032 Aluminum Diamond Plate Sheets for Vessel Building - Mill Finished Aluminum Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

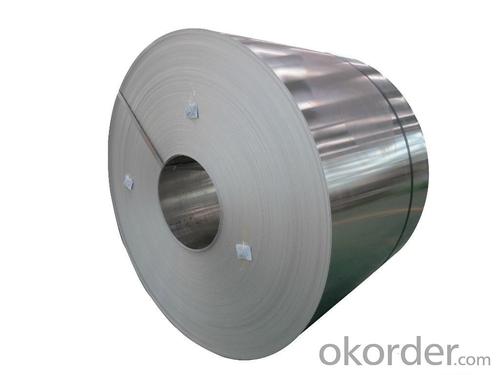

1.Structure of Mill Finished Aluminium Coils for Vessel Building

Mill Finished Aluminium Coils for Vessel Building is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Mill Finished Aluminium Coils for Vessel Building

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | TEMPER | THICKNESS | WIDTH | WEIGHT |

| AA1050 | H15 | 0.2MM-5MM | 1000MM-1500MM | 3TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheets be utilized as a material for constructing caravan roofs?

- <p>Yes, aluminum sheets can be used for caravan roofs. They are lightweight, durable, and resistant to corrosion, making them an ideal material for this purpose. Aluminum sheets are easy to install and maintain, and they can also reflect heat, helping to keep the interior of the caravan cooler. However, it's important to ensure that the aluminum sheets are of good quality and properly sealed to prevent water ingress and to maintain structural integrity over time.</p>

- Q: Is it possible to utilize aluminum sheets in the interior design of vehicles?

- <p>Yes, aluminum sheets can be used for car interiors. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications such as door panels, dashboards, and trim. Aluminum's malleability allows for easy shaping into complex designs, and it can be finished in various ways to match the aesthetic of the vehicle's interior. Additionally, its strength-to-weight ratio contributes to fuel efficiency and performance. However, it's important to consider the specific alloy and treatment of the aluminum to ensure it meets safety and comfort standards.</p>

- Q: 8mm which type of aluminum plate is suitable for bending?

- How do I calculate the pressure of the seamless steel tube with the outer diameter of 300mm and the thickness of 18mm L=600mm? material

- Q: Where does China make aluminum plate?

- In many parts of the country have aluminum factory, the old state-owned enterprises have 101, SWA aluminum plant, located in the southwest, northeast china. The emerging aluminum processing base in Henan, due to resource advantages, the largest aluminum factory, the price is relatively low.

- Q: Can aluminum sheets be used as a substitute for steel in certain applications?

- Yes, aluminum sheets can be used as a substitute for steel in certain applications. Aluminum is a lightweight and versatile material that offers several advantages over steel. It has a high strength-to-weight ratio, meaning it can provide the same strength as steel while being significantly lighter. This makes aluminum sheets an excellent choice for applications where weight reduction is critical, such as in aerospace, automotive, and transportation industries. Additionally, aluminum is highly resistant to corrosion, which eliminates the need for additional protective coatings or treatments. This property makes aluminum sheets suitable for applications in marine environments or other corrosive conditions. Aluminum sheets also exhibit excellent thermal conductivity, making them ideal for applications that require heat dissipation, such as heat exchangers or radiators. Furthermore, aluminum is more malleable than steel, allowing for easier shaping and forming. This characteristic makes aluminum sheets suitable for applications that require complex or intricate designs. However, it is important to note that aluminum has a lower tensile strength compared to steel. Therefore, in applications that require high load-bearing capacities or structural integrity, steel may still be the preferred choice. In such cases, a careful evaluation of the specific requirements and trade-offs between weight, strength, and cost should be considered before deciding on using aluminum sheets as a substitute for steel.

- Q: im wondering what happens if you MIG weld aluminum with the correct wire but without using a shielding gas? Would it just be extremely messy or does there HAVE to be an inert gas flowing for it to bond?thanks

- What is your machine that you will be using? Can you weld AC on it? Do you have a High Freq. Box? Will you GTAW it or use GMAW? What Alloy of Aluminum is it? Need much more info than you have provided. If GMAW best to have a pull or a push / pull wire feed system such as in a spool gun. Aluminum is too soft to just push from a wire feeder unit.

- Q: Which is better aluminum or stainless steel?

- They each have their own advantages and disadvantages. Which one is better depends entirely on what you're USING it for! -Aluminum has a better strength to weight ratio. In other words, while it is not as strong as steel, the fact that it weighs less than half as much makes up for it's lower strength. This is why most airplanes are made of aluminum. -Aluminum is generally more corrosion resistant than all but the most expensive stainless steels. However under certain condition it may corrode rapidly with catastrophic results. -Al is usually less expensive than stainless steel (SS), Though it is 2-4 times more expensive than ordinary (non-stainless) steels. -Al is fairly soft and easier to cut, saw, carve, drill, and machine than steels. (SS is very difficult to work with due to it's excellent abrasion resistance.) -Al is an excellent conductor of heat. This is why it's used for car radiators and air conditioning units, and for pots and pans. -Al is a very good conductor of electricity. Because of it's high conductance, light weight, and corrosion resistance, Al is used for high-voltage overhead power lines. -Stainless steel is stronger than Al, if weight is not a consideration. (In this respect, since Al is weaker, a pipe that could handle the same water pressure would need to be thicker if it was made of Al, So in many cases you can save money on materials by using SS) -SS is easy to weld. (welding Al is very difficult.) -SS can be used at much higher temps. than Al; which becomes very soft above about 400 degrees. -SS is more impact resistant than Al, in other words, it is more ductile. -SS is much more resistant to wear and abrasion, which as I said before makes it difficult to work with.

- Q: 1995 s10 I took this whole thing apart and marked and labled everything. Now i have an aluminum head sitting on a bucket that was spraying water right from the head gasket but the head gasket is in perfect shape, and there are no cracks i can see on the head. One more thing, the truck would not start up with water in it, but it would when it was drained, like it was blocking the spark or something. yes it did overheat has this ever happened to anyone else, and any ideas? Thank you.

- The parts are not straight. Check with an aluminum ruler in all directions.

- Q: How does the formability of aluminum sheet vary with different alloys?

- Variations in chemical composition and mechanical properties result in significant differences in the formability of aluminum sheet among different alloys. To enhance specific characteristics like strength, corrosion resistance, and formability, aluminum alloys are typically combined with elements such as copper, manganese, magnesium, and zinc. Aluminum alloys like the 1xxx series (pure aluminum) and the 3xxx series (manganese alloyed) are highly formable and commonly used for deep drawing applications. These alloys can be shaped into complex forms without cracking or tearing. In contrast, alloys with higher strength properties, such as the 2xxx series (copper alloyed) and the 7xxx series (zinc alloyed), generally have reduced formability. Although these alloys are often used in structural applications where strength is crucial, they require careful handling and processing to avoid defects during forming. Alloys in the 5xxx series (magnesium alloyed) offer a good balance of formability and strength. They are widely used in industries like automotive and aerospace, as they can be easily formed into different shapes while providing sufficient strength and corrosion resistance. It's important to note that the formability of aluminum sheet is not solely determined by the alloy composition. Other factors such as sheet thickness, forming temperature, and the specific forming process employed (e.g., deep drawing, bending, stretching) also influence formability. These factors interact with alloy properties to affect the formability characteristics of aluminum sheet. Therefore, careful selection of the appropriate alloy and process parameters is essential to achieve the desired formability for specific applications.

- Q: Are aluminum sheets suitable for high-temperature applications?

- Aluminum sheets are generally not suitable for high-temperature applications. While aluminum has a relatively high melting point of 660.3°C (1220.5°F), its strength and mechanical properties significantly decrease as the temperature rises. At elevated temperatures, aluminum tends to soften, deform, and lose its structural integrity. Additionally, aluminum has a relatively low thermal conductivity, which means it does not efficiently conduct heat away from the source, leading to potential overheating issues. Therefore, for high-temperature applications, materials such as stainless steel or refractory metals like titanium or tungsten are more commonly used due to their superior high-temperature performance and thermal conductivity.

Send your message to us

032 Aluminum Diamond Plate Sheets for Vessel Building - Mill Finished Aluminum Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords