Insulating Fire Brick - Lightweight Insulating Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

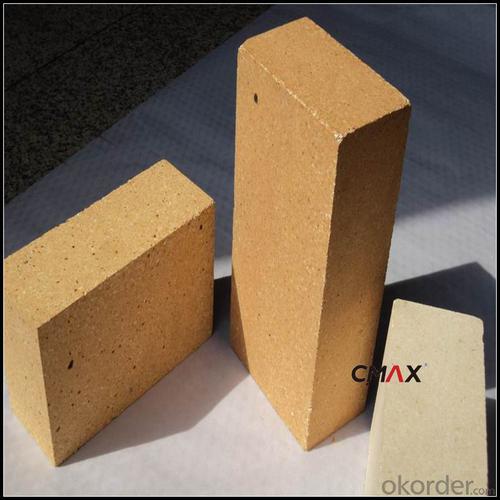

Light Weight Insulating Brick

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Light Weight Insulating Brick Features

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Light Weight Insulating Brick Application

Hot air duct ling

Shuttle kiln with high gas velocity

Laboratory furnace

Kiln car insulation

Light Weight Insulating Brick Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Are insulating fire bricks suitable for use in glass melting furnaces?

- Yes, insulating fire bricks are suitable for use in glass melting furnaces. Insulating fire bricks have high thermal resistance and low thermal conductivity, making them ideal for retaining heat and preventing heat loss in the furnace. Additionally, their lightweight and porous nature allow for efficient energy utilization and reduced fuel consumption.

- Q: Can insulating fire bricks be used for insulation in gas furnaces?

- Yes, insulating fire bricks can be used for insulation in gas furnaces. They are designed to withstand high temperatures and provide excellent insulation properties, making them suitable for use in gas furnaces to improve energy efficiency and enhance overall performance.

- Q: Are insulating fire bricks suitable for insulation in refinery heaters?

- Insulating fire bricks are indeed suitable for insulation in refinery heaters. These heaters operate at extremely high temperatures, and the insulating fire bricks are specifically designed to withstand these temperatures and provide efficient insulation. With their low thermal conductivity, these bricks effectively prevent heat from escaping the heater, thereby reducing energy loss and improving the overall efficiency of the heater. Moreover, these bricks possess exceptional thermal shock resistance, enabling them to endure sudden temperature changes without cracking or breaking. Given the frequent temperature fluctuations experienced by refinery heaters, this quality is essential. Furthermore, the lightweight nature and easy installation process of insulating fire bricks make them a convenient choice for insulation in refinery heaters. Ultimately, insulating fire bricks prove to be an appropriate and efficient option for insulation in refinery heaters.

- Q: Can insulating fire bricks be used in crucibles?

- Crucibles do not allow the use of insulating fire bricks. Insulating fire bricks are primarily meant for insulation purposes in kilns, furnaces, and fireplaces, where low thermal conductivity is desirable. On the other hand, crucibles necessitate materials with high thermal conductivity and resistance to endure the intense heat and chemical reactions involved in processes like metal melting or refining, conducting high-temperature experiments, or performing chemical reactions. Consequently, crucibles are generally constructed using materials like graphite, clay, or ceramic, which can withstand the extreme conditions and facilitate efficient heat transfer.

- Q: Can insulating fire bricks be used in the construction of ceramic fiber kilns?

- Yes, insulating fire bricks can be used in the construction of ceramic fiber kilns. Insulating fire bricks provide excellent thermal insulation, which helps to retain heat and improve energy efficiency in kilns. They are often used as the lining material in kilns to prevent heat loss and ensure efficient firing processes.

- Q: What are insulation bricks for? Do not use high-rise buildings on the ah?

- Heat preservation bricks are of course used for insulation... Tall buildings should not be used

- Q: Can insulating fire bricks be used in the construction of gas kilns?

- Yes, insulating fire bricks can be used in the construction of gas kilns. Insulating fire bricks are designed to have low thermal conductivity, which means they can help retain heat and improve energy efficiency in a kiln. Gas kilns require proper insulation to ensure that heat is evenly distributed and maintained within the kiln chamber. Insulating fire bricks can be used to line the walls, floor, and ceiling of the kiln, creating a barrier that helps to prevent heat loss and improve the kiln's performance. Additionally, insulating fire bricks are lightweight and easy to work with, making them a popular choice for kiln construction projects.

- Q: Can insulating fire bricks be used for insulation in smelters?

- Indeed, insulation in smelters can be achieved by utilizing insulating fire bricks. These bricks are purposefully crafted to endure elevated temperatures and offer exceptional thermal insulation. Composed of lightweight refractory materials with low thermal conductivity, they effectively retain heat and limit heat dissipation. As a result, they prove to be a perfect choice for smelters, where maintaining optimal temperatures is imperative for efficient metal smelting operations. Furthermore, insulating fire bricks possess resistance against chemical corrosion and mechanical strain, guaranteeing their longevity and appropriateness for use in demanding smelting settings.

- Q: Are insulating fire bricks resistant to phosphoric acid?

- Insulating fire bricks are generally not resistant to phosphoric acid. Phosphoric acid is a strong acid that can react with and corrode many materials, including fire bricks. While some fire bricks may have a certain level of resistance to acidic environments, it is unlikely that insulating fire bricks would be able to withstand prolonged exposure to phosphoric acid without significant deterioration. It is therefore recommended to use acid-resistant materials, such as acid-resistant bricks or linings, when dealing with phosphoric acid or other strong acids.

- Q: Can insulating fire bricks be used for insulation in furnaces?

- Yes, insulating fire bricks can be used for insulation in furnaces. Insulating fire bricks are made from lightweight materials such as clay and minerals, which have excellent thermal insulation properties. They are designed to withstand high temperatures, making them suitable for use in furnaces. These bricks help to reduce heat loss and improve energy efficiency by preventing the escape of heat from the furnace. Additionally, insulating fire bricks can also help to protect the outer structure of the furnace from excessive heat, thereby extending its lifespan. Overall, insulating fire bricks are a reliable and effective choice for insulation in furnaces.

Send your message to us

Insulating Fire Brick - Lightweight Insulating Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords