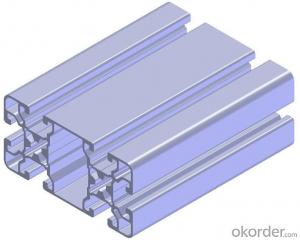

Mill Aluminum Extrusion Profiles Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Management Certification: ISO 9001:2008

Temper: O,F, H112,T4,T5,T6 and T8

Hardness: according to the alloy status

Specifications

1Aluminum alloy tube :AA3003/MOD/3005MOD/4343/7072/4104 etc

2,Temper: H14/24 etc.

3,For Radiator/Inter/oilcoolerEvaporator etc

1. Aluminum tube material for intercooler:

AA3003/3003+Zn/3003MOD/3004/3005/3005MOD/7072/4343/+zn/4045/+zn/4104/4004,etc

Per customer special requirement

Core alloy & Clad Alloy

3. Thickness Range:0.8mm≤T≤1.7MM (per customer special req.)

4.Width Range:10mm≤W≤1380mm

Product/Service (We Sell): | Aluminum coil, Aluminum foil, Aluminum plate non-cladded or cladded alloy) for

|

6. Packaging:

Per customer special requirement

Mark brazing side/non-braze side, water side

Clockwise /anticlockwise, eye to sky/eye to horizon

Cutting with paper core/aluminum core/steel core

Seaworthy Wooden Pallet standard; aluminum coils

- Q: Are aluminum profiles suitable for lighting fixtures?

- Yes, aluminum profiles are highly suitable for lighting fixtures. Aluminum is a versatile and lightweight material that offers several advantages for lighting applications. Firstly, aluminum profiles have excellent thermal conductivity, which means they effectively dissipate heat generated by the lighting fixtures. This is crucial as excessive heat can reduce the lifespan of the lighting components and affect their performance. Aluminum profiles help to maintain a cooler operating temperature, thereby enhancing the longevity and efficiency of the lighting fixtures. Secondly, aluminum profiles are corrosion-resistant, making them suitable for indoor and outdoor lighting fixtures. This resistance to corrosion ensures that the fixtures can withstand harsh environmental conditions, such as high humidity or exposure to moisture, without deteriorating or losing their functionality. Furthermore, aluminum profiles are easily customizable and can be designed to accommodate various lighting requirements. They can be extruded into different shapes and sizes, allowing for flexibility in the design of lighting fixtures. This versatility enables manufacturers to create sleek and modern lighting solutions that can be seamlessly integrated into different spaces and architectural designs. In addition, aluminum profiles offer aesthetic appeal as they can be powder-coated or anodized in various colors, providing a wide range of options to match different interior or exterior design themes. Lastly, aluminum is a sustainable material that is fully recyclable. Opting for aluminum profiles in lighting fixtures contributes to reducing environmental impact and supports the principles of sustainability. Overall, due to their thermal conductivity, corrosion resistance, versatility, aesthetic appeal, and sustainability, aluminum profiles are highly suitable for lighting fixtures and are widely used in the lighting industry.

- Q: Can aluminum profiles be used for industrial workbenches?

- Yes, aluminum profiles can be used for industrial workbenches. Aluminum is a lightweight and durable material that is commonly used in industrial applications. It offers excellent strength-to-weight ratio, corrosion resistance, and can be easily customized to suit specific needs. Additionally, aluminum profiles can be easily assembled and disassembled, allowing for flexibility and easy modifications to the workbench layout.

- Q: Can aluminum profiles be used in the production of audiovisual equipment?

- Aluminum profiles have the capability to be utilized in the manufacturing process of audiovisual equipment. Aluminum, a versatile material widely employed in various industries, including the audiovisual sector, can be employed in constructing frameworks, enclosures, and mounting systems for audiovisual equipment like speakers, projectors, and television screens. The lightweight characteristic of aluminum facilitates easy handling and transportation, while its high strength-to-weight ratio ensures lasting durability and stability. Furthermore, aluminum boasts corrosion resistance, a crucial attribute for equipment that may be exposed to moisture or humidity. Aluminum profiles can also be easily tailored and fabricated to satisfy specific design requirements, providing flexibility in audiovisual equipment production. In summary, the utilization of aluminum profiles in audiovisual equipment production presents numerous benefits in terms of strength, weight, corrosion resistance, and design possibilities.

- Q: Can aluminum profiles be used in marine environments?

- Yes, aluminum profiles can be used in marine environments. Aluminum is often chosen for its excellent corrosion resistance and lightweight properties, making it ideal for marine applications. It is commonly used in the construction of boats, shipbuilding, and offshore structures due to its durability and ability to withstand exposure to saltwater and harsh weather conditions.

- Q: What is aluminum profile?

- Aluminum bars: aluminum bars are obtained by hot extrusion and extrusion so as to obtain aluminum materials of different cross section. The production process of aluminum profile mainly includes three processes: casting, extrusion and coloring. Among them, the color mainly includes: oxidation, electrophoresis coating, fluorine carbon spraying, powder spraying, grain transfer and other processes. Aluminum profile features: 1) corrosion resistance; aluminum profile density is only 2.7g/cm3, about steel, copper or brass density (7.83g/, cm3, 8.93g/, cm3), 1/3. Aluminum can show excellent corrosion resistance in most ambient conditions, including air, water (or brine), petrochemical, and many chemical systems. 2) conductivity; aluminum profile is often chosen because of its excellent electrical conductivity. On the basis of equal weight, the conductivity of aluminum is nearly two times that of copper. 3) thermal conductivity; the thermal conductivity of aluminum alloy is about 50-60% of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, as well as the cylinder head and radiator of automobiles.

- Q: Are aluminum profiles suitable for use in architectural lighting fixtures?

- <p>Yes, aluminum profiles are commonly used for architectural lighting fixtures due to their durability, lightweight nature, and excellent heat dissipation properties. They offer design flexibility and can be easily shaped and machined to fit various lighting designs. Additionally, aluminum's resistance to corrosion makes it ideal for both indoor and outdoor lighting applications.</p>

- Q: How do aluminum profiles perform in terms of electrical conductivity?

- Aluminum profiles have relatively low electrical conductivity compared to other metals such as copper or silver. This is due to the fact that aluminum has a higher resistivity, meaning it offers more resistance to the flow of electric current. However, aluminum profiles still possess sufficient electrical conductivity for many applications. They can effectively conduct electricity, making them suitable for various electrical and electronic devices. Additionally, aluminum profiles can be specially treated or coated to enhance their conductivity if needed.

- Q: How do aluminum profiles perform in terms of creep resistance?

- Aluminum profiles generally exhibit good creep resistance. Creep is the tendency of a material to deform under constant load over time. Aluminum profiles tend to have a low creep rate compared to other materials, making them suitable for applications where long-term structural stability is required. The high strength-to-weight ratio of aluminum profiles also contributes to their creep resistance, as they can withstand heavy loads without significant deformation. However, it is important to note that the creep resistance of aluminum profiles can be influenced by various factors such as alloy composition, heat treatment, and operating conditions. Proper design and engineering considerations should be taken into account to ensure optimal creep performance in specific applications.

- Q: What are the different types of corner connectors used with aluminum profiles?

- There are several different types of corner connectors that are commonly used with aluminum profiles. These connectors are designed to join two or more aluminum profiles together at a corner, allowing for the creation of various structures such as frames, enclosures, and shelving units. One common type of corner connector is the 90-degree angle bracket. This type of connector features a right angle shape, with holes on each side to accommodate screws or bolts for fastening the profiles together. The 90-degree angle bracket is versatile and can be used for a wide range of applications. Another type of corner connector is the 45-degree angle bracket. This connector is similar to the 90-degree angle bracket but is designed to create a 45-degree angle joint between two profiles. It is commonly used in applications where a slanted or angled structure is desired. T-slot corner connectors are another popular choice. These connectors feature a T-shaped slot that allows for easy insertion of the profiles. They are typically used in applications where adjustability and flexibility are important, as they allow for easy repositioning and modification of the structure. Some corner connectors are designed specifically for certain types of profiles, such as the end cap connector. This type of connector is used to cap off the end of a profile, providing a finished look and protecting the profile from damage. In addition to these, there are various other corner connectors available, such as corner gussets, angle plates, and corner brackets. Each type of connector has its own unique features and advantages, making them suitable for different applications and requirements. Overall, the different types of corner connectors used with aluminum profiles provide a wide range of options for joining and assembling structures. These connectors offer strength, stability, and versatility, making them essential components in the construction of various aluminum profile-based projects.

- Q: Are aluminum profiles suitable for automotive racks and carriers?

- Yes, aluminum profiles are suitable for automotive racks and carriers. Aluminum is a lightweight and durable material that can withstand the demands of carrying heavy loads while maintaining structural integrity. It also has excellent corrosion resistance properties, making it ideal for outdoor use and exposure to different weather conditions. Additionally, aluminum profiles can be easily customized and designed to meet specific requirements, allowing for versatility in the design and construction of automotive racks and carriers.

Send your message to us

Mill Aluminum Extrusion Profiles Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords