High Quality Insulating Fire Brick GJM23-26 Insulation Bricks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Insulation Brick:

CMAX insulating firebricks are classified under temperature between 1100℃ to 1700℃, manufactured from high purity alumina clay..

2.Main features of Insulation Brick:

◆Light weight and low thermal conductivity ◆Low heat storage

◆Low iron and impurities ◆High thermal shock resistance

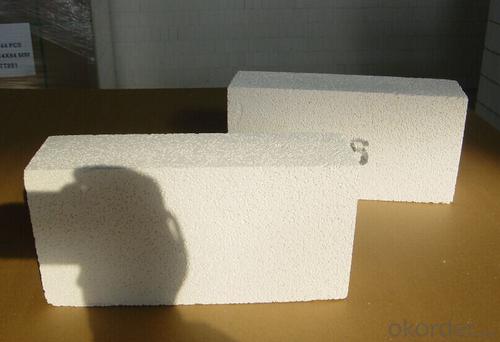

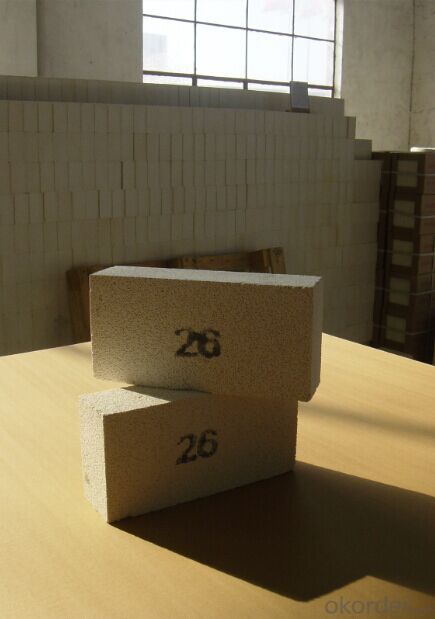

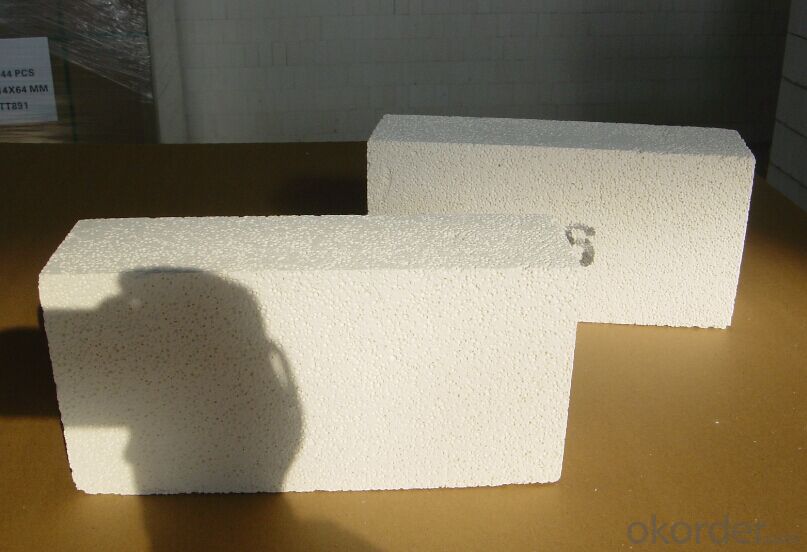

3. Insulation Brick Images:

4. Insulation Brick Technical Parameters

Our Insulation Brick contains 20, 23, 25,26, 28, 30, 32. Classification temperature is from 1100℃ to 1760℃. Density is from 0.52g/cm3 to 1.25g/cm3. As we all know, the company type is 23 and 26.

1) For the 23, its density is 0.52g/cm3, but some customer may require 0.8g/cm3, we can also meet your special require. Content of Al2O3 is about 45%.

2) For the 26, its density is 0.8g/cm3, but if you have other special requirement on that, pls also tell us. Content of Al2O3 is about 55%.

Application: CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our Insulation Brick?

A world class manufacturer & supplier of InsulationBrick is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do insulating fire bricks affect the overall energy consumption of a structure?

- A structure's overall energy consumption can be greatly reduced by the use of insulating fire bricks. These specialized bricks are designed to have low thermal conductivity, effectively preventing heat transfer. Installing them in the walls, floors, and roofs of a building significantly minimizes heat loss or gain through these surfaces. One major advantage of insulating fire bricks is their ability to improve a structure's thermal insulation. Heat naturally moves from hotter to cooler areas, causing buildings to experience heat loss in cold winters and heat gain in hot summers. By acting as a barrier, insulating fire bricks limit the transfer of heat through the building envelope. This insulation helps maintain a stable indoor temperature and reduces the need for excessive heating or cooling, resulting in lower energy consumption. Moreover, these bricks also enhance the overall energy efficiency of a structure by optimizing the performance of heating and cooling systems. Since they minimize heat transfer, the heating system can operate more efficiently without compensating for heat loss. Similarly, air conditioning systems can effectively cool the building with reduced heat gain. This efficient operation of HVAC systems leads to lower energy consumption and decreased energy demand for the structure. Additionally, insulating fire bricks contribute to the sustainability of a structure by reducing its carbon footprint. With reduced energy consumption, these bricks help lessen the environmental impact associated with the building. The decreased energy usage benefits not only the environment but also the occupants, as it results in lower utility bills and makes the structure more cost-effective in the long term. In conclusion, insulating fire bricks have a significant impact on a structure's overall energy consumption. Their excellent thermal insulation properties minimize heat loss or gain, improve the efficiency of heating and cooling systems, and contribute to the sustainability of the structure. Incorporating these bricks into the construction or renovation process effectively reduces energy consumption, resulting in a more energy-efficient and environmentally friendly building.

- Q: Can insulating fire bricks be used in outdoor fire pits?

- Yes, insulating fire bricks can be used in outdoor fire pits. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for outdoor fire pits where heat retention and durability are important.

- Q: Are insulating fire bricks resistant to oil and gas?

- Insulating fire bricks are generally resistant to oil and gas. These bricks are made from high temperature materials such as alumina and silica, which provide excellent thermal insulation properties and can withstand high temperatures. They are commonly used in industries where there is exposure to heat, such as in furnaces, kilns, and fireplaces. However, it is important to note that the resistance to oil and gas can vary depending on the specific composition and manufacturing process of the insulating fire bricks. Some bricks may have a higher resistance to oil and gas compared to others. To ensure the best resistance to oil and gas, it is recommended to use insulating fire bricks that are specifically designed for such applications. These bricks are often referred to as oil and gas resistant fire bricks and are manufactured with additional additives or coatings that enhance their resistance to these substances. In summary, while insulating fire bricks are generally resistant to oil and gas, it is advisable to use bricks that are specifically designed for such applications to ensure optimal performance and longevity.

- Q: Are insulating fire bricks resistant to sound transmission?

- Yes, insulating fire bricks are known to have good sound insulation properties and are resistant to sound transmission.

- Q: Can insulating fire bricks be used in the construction of heat shields?

- Certainly, heat shields can indeed be constructed using insulating fire bricks. These bricks are specifically designed to withstand elevated temperatures and possess exceptional thermal insulation properties. Their ability to effectively absorb and distribute heat makes them an ideal choice for the creation of heat shields, which serve to safeguard against excessive heat and mitigate thermal damage. In industries that involve high temperatures, such as steel, glass, and ceramics, insulating fire bricks are frequently employed. Moreover, their lightweight nature and ease of handling make them a practical option for constructing portable or easily installable heat shields. In summary, insulating fire bricks are a reliable and appropriate material for constructing heat shields in a diverse range of applications.

- Q: What are the types of building blocks?

- Ordinary housing: building brick (clay brick), and non sintered brick (sand lime brick, fly ash brick, cement brick, etc.)

- Q: Can insulating fire bricks be used as a backup insulation material?

- Yes, insulating fire bricks can be used as a backup insulation material. Insulating fire bricks are designed to have a high thermal resistance and low thermal conductivity, making them suitable for providing insulation in high-temperature applications. They can be used as backup insulation behind other refractory materials to enhance insulation properties and improve the overall thermal efficiency of a system.

- Q: What are the sizes of lightweight thermal insulation bricks?

- The production of material ordinary lightweight insulating refractory brick with fireclay and high alumina high strength bead brick

- Q: How thick should the insulation layer be when using insulating fire bricks?

- The thickness of the insulation layer when utilizing insulating fire bricks relies on several factors, including the desired level of insulation, the surrounding environment's temperature, and the insulation's specific application or purpose. Generally, insulating fire bricks are engineered to deliver exceptional thermal insulation, effectively reducing heat transfer. However, the thickness of the insulation layer should be determined according to the project's specific requirements. For applications requiring high-temperature insulation, it is typically recommended to use a thicker layer of insulating fire bricks. This is because a thicker layer can provide superior insulation and more effectively minimize heat loss. Furthermore, a thicker insulation layer can enhance the overall structural integrity of the insulation system. Conversely, in cases where lower temperature insulation is necessary or when there are space limitations, a thinner layer of insulating fire bricks may suffice. It is essential to consider the thermal conductivity properties of the insulating fire bricks being utilized and ensure that the desired insulation requirements are met. It is important to note that insulation standards may differ based on local building codes, safety regulations, and industry norms. Therefore, it is advisable to seek guidance from professionals or experts in the field to determine the optimal thickness of the insulation layer when using insulating fire bricks for a specific project.

- Q: Can insulating fire bricks be cut or shaped to fit specific applications?

- Yes, insulating fire bricks can be cut or shaped to fit specific applications. They are often made of soft and porous materials, such as ceramic fiber or lightweight refractory materials, which can be easily cut using common tools like saws or knives. This flexibility allows for customization and fitting into various shapes and sizes to meet specific requirements in different applications.

Send your message to us

High Quality Insulating Fire Brick GJM23-26 Insulation Bricks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords