Jacketed Beer Bright Tank Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

Processing: Storage Tank, cutting-rolling-welding-polishing-assembling-testing-warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: bright tank, KB-006

Processing Types: Alcohol

Voltage: 380V, 50HZ

Certification: B&V; CE

Image:

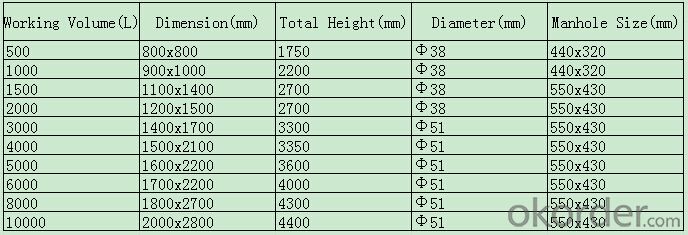

Specifications

1.manhole 2.CIP spraying ball 3.adjusting feet 4.sample valve 5.temperature gauge 6.pressure gauge 7.level gauge

Technical Data:

- Q: How do Boiler Systems work?

- Go okorder and type in boiler. You'll see a long article with pictures that explains. I think the best article you may want to read there is called something like how to troubleshoot a boiler.

- Q: I currently have a 10 year old boiler for an older home that is running fine and gets an annual cleaning every year. The home has had upgrades like a new roof, new windows, added insulation, and new fiberglass doors over the years and I am trying to decide if I should save and wait for next year to upgrade the boiler or if I should just drop the money on a new pellet stove for the ground floor. PS - I currently have a pellet stove in the basement and it works great.

- I would try to figure what the cost is for operating the boiler each year, include the annual cleaning in the operating costs. Then figure the cost to buy and operate the pellet stove instead. Take the cost of purchasing the pellet stove and divide it by how long it is expected to last before it needs to be replaced. Add that number to the annual cost of pellets and cleaning or whatever maintenance the pellet stove requires each year. Then compare the annual cost of operating the boiler, which is paid off already for the purposes of this analysis, and the cost to operate the pellet stove, including the amortized cost to buy and install it. Since you said the boiler is running fine, I assume you expect the pellet stove to be cheaper to operate each year. how long have pellets been available? Are the sales of pellet stoves increasing, decreasing or staying about flat each year? If sales are decreasing, you may find pellets go up in price, since there are fewer people to share the overhead of making pellets at all. You get the idea, you need to figure out how fast you start to save money with the pellets and how risky the money saving proposition is at all. Then add a third option, which is a new boiler that is presumably more efficient? Do the amortization of the purchase price, including installation, the same way you did the pellet stove to get an annual cost figure to compare to the other two. If the 10 year old boiler is near the end of its useful life, then you can disregard the first option, just keeping it and running it til it drops.

- Q: Related to commercial building inspections.

- They can blow up if the pressure in the boiler gets to high. They can release very hot water or very hot steam. They are normaly found in large commercial building or industrial plants.

- Q: What is the role of sodium chloride in the boiler

- Scale heat conduction capacity is relatively poor, it hinders the heat to the hot water conduction, increased energy consumption.

- Q: does anyone know how much a bryant bw9 boiler costs w/install?

- The boiler would be between $3,500.00 - $4000.00, usually 8 hrs labor - $500 - $700.00 plus what ever materials are needed say $500.00 - $1000.00 so a total of $4700.00 - $5700.00

- Q: I have a Vokera combi boiler (excell SP 80) which is probably around 12 years old. Lately is has switched off for no apparent reason. Even though I have managed to switch it back on, what would you recommend to do : have it repaired or changed?Other question, when I asked for quotes to have it changed, the plumber told me that the gas pipe is too narrow and the gas pipes leading to the boiler need to be changed. This would entail major work, so my question is : shy should I have wider gas pipes fitted?Thanks in advance for all your answers

- Newer boiler would be more efficient. I would get another bid though. wider gas lines? That sounds fishy. The gas supply line should be fine unless you increase the BTU's . But even then it should be fine.

- Q: my landlord opened up the ceiling in the hall outside my apartment to work on the electrical wiring. it has been a month now, and no one has closed up the ceiling yet, so all the wiring is exposed. the gas boiler is in very close proximity to the wires. is this a hazard?

- To even ask that question means it's worth fixing. Better safe than sorry.

- Q: The cause of the boiler

- Boiler to the outsourcing of residual oil, cracking residual oil and pumping more than C4 fuel, their components are heavier, high viscosity, low self-ignition point, when burning carbon, steam fog fuel when the broken capacity is also poor, large

- Q: Boiler flue gas treatment

- Measures to control the discharge of these substances are pre-combustion treatment, improved combustion technology, dust removal, desulfurization and denitrification.

- Q: We have a Worchester Bosch boiler in our house, but we haven't topped it up since 2 and a half years. I want to know how often do we need to top it up. We don't use central heating, all we use is hot water. Also, our pressure gauge is on 1. Is that alright? If we need to top it up, I don't know how to do it, as I don't have the manual. Could someone who has a similar boiler tell me how to top up the boiler please? It would be appreciated.

- A boiler is not something for an inexperienced person to try to perform maintenance on. you should ask for friends and neighbors if they know someone who could take a look at it.

Send your message to us

Jacketed Beer Bright Tank Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords