Level A High Quality Mono Solar Cell 156mm with TUV,CE Certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 watt

- Supply Capability:

- 1000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details Of Mono Solar Cell 156mm

Specifications Of Mono Solar Cell 156mm

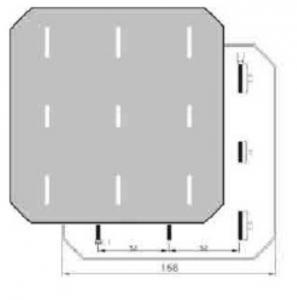

1.Mechanical data and design

Format | 156 mm × 156 mm ± 0.5 mm |

Thickness | - 210 μm ± 40 μm |

Front(-) | 1.5 mm bus bars (silver),blue anti-reflection coating (silicon nitride) |

Back (+) | 2.5 mm wide soldering pads (silver) back surface field (aluminium) |

2.Temperature Coefficient of Cells

Voc. Temp . coef.%/K | -0.35%/K |

Isc . Temp . coef.%/K | +0.024%/K |

Pm. Temp. coef.%/K | -0.47%/K |

3.Electrical Characteristic

Efficiency (%) | Pmpp (W) | Umpp (V) | Impp (A) | Uoc (V) | Isc (A) | FF (%) |

18.35 | 4.384 | 0.526 | 8.333 | 0.63 | 8.877 | 78.3% |

18.20 | 4.349 | 0.526 | 8.263 | 0.63 | 8.789 | 78.54% |

18.05 | 4.313 | 0.525 | 8.216 | 0.63 | 8.741 | 78.32% |

17.90 | 4.277 | 0.524 | 8.161 | 0.629 | 8.713 | 78.04% |

17.75 | 4.241 | 0.523 | 8.116 | 0.629 | 8.678 | 77.70% |

17.60 | 4.206 | 0.521 | 8.073 | 0.628 | 8.657 | 77.36% |

17.45 | 4.170 | 0.519 | 8.039 | 0.628 | 8.633 | 76.92% |

17.30 | 4.134 | 0.517 | 8.004 | 0.626 | 8.622 | 76.59% |

17.15 | 4.098 | 0.516 | 7.938 | 0.625 | 8.537 | 76.80% |

17.00 | 4.062 | 0.512 | 7.933 | 0.625 | 8.531 | 76.18% |

16.75 | 4.002 | 0.511 | 7.828 | 0.625 | 8.499 | 75.34% |

16.50 | 3.943 | 0.510 | 7.828 | 0.625 | 8.484 | 74.36% |

4.Intensity Dependence

Intensity [W/m2] | Isc× [mA] | Voc× [mV] |

1000 | 1.00 | 1.000 |

900 | 0.90 | 0.989 |

500 | 0.50 | 0.963 |

300 | 0.30 | 0.939 |

200 | 0.20 | 0.920 |

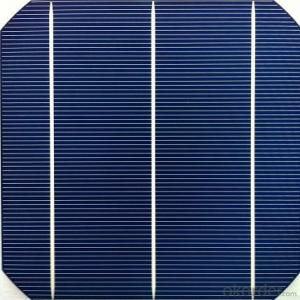

Advantage Of Mono Solar Cell 156mm

1: high quality cell, Level A cell

2: Dimensione:125*125mm Diagonal:150mm / 165mm

Dimensione:156*156mm Diagonal:200mm

3: Qualified certification: TUV,CE certification.

4: Warranty: five years for whole unit

Usage/Application Of Mono Solar Cell 156mm

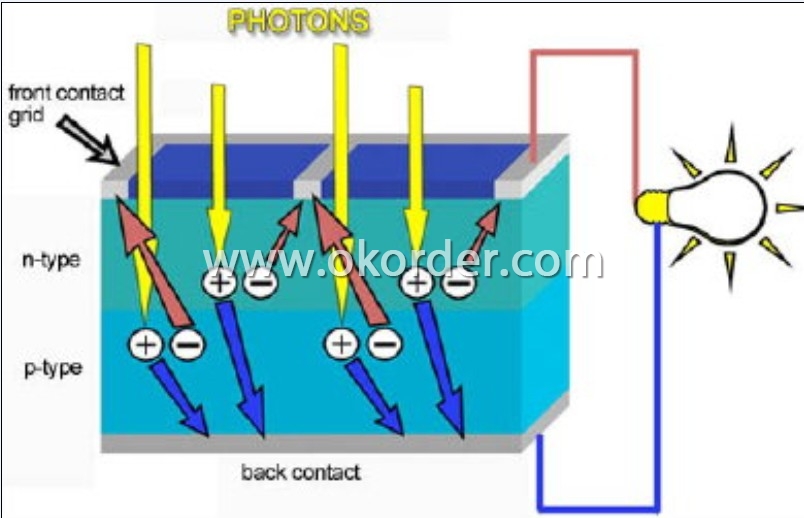

Monocrystalline solar cells are currently the fastest developing a solar cell, its structure and production process has been finalized, the products have been widely used for space and ground. Such solar cells with high purity silicon rods as raw materials. Silicon rods, material performance indicators in order to reduce production costs, and now solar terrestrial applications such as the use of solar grade somewhat relaxed. Some semiconductor devices can also be used for processing materials and discard the head and tail of silicon materials, solar cells after re-drawn into a dedicated silicon rods.

Packaging & Delivery Of Mono Solar Cell 156mm | |

Packaging Detai | Packaging Detail:Export Carton and Pallet or under customer request. |

Delivery Detail:10-20days | |

New Discovery of Solar Energy Material and Solar Cells

Nature prefers crystals. Salt, snowflakes, and quartz crystals are three typical examples, which is characterized by atoms and molecules are arranged in a unique lattice.

Industry also loves crystals. Electronic components is a crystal family, also known as semiconductors, the most famous is the silicon material.

In order to make semiconductor practical engineer must adjust its crystalline arrangement to control the start and stop the flow of electrons. Semiconducto r engineers need to know precisely the lattice energy of electrons required to move this energy value is called the energy gap. Similar to silicon, gallium arsenide and germanium and other semiconductor materials, they each have a unique energy gap of the crystal lattice. Through the determination of the energy gap, can determine what kind of material is suitable for electronic functions.

An interdisciplinary research team at Stanford University has successfully produced a semiconductor crystal with a variable energy gap. Such a semiconductor may be used as a solar cell, which is very sensitive to certain spectrum, from the sun to absorb more energy.

This raw material itself is not something new. Molybdenum disulfide (MoS2) is a crystalline rock, such as quartz, as a catalyst can be used to refine and lubricants.

Molybdenum disulfide is a single-layer structure: a triangular lattice of molybdenum atoms joins two sulfur. The nature of the rock is made up of many such single layer of material laminated together. Each has a single layer of molybdenum disulfide semiconductor potential applications.

Use of such a semiconductor material, we can get a great energy gap. This will have a beneficial aspect of the sensor, solar and other electronic applications.

Scientists have graphene endless praise. It found that graphene materials won the Nobel Prize, which is a single-layer structure consisting of a single layer of carbon atoms flat pendulum.

In 2012, the nuclear industry and MIT materials scientist devised a theory relates to semiconductor applications molybdenum disulfide monolayer. For any semiconductor, engineers must change its lattice arrangement so as to control the flow of electrons. For silicon, this adjustment comprises mixing a small amount of chemical substances in the crystal lattice.

Its scalability in the process is the most exciting thing. At the same time, from an industrial point of view, molybdenum disulfide very cheap.

- Q:What is a monocrystalline solar cell?

- A monocrystalline solar cell is a type of solar panel that is made from a single crystal structure, typically silicon. It is known for its high efficiency and sleek, black appearance. The single crystal structure allows for better electron flow, resulting in greater energy conversion from sunlight into electricity.

- Q:Can solar cells be used for refrigeration?

- Yes, solar cells can be used for refrigeration through the use of photovoltaic (PV) systems. These systems convert sunlight into electricity, which can then power refrigeration units. This allows for the generation of cold temperatures and preservation of perishable goods, making solar cells a viable option for refrigeration in areas without access to traditional power grids.

- Q:Can solar cells be used in data centers?

- Yes, solar cells can be used in data centers. They can help offset the energy consumption of the data center by generating clean and renewable electricity. However, their effectiveness may depend on factors such as the size of the data center, available space for solar panel installation, and the amount of sunlight available at the location.

- Q:What is the role of tracking systems in maximizing solar cell efficiency?

- Tracking systems play a crucial role in maximizing solar cell efficiency by continuously aligning solar panels with the sun's position throughout the day. This ensures that the panels receive maximum sunlight exposure, optimizing the conversion of solar energy into electricity. By tracking the sun's movement, these systems enable solar cells to operate at their peak efficiency, resulting in increased energy production and higher overall system performance.

- Q:How do solar cells handle electrical noise or interference?

- Solar cells do not directly handle electrical noise or interference. However, solar cell systems often include components such as inverters or power conditioning units that help mitigate electrical noise or interference by converting the direct current (DC) produced by the solar cells into alternating current (AC) that is more resistant to noise. Additionally, proper grounding and shielding techniques can be employed to minimize any potential interference from external sources.

- Q:What is the impact of wind on solar cell efficiency?

- The impact of wind on solar cell efficiency is generally minimal. While wind can cause slight vibrations or movements in solar panels, it does not significantly affect the overall efficiency of the cells. The main factors that influence solar cell efficiency are the angle and orientation of the panels towards the sun, as well as the amount of sunlight received.

- Q:How do solar cells perform in regions with high levels of air pollution?

- Solar cells perform less efficiently in regions with high levels of air pollution. Air pollution can block sunlight and reduce the amount of solar radiation reaching the solar cells, which in turn decreases their power output. Additionally, pollutants in the air can accumulate on the surface of solar panels, forming a layer of grime that further reduces their performance. Regular cleaning and maintenance of solar panels are necessary in such regions to ensure optimal functioning.

- Q:Can solar cells be used in electric vehicle charging stations?

- Yes, solar cells can definitely be used in electric vehicle charging stations. Solar panels can be installed on the roof or surrounding area of the charging station to harness sunlight and convert it into electricity. This renewable energy source can then be used to charge electric vehicles, making the charging process more sustainable and reducing dependence on the grid.

- Q:How do solar cells perform in regions with high levels of humidity and rainfall?

- Solar cells can still perform well in regions with high levels of humidity and rainfall. While humidity may slightly decrease the efficiency of solar cells, modern designs and materials are developed to withstand these conditions. Additionally, rainfall can actually be beneficial as it helps to clean the solar panels, removing dust and dirt that may accumulate on the surface. Overall, solar cells can still generate electricity effectively in regions with high humidity and rainfall, although their performance may be slightly affected.

- Q:What information can I get from the Internet about the solar cell modules? Such as what it is? How it is made?

- The solar cell module is composed of two loop circuits located respectively on two sides of the solar cell module, and converge respectively to the junction box.

1. Manufacturer Overview |

|

|---|---|

| Location | SanShui City, Guang Dong, China. |

| Year Established | 2009 |

| Annual Output Value | Above 10 billion RMB |

| Main Markets | Mid East;Western Europe;North America;Southeast Asia |

| Company Certifications | TUV ISO9001;SGS |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Zhuhai, Foshan |

| Export Percentage | 0.4 |

| No.of Employees in Trade Department | about 600 |

| Language Spoken: | English;Chinese; |

| b)Factory Information | |

| Factory Size: | 66666.7m2 |

| No. of Production Lines | 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | USD 0.3-0.45/Wp |

Send your message to us

Level A High Quality Mono Solar Cell 156mm with TUV,CE Certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 watt

- Supply Capability:

- 1000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords