Mobile Scaffolding Platform Formwork Scaffolding Connector with Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mobile Scaffolding Platform Formwork Scaffolding Connector with Great Price

Scaffolding Screw Jack Formwork Scaffolding China Low Price

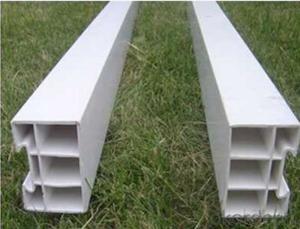

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

Scaffolding Screw Jack Formwork Scaffolding China Low Price

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Mobile Scaffolding Platform Formwork Scaffolding Connector with Great Price

Mobile Scaffolding Platform Formwork Scaffolding Connector with Great Price

Mobile Scaffolding Platform Formwork Scaffolding Connector with Great Price

- Q: Can steel frame formwork be used for both small-scale and large-scale construction projects?

- Yes, steel frame formwork can be used for both small-scale and large-scale construction projects. The steel frame provides stability and durability, making it suitable for various project sizes. Its versatility allows for easy customization and reusability, making it a cost-effective choice for construction projects of different scales.

- Q: How does steel frame formwork accommodate for different concrete reinforcement configurations?

- The versatility of the steel frame formwork system lies in its ability to easily adapt to various concrete reinforcement configurations. This is made possible through the incorporation of adjustable features and components. To begin with, the steel frames utilized in the formwork consist of modular panels that can be effortlessly assembled and disassembled. These panels possess the capability to be modified in terms of size and shape, thereby providing flexibility in accommodating different reinforcement configurations. The connection of these panels can be achieved using a variety of clamps or connectors, allowing for customization to match the specific reinforcement layout. Furthermore, the steel frames are equipped with adjustable struts or props that serve to support and stabilize the formwork. These struts can be conveniently extended or retracted to correspond with the height and depth of the reinforcement bars or mesh. This adaptability enables the formwork to be adjusted to the necessary dimensions, ensuring proper coverage and alignment of the reinforcement. In addition, the steel frames can incorporate adjustable brackets or holders that can be positioned at various points along the frame. These brackets serve the purpose of securing the reinforcement bars or mesh in place, preventing any displacement during the pouring of the concrete. The adjustability of these brackets allows for different reinforcement configurations, including varying bar sizes or spacing, to be accommodated. Overall, the steel frame formwork system offers exceptional adaptability to diverse concrete reinforcement configurations. Its modular design, adjustable panels, struts, and brackets enable it to be easily customized and tailored to suit the specific requirements of each project. This guarantees the proper reinforcement of the concrete structure, ensuring compliance with the specified design criteria.

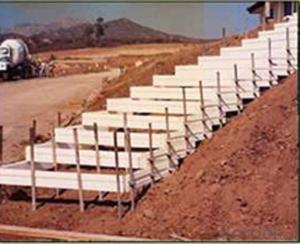

- Q: How does steel frame formwork support the construction of slabs and beams?

- Steel frame formwork supports the construction of slabs and beams by providing a stable and rigid structure to contain and shape the concrete during the pouring and curing process. Firstly, steel frame formwork is assembled according to the desired dimensions and layout of the slab or beam. The frames are typically made of sturdy steel sections that are bolted or welded together to create a strong and durable framework. This ensures that the formwork can withstand the pressure and weight of the concrete while maintaining its shape and position. Once the formwork is in place, it is carefully aligned and secured to the ground or supporting structure to prevent any movement or displacement during the pouring of the concrete. This is crucial to ensure that the slab or beam is constructed accurately and to the required specifications. Steel frame formwork also incorporates various support systems, such as adjustable props or scaffolding, to provide additional strength and stability. These supports help distribute the weight of the concrete evenly across the formwork, preventing any excessive load or stress on certain areas. This ensures that the slab or beam is uniformly reinforced and structurally sound. Furthermore, steel frame formwork allows for the creation of complex shapes and designs, including curved or inclined surfaces. The formwork can be easily adjusted or modified to accommodate different architectural requirements, allowing for flexibility and creativity in the construction process. Overall, steel frame formwork plays a crucial role in supporting the construction of slabs and beams by providing a robust and reliable structure to contain the concrete. It ensures accuracy, strength, and stability, ultimately contributing to the successful completion of a high-quality and safe construction project.

- Q: How does steel frame formwork contribute to the overall soundproofing of a structure?

- Steel frame formwork does not directly contribute to the overall soundproofing of a structure. The primary purpose of steel frame formwork is to provide temporary support and shape to the concrete during the construction process. However, it is important to note that soundproofing in a structure is typically achieved through the use of specific building materials and techniques. These techniques may include the use of insulation materials, such as acoustic foam or mineral wool, and the installation of soundproof windows and doors. While steel frame formwork does not directly contribute to soundproofing, it can indirectly influence the overall soundproofing of a structure. The construction process, including the installation of steel formwork, must be carried out with precision to ensure that there are no gaps or cracks that could potentially allow sound to pass through. By ensuring a tight and well-constructed concrete structure, the overall soundproofing of the building can be enhanced. Additionally, the use of steel frame formwork may also impact the overall weight and density of the structure, which can indirectly influence its soundproofing properties. A heavier and denser structure tends to provide better sound insulation. However, it's important to note that the impact of steel frame formwork on the weight and density of the structure may be relatively minimal compared to other factors such as wall construction materials and insulation. In summary, while steel frame formwork does not directly contribute to the overall soundproofing of a structure, it can indirectly influence the soundproofing by ensuring a well-constructed concrete structure and potentially impacting the weight and density of the building. However, achieving effective soundproofing requires the use of dedicated soundproofing materials and techniques specifically designed for that purpose.

- Q: Can steel frame formwork be used for precast concrete elements?

- Yes, steel frame formwork can be used for precast concrete elements. Steel frame formwork offers high strength, durability, and versatility, making it suitable for creating different shapes and sizes of precast concrete elements. Additionally, steel frame formwork provides excellent support and stability during the casting process, ensuring the accurate formation of precast concrete elements.

- Q: Does steel frame formwork require additional support during concrete pouring?

- Yes, steel frame formwork typically requires additional support during concrete pouring. This is because the weight and pressure exerted by the concrete can cause the formwork to buckle or collapse if not properly supported. Additional supports such as props, braces, or shores are used to provide stability and prevent any movement or deformation of the formwork system. These supports are strategically placed at regular intervals to distribute the load uniformly and ensure that the formwork remains in place throughout the pouring and curing process. By using additional support, the steel frame formwork can withstand the pressure and maintain its shape, resulting in a strong and durable concrete structure.

- Q: How does steel frame formwork contribute to faster construction times?

- Steel frame formwork contributes to faster construction times by providing a sturdy and reusable framework for pouring concrete. Its robust structure ensures quick and accurate assembly, allowing for efficient and precise concrete placement. Additionally, steel frame formwork can be easily adjusted and reused for multiple projects, reducing the need for frequent replacements and saving time on formwork preparation. The use of steel also minimizes the time required for formwork removal as it offers high strength and durability, enabling faster curing of concrete. Overall, steel frame formwork accelerates construction processes, leading to faster completion times.

- Q: How is the steel frame formwork secured to the ground?

- Securing the steel frame formwork to the ground involves various methods. Among them, ground anchors or stakes are commonly used. These anchors are driven into the ground and attached to the formwork, providing stability and preventing any shifting or movement during the concrete pouring and curing process. Furthermore, tie rods or braces can be utilized to further secure the formwork. These rods or braces connect the formwork to nearby structures or anchor points, ensuring its firm placement. The choice of securing method for the steel frame formwork depends on the project's requirements and the soil conditions at the construction site.

- Q: Can steel frame formwork be used for the construction of parking structures?

- Yes, steel frame formwork can be used for the construction of parking structures. Its strength and durability make it a suitable choice for supporting the weight and load of vehicles in a parking structure. Additionally, steel formwork offers flexibility in design and ease of assembly, allowing for efficient construction of parking decks and ramps.

- Q: Are there any specific design considerations for steel frame formwork?

- Yes, there are several specific design considerations for steel frame formwork. Firstly, the design should ensure that the steel frame is strong and rigid enough to support the weight of the concrete being poured. This involves determining the appropriate size and dimensions of the steel members, as well as the spacing and arrangement of the supports. Another important consideration is the ease of assembly and disassembly of the formwork. Steel frame formwork should be designed in a way that allows for quick and efficient installation and removal, as this can significantly impact the overall construction timeline and cost. Additionally, the design should take into account the potential for lateral forces, such as wind or concrete pressure, and ensure that the steel frame formwork is adequately braced and supported to resist these forces. This may include the use of diagonal bracing or tie rods to increase stability and prevent deformation of the formwork. The design should also address the issue of formwork deflection. Steel frames may have a tendency to deflect under the weight of the concrete, which can result in uneven surfaces or dimensional inaccuracies. To mitigate this, the formwork should be designed with sufficient stiffness and rigidity to minimize deflection and maintain the desired shape and dimensions of the concrete elements. Furthermore, the design should consider the reusability of the steel frame formwork. Steel is a durable material, and properly designed formwork can be used for multiple construction cycles, reducing waste and overall project costs. This requires attention to detail in terms of material selection, surface treatment, and overall durability of the formwork components. In summary, specific design considerations for steel frame formwork include strength and rigidity, ease of assembly and disassembly, resistance to lateral forces, prevention of formwork deflection, and reusability. A well-designed steel frame formwork system can contribute to efficient and cost-effective construction processes.

Send your message to us

Mobile Scaffolding Platform Formwork Scaffolding Connector with Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords