Non Asbestos Fireproof Calcium Silicate Board Non Asbestos Fireproof Calcium Silicate Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

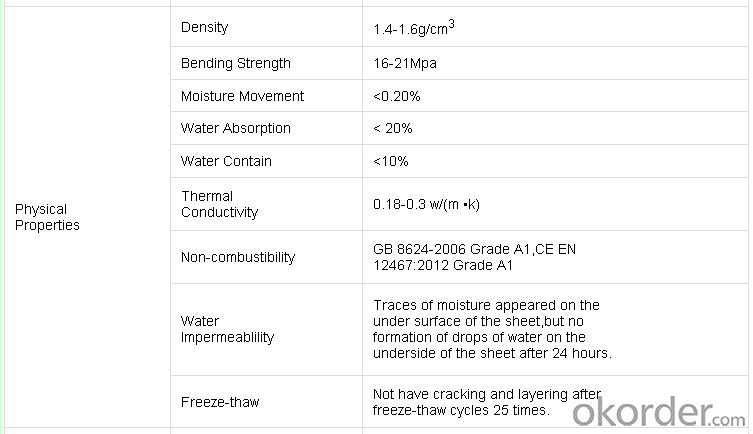

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

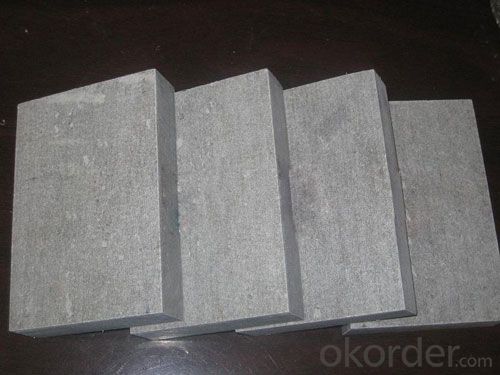

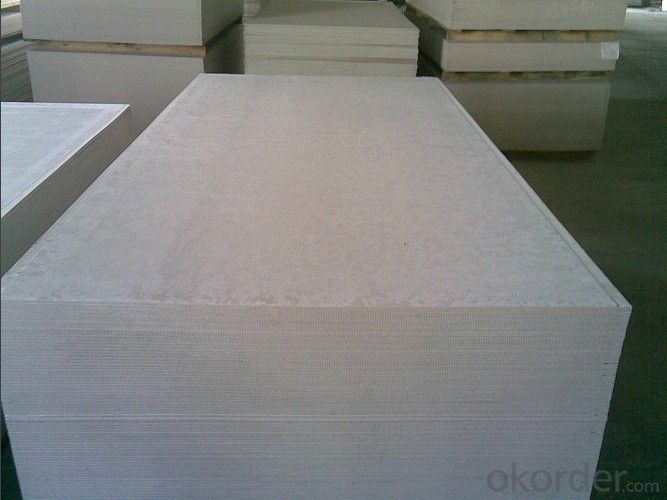

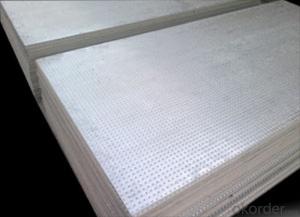

Images:

- Q: Is the cement board a cement pressure plate? What's the difference?

- Is a kind, just a different name

- Q: How to put tiles on the cement board

- 1, tiles to use cement, those bags to the construction team to do, to pay special attention, they are not responsible for maintenance, often shoddy, with poor quality cement, each bag can be less 5 yuan, they can earn more than 200 yuan The 2, in the smooth cement wall, the ground is calendering. In the shop before the wall and the ground should be hair. Can not put the brick directly on the wall paint above. 3, in the original tile on the floor of the new floor tiles, the original floor tiles must first knock down and then shop! Otherwise it is difficult to affix. 4, floor tiles often used dry shop, wall with wet shop. 5, with light steel keel, cement board bag riser, in the cement board on the tile, to hang wire mesh. Or easy to fall out.

- Q: Can tiles be attached to gypsum board?

- In the cut off the plate, can play a moisture-resistant role is the fiber cement board (Eide board). It is a fiber reinforced silicate plate, the main raw material is cement, plant fiber and minerals, by the high temperature autoclaved pressure, mainly used as building materials.

- Q: How do the fluorocarbon paint on the external wall of the cement pressure plate?

- Painting process: 1, spray epoxy seal primer A closed primer, the thickness of the count. The role is to close the water vapor, to prevent the back caused by the bubble, shedding and other lacquer. 2, putty leveling Epoxy putty or other flexible putty leveling. The effect is to obtain a sufficiently flat surface. To ensure the appearance of the formation, but also save the amount of paint. 3, spray paint Epoxy white coated with one or two. The role is to provide fullness of the paint, but also to provide the durability of paint, you can also save the amount of topcoat. 4, spray fluorocarbon paint Plain paint: finish or two.

- Q: Outdoor use of cement pressure plate can not

- Cement pressure plate, also known as fiber cement pressure plate or cement fiber pressure plate, is a natural fiber and cement as raw material, by the pulp, forming, cutting, pressing, curing a new type of building plate. Is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection features. It is based on siliceous and calcareous materials as the main substrate, with cellulose fiber reinforced materials, mixed with other auxiliary materials, through the copy forming, high pressure curing the formation of a new type of building materials.

- Q: Can you glue glue with glue?

- Polymer Agglomerate is the introduction of foreign advanced technology using imported raw materials to produce a polymer waterproof material. A variety of inorganic silicate as the substrate, the German imports of polymer polymer as an adhesive binder.

- Q: Bought new ceramic tile for kitchen and the old stuff is hard to get up. I want to keep the cement board that is in there for the new stuff.

- It's next to impossible to remove Ceramic with out damaging the cement board. Esp. if the tile was installed properly to begin with. Tile is installed with a thin-set type mortar when using a Cement backer. If installed over plywood they would have used a ceramic Mastic [glue] That can be removed much easier. You can however lay the new tile over the old, but this will raise the level of the floor, not a good idea when in the Kitchen.

- Q: I know cement board to cement board is taped with thinset and fibatape, but what about the seam at the sides that meet drywall? How should these be taped. What Materials should be used?

- I use a self adhesive fiberglass tape over that seam, and apply 90 minute joint compound over the tape. I assume you are bringing your tile to, or just over that edge anyway. I also assume that that particular joint will be outside the shower curtain or glass, whichever you will be using.

- Q: How much is the cement board?

- Good and bad can not say that you use there. It is in the construction and decoration are used on a wide range of .For example, the bathroom grid wall building exterior to do the shape. Fine decoration useful to make it decorative layer, the pursuit of some special The artistic effect.

- Q: Dry hanging cement fiberboard is not curtain wall

- Fibreboard with uniform material, vertical and horizontal strength difference is small, easy to crack, etc., widely used. Manufacture of 1 cubic meter of fiberboard about 2.5 to 3 cubic meters of wood, can replace 3 cubic meters of lumber or 5 cubic meters of logs. Development of fiberboard production is an effective way of comprehensive utilization of timber resources.

Send your message to us

Non Asbestos Fireproof Calcium Silicate Board Non Asbestos Fireproof Calcium Silicate Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords