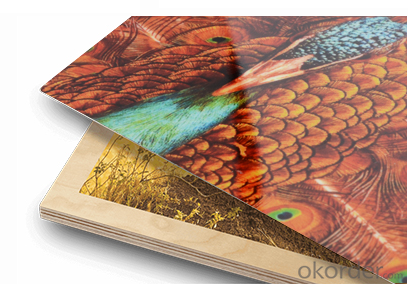

Corrugated Aluminum Sheets Price - Manufacturer Four Colors and Spot Color HD Metal Print

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

These Aluminum Panels can provide for many sizes and different color. It can suitable in many occasion, like company logo screen, show backdrop, home use, some gift use etc. We can also provide the heat press machine for transferring.

Features:

1. Extremely durable scratch resistant surface that is waterproof and can be cleaned easily with a damp cloth.

2. Eco-friendly & Terrific as a decoration.

3. Longest lasting photo medium in the current market.

4. The high definition, vibrant colors coupled with superior fade, moisture, stain & scratch resistant properties.

5. The image is infused into the coating to provide permanent protection and durability.

6. Excellent choice for commercial, fine art, and home decoration applications.

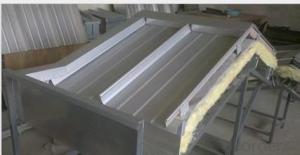

Making Process:

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top, pre-press for 60 sec., 180℃, 0.3Mpa.

4. 60 seconds later. Wait the panel to cool.

5. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

6. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

7. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

8. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.3Mpa.

9. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

10. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

11. Enjoy your personal designed aluminum board!

| Item# | Description | Size(in) | Size(mm) | Qty |

42030037 | Photo panel | 2" x 3" | 50.8x76.2 | 50 |

42030036 | Square photo panel | 4" x 4" | 101.6x101.6 | 10 |

42030012 | Photo panel | 4" x 6" | 101.6x152.4 | 10 |

42030032 | Square photo panel | 5" x 5" | 127x127 | 10 |

42030005 | Square photo panel | 6" x 6" | 152.4x152.4 | 10 |

42030004 | photo panel | 5" x 7" | 127x177.8 | 10 |

42030033 | Photo panel | 5" x 11" | 127x279.4 | 10 |

42030009 | Square photo panel | 8" x 8" | 203.2x203.2 | 10 |

42030013 | Photo panel | 5" x 10" | 127x254 | 10 |

42030038 | Photo panel | 8" x 10" | 203.2x254 | 10 |

42030034 | Photo panel | 5" x 17" | 127x431.8 | 10 |

42030024 | Photo panel | 8" x 12" | 203.2x304.8 | 10 |

42030010 | Square photo panel | 10" x 10" | 254x254 | 10 |

42030035 | Square photo panel | 11" x 11" | 279.4x279.4 | 10 |

42030003 | Square photo panel | 11.75"x 11.75" | 298.4x298.4 | 10 |

42030014 | Square photo panel | 12" x 12" | 304.8x304.8 | 10 |

42030031 | Photo panel | 11" x 17" | 279.4x431.8 | 10 |

42030006 | Photo panel | 9" x 21" | 228.6x533.4 | 10 |

42030015 | Photo panel | 10" x 20" | 254x508 | 10 |

42030042 | Photo panel | 11" x 14" | 279.4x355.6 | 10 |

42030025 | Photo panel | 12" x 18" | 304.8x457.2 | 10 |

42030028 | Square photo panel | 15" x 15" | 381x381 | 10 |

42030011 | Photo panel | 14" x 18" | 355.6x457.2 | 10 |

42030016 | Square photo panel | 16" x 16" | 406.4x406.4 | 10 |

42030017 | Photo panel | 12" x 24" | 304.8x609.6 | 10 |

42030002 | Photo panel | 15 "x 18.75" | 381x476.2 | 10 |

42030001 | Photo panel | 16" x 20" | 406.4x508 | 10 |

42030023 | Photo panel | 16" x 24" | 406.4x609.6 | 10 |

42030029 | Photo panel | 10" x 30" | 254x762 | 10 |

42030018 | Square photo panel | 20" x 20" | 508x508 | 10 |

42030019 | Photo panel | 20" x 24" | 508x609.6 | 10 |

42030020 | Square photo panel | 24" x 24" | 609.6x609.6 | 10 |

42030007 | Photo panel | 24" x 26" | 609.6x660.4 | 10 |

42030043 | Photo panel | 24" x 36" | 609.6x914.4 | 10 |

42030008 | Photo panel | 20" x 30" | 508x762 | 10 |

42030021 | Photo panel | 24" x 30" | 609.6x762 | 10 |

42030026 | Photo panel | 16" x 32" | 406.4x812.8 | 10 |

42030027 | Photo panel | 18" x 36" | 457.2x914.4 | 10 |

42030030 | Square photo panel | 30" x 30" | 762x762 | 10 |

42030022 | Photo panel | 30" x 40" | 762x1016 | 10 |

42030039 | Photo panel | 32" x 40" | 812.8*1016 | 9 |

42030040 | Square photo panel | 36" x 36" | 914.4x914.4 | 6 |

42030041 | Square photo panel | 48" x 48" | 1219.2x1219.2 | 6 |

- Q: This question asks for methods to verify the quality of aluminum sheets before purchasing them.

- <p>To ensure the quality of aluminum sheets, first, check for certifications such as ISO or ASTM standards. Inspect the surface for any defects like scratches, dents, or unevenness. The color should be uniform and the edges should be smooth. Request a sample and perform a bend test to check for flexibility and strength. Ensure the thickness is consistent as specified. Look for a reputable supplier with good customer reviews. Lastly, consider the price; if it's too low, it might indicate compromised quality.</p>

- Q: Are aluminum sheets suitable for HVAC ductwork?

- Yes, aluminum sheets are suitable for HVAC ductwork. Aluminum is a popular choice for ductwork due to its lightweight and durable nature. It is corrosion-resistant, which is important in HVAC systems where moisture and condensation can be present. Aluminum ductwork also offers good thermal conductivity, allowing for efficient heat transfer. Additionally, aluminum sheets are easy to work with, making installation and maintenance relatively simple. Overall, aluminum sheets are a reliable choice for HVAC ductwork, providing long-lasting performance and energy efficiency.

- Q: how many aluminum ions are present?how many chloride ions are present?what is the mass in grams of one molecule of aluminum chloride?help! i have no clue how to do this i need to know how for my quiz!!!

- You have to remember Avogadro's number: 6.02 x 10^23 Read about it in your text book. It is the number of molecules of any atom that make up 1 mole. 1 mole of a molecule is equal to it's atomic weight in grams. So, the atomic weight of aluminum is 26.9. So, 26.9 grams of aluminum contains exactly 6.02 x 10^23 molecules of aluminum (or 1 mole). What's the molecular weight of aluminum chloride? Well, 26.9 + 3(35.5) = 133.4 the 35.5 is the molecular weight of chloride and there are 3 of them. So, 133.4 grams of aluminum chloride would be 6.02 x 10^23 molecules. We only have 37.2 g. 37.2 g/ 133.4 g per mole = 0.279 moles. 0.279 moles x (6.02 x 10^23 molecules/mole) = 1.68 x 10^23 molecules of aluminum chloride. So, since there is one aluminum per molecule, you have your answer. Just multiply by three to find out how many molecules of chloride are present. Finally, if 133.4g = 6.02 x 10^23 molecules, then 1 molecule = 133.4 / 6.02x10^23 = 22.16 x 10^-23 or 2.216 x 10^-22 Make sure that the periodic table you use for class has the same values (some tables are more simplified then others). Also, make sure that you use the correct number of scientific digits when calculating your answer.

- Q: Can aluminum sheets be used in aerospace applications?

- Yes, aluminum sheets can be and are often used in aerospace applications. Aluminum is a popular choice for aerospace manufacturing due to its lightweight yet strong properties, making it suitable for various components such as structural parts, fuselage panels, and wings. Additionally, aluminum's corrosion resistance and ease of fabrication make it a versatile material for aerospace engineers.

- Q: 5083 what is the density of the aluminum plate?

- 5083 aluminum alloy is Al-Mg-Si, use a wide range, especially in the construction industry cannot do without this alloy, alloy is the most promising. The main alloying elements as magnesium, has good forming performance, corrosion resistance, weldability, moderate intensity, is a kind of pure aluminum alloy aluminum density: 2.71 tons. / m3 (g / cm3) alloy aluminum density: 2.8 tons / m3 (g / cm3) antirust aluminum density: 2.73 tons / m3 (g / cm3)

- Q: Can the aluminum sheets be used for manufacturing chemical storage tanks?

- Yes, aluminum sheets can be used for manufacturing chemical storage tanks. Aluminum is corrosion-resistant and has good strength-to-weight ratio, making it suitable for storing various chemicals safely.

- Q: What is the electrical conductivity of 101 aluminum sheets?

- The electrical conductivity of 101 aluminum sheets is high due to aluminum being a good conductor of electricity.

- Q: Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually part of the housing for my cell phone so doing it like this would probably not be right and the paint would probably wear out. I am mainly interested in finding out what kind of paint to use, what tools i need, and how to achieve an extremely! durable! matte finish because this phone is thrown around and going in and out of my pocket the paint will have to withstand getting rubbed down everyday by my pockets.That was a very long question, thanks for bearing with me and thanks in advance for those who provided me with an answer/thought. THANKS!

- Krylon is a very tough metal medium and the newer product they have at wal-mart in the paint section is fantastic. I don't know about rustoleum, other than another brand, but you could use a coat of polyutherine matte varnish. You can get this at wal-mart in the paint section or a hardware store. It will seal anything.

- Q: Can aluminum sheets be used for kitchen backsplashes?

- Yes, aluminum sheets can be used for kitchen backsplashes. Aluminum is a versatile and durable material that is commonly used for various applications, including backsplashes in kitchens. It offers several advantages such as being lightweight, corrosion-resistant, and easy to clean. Aluminum sheets can be easily cut and installed, making them a popular choice for modern kitchen designs. Additionally, they are available in a wide range of finishes and colors, allowing homeowners to find a style that complements their kitchen décor. Overall, aluminum sheets are an excellent option for kitchen backsplashes due to their practicality, aesthetic appeal, and ability to withstand the demands of a busy kitchen environment.

- Q: This question asks about the various types of adhesives that can be used to bond aluminum sheets together.

- <p>There are several types of adhesives suitable for bonding aluminum sheets together, including epoxy adhesives, which offer strong bonding and resistance to heat and chemicals; acrylic adhesives, known for their flexibility and resistance to UV light; cyanoacrylate adhesives, or super glues, which provide fast bonding but may not be as strong for heavy-duty applications; polyurethane adhesives, which are durable and flexible; and silicone adhesives, which are excellent for high-temperature applications and provide water resistance. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, temperature resistance, and curing time.</p>

Send your message to us

Corrugated Aluminum Sheets Price - Manufacturer Four Colors and Spot Color HD Metal Print

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords