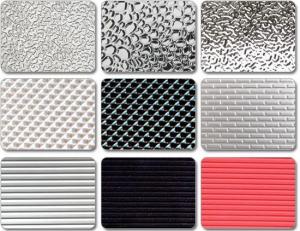

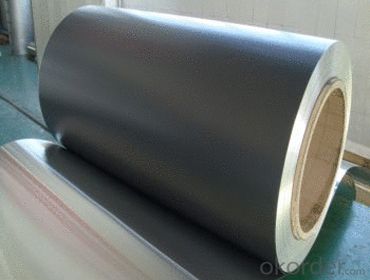

Images of Aluminium Coated Coil:

Aluminium Coated Specifications:

Grade | 1050,1060,1070, 1100, 1200, 2024,3003, 3004,3005, 3105, 5005,5052 5182,5754,8011 etc. |

Thickness | 0.1~1.6mm |

Width | 21~1600mm |

Application | Decorative Materials |

Surface Treatment | Coated |

Temper | O - H112 |

Hardness | More than 2H |

Yield (≥ MPa) | 160 |

Temper | O - H112 |

Ultimate Strength (≥ MPa) | 175 |

Elongation (≥ %) | 6 |

Packing material | Moisture-proof agent, steel tape bundle, wooden pallet, brown paper |

Method | Vertical( eye to sky) or horizontal( eye to wall) |

Standard spec | 1000mm xC, 1200mm xC etc |

Shipping | Container Loading or Bulk Pack |

FAQ of Aluminium Coated Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What happens when you mix Aluminum (or magnesium) with calcium carbonate? Can you write a chemical equation please?

- Neither aluminium nor magnesium will react with calcium carbonate. The suggested displacement reaction would only occur if aluminium or magnesium were more electropositive than calcium. Electrode potential data shows that this is not the case. Calcium is more electropositive than both aluminium and magnesium.

- Q: Can aluminum coils be used in low-friction applications?

- Low-friction applications can indeed make use of aluminum coils. Aluminum, being a lightweight and corrosion-resistant material, exhibits excellent thermal conductivity. These characteristics render it suitable for a variety of applications that prioritize low-friction. The automotive, aerospace, and HVAC industries often employ aluminum coils in heat exchangers, evaporators, condensers, and cooling coils. These coils are specifically designed to efficiently transfer heat while minimizing friction and energy loss. Furthermore, aluminum coils find utility in electrical motors, generators, and transformers, where smooth operation and reduced energy consumption are vital. Additionally, the lightweight nature of aluminum contributes to overall system weight reduction, thereby increasing efficiency. Moreover, various types of machinery and equipment that necessitate low friction, such as conveyor systems, sliding mechanisms, and bearings, can benefit from the utilization of aluminum coils. Aluminum's low coefficient of friction enables smooth and efficient movement, minimizing wear and tear on components. In conclusion, aluminum coils offer versatility in low-friction applications due to their lightweight, corrosion-resistant, and thermally conductive properties. Incorporating these coils can result in improved energy efficiency, reduced maintenance costs, and enhanced performance across a wide range of industries.

- Q: a) Although Aluminium is a reactive metal, it is used to make door frames and window frames.b) Although Aluminium conducts heat, it is used to make blankets, which are good thermal insulators.

- a) true b) false

- Q: The box doesn't tell me. I need to know because my gun range won't allow steel or aluminum cartridges

- You mean casings. You can tell as steel will have a coating of lacquer and aluminum will look like aluminum. The bullet itself will always be lead with a copper coat unless otherwise specified.

- Q: How are aluminum coils tested for surface roughness?

- Various methods are employed to test the surface roughness of aluminum coils, guaranteeing that they meet the necessary quality standards. One frequently utilized technique involves the utilization of a surface roughness tester or profilometer. This device gauges the roughness of the coil surface by tracing a stylus or probe across it and recording the height variations. The surface roughness tester furnishes data such as Ra (average roughness), Rz (average peak-to-valley roughness), and Rt (total height roughness). These parameters aid in evaluating the surface quality of the aluminum coil and ascertaining whether it adheres to the desired specifications. Additionally, visual inspection is commonly performed to identify any visible defects, scratches, or irregularities on the surface. This inspection can be carried out manually by trained operators or with the assistance of automated systems that employ cameras and image analysis algorithms to detect imperfections. Another method utilized to assess surface roughness involves the use of laser scanners. These scanners emit laser beams that bounce off the surface of the aluminum coil and are subsequently measured to determine the surface profile and roughness. Laser scanners offer high-resolution, contactless measurements, rendering them highly accurate and efficient for evaluating surface roughness. All in all, a combination of surface roughness testers, visual inspection, and laser scanners are typically employed to test the surface roughness of aluminum coils, guaranteeing that they meet the necessary quality standards for diverse applications.

- Q: like we have seen a disk of aluminum spinning, and a permanent magnet repell the plate because apparently because of temporary hystersis and because the north or south field causes the same in the aluminum, so why wont a plate of ruby do the same thing? Are not all metals, crystals? Perhaps its just too big and difficult a question for you simple huumans,..eh?

- A synthetic ruby may be made of aluminum, but that is not ALL that it is made of. The primary material in all rubies is aluminum oxide. So you need oxygen. It's not like the stuff is hard to find... they probably don't even need to overtly add it when they manufacture rubies. And of course, that creates a world of difference. Ferric oxide (a.k.a. rust) isn't magnetic either, even though iron is very strongly so. Aluminum is NOT naturally magnetic (though I'm sure it can be induced)... but if the parallel holds one might imagine that aluminum oxide would be just as nonmagnetic as ferric oxide, neh? As for metals being crystals... yes, that is so. But keep in mind also that just because all metals are crystals, it doesn't mean that all crystals are metals. Metals are (by definition) malleable, ductile, lustrous, and conductive. None of these things can be said of ALL crystals. Ruby may be a crystal, but it is not even vaguely a metal.

- Q: What is the maximum temperature that aluminum coils can withstand?

- The maximum temperature endurance of aluminum coils is determined by several factors, including the specific alloy composition, thickness, and application. In general, aluminum coils are renowned for their remarkable heat conductivity and ability to resist high temperatures. Frequently utilized aluminum alloys, such as 3003 or 5052, can endure temperatures of approximately 300-350 degrees Fahrenheit (150-175 degrees Celsius) without experiencing significant deformation or damage. Nevertheless, it is important to be aware that surpassing this temperature range can compromise the structural integrity of the aluminum coils, resulting in distortion, melting, or even combustion. Moreover, prolonged exposure to elevated temperatures can also diminish the overall strength and performance of the aluminum coils. Therefore, it is essential to refer to the manufacturer's specifications and guidelines for the specific aluminum alloy and application in question to ascertain the maximum safe temperature limit that the coils can withstand.

- Q: How do aluminum coils contribute to the electrical conductivity of products?

- Aluminum coils are widely used in electrical applications due to their excellent conductivity properties. The electrical conductivity of aluminum is high, making it an ideal material for transmitting and distributing electrical power. When aluminum coils are used in products, they facilitate the flow of electric current. Aluminum has a low resistance to the flow of electricity, allowing for efficient transmission of electrical energy. This low resistance ensures minimal power loss during transmission, which is critical in maintaining the efficiency of electrical systems. Additionally, aluminum coils have a high thermal conductivity, allowing them to quickly dissipate heat generated during the transmission of electrical current. This is crucial in preventing overheating and maintaining the stability and longevity of electrical products. The lightweight nature of aluminum also contributes to its suitability in electrical applications. Its low density makes it easier to handle and install, reducing the overall weight of products and making them more portable. Overall, aluminum coils play a significant role in enhancing the electrical conductivity of products. Their high conductivity, low resistance, and excellent thermal properties make them a preferred choice in a wide range of electrical applications, including power transmission lines, electrical cables, motors, transformers, and other electrical devices.

- Q: This question asks for methods to prevent rusting on aluminum coils during storage and transportation.

- <p>To prevent rusting on aluminum coils during storage and transportation, ensure that the coils are clean and dry before storage. Use a protective coating or wrapping to shield them from moisture and contaminants. Store the coils in a cool, dry place away from direct sunlight and corrosive substances. Avoid stacking them where they may come into contact with acidic materials. During transportation, secure the coils properly to prevent movement that could lead to scratches or damage. Use moisture-resistant covers to protect them from the elements. Regularly inspect the coils for signs of corrosion and address any issues promptly.</p>

- Q: How are aluminum coils manufactured to specific dimensions?

- Precision engineering and cutting-edge technology are utilized to manufacture aluminum coils with specific dimensions. The process commences with the selection of high-quality aluminum ingots, which are subsequently melted and cast into long, flat strips. Upon achieving the form of flat strips, the aluminum undergoes a sequence of rolling operations. The strips pass through a rolling mill, gradually decreasing in thickness and elongating in length. This rolling process is instrumental in attaining the desired dimensions and thickness for the coils. Following the initial rolling, the strips undergo annealing, a process involving heating the aluminum to a specific temperature and then cooling it slowly. This procedure enhances the ductility and reduces internal stresses in the metal, making it more manageable for subsequent manufacturing steps. The subsequent step is slitting, which involves cutting the wide strip into narrower strips of the desired width. High-precision slitting machines ensure accurate and consistent dimensions for each coil. Additionally, edge trimming is performed during the slitting process to eliminate irregularities and ensure straight edges. Once the narrower strips are obtained, specialized machines are utilized to coil them. These machines carefully wind the strips into coils of the desired size and shape, ensuring secure and tight winding. To further enhance dimensional accuracy, the coils may undergo a final leveling process. This process entails passing the coils through a machine that applies pressure to flatten any irregularities or distortions in the metal, ensuring a uniform and consistent thickness. In summary, the manufacturing of aluminum coils with specific dimensions necessitates a combination of precision rolling, slitting, coiling, and leveling processes. These processes, in conjunction with advanced machinery and quality control measures, guarantee that the final product meets the precise specifications required by the customer.

Send your message to us

Wholesale Aluminum Coils - PE-PVDF Coated, Good Price, High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords