Insulating Fire Brick GJM23 - High-Performance Insulation Range

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Firebricks

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature of Insulating Firebricks

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

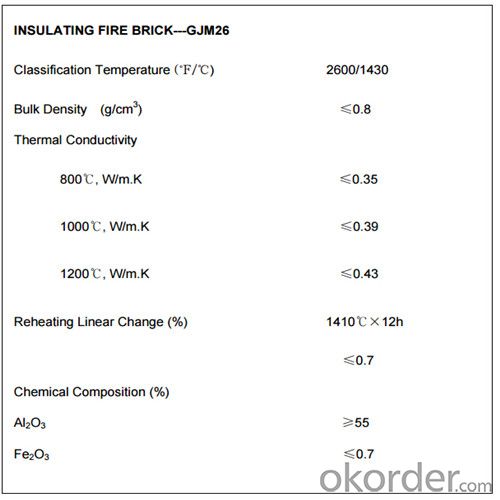

Technical Data of Insulating Fire Brick

What are the excellent features of Insulating Fire Brick?

High heat resistance and durability

Excellent insulating properties

Excellent resistance to thermal shock

Low thermal conductivity

Low heat storage

Excellent construction/compressive strength

Particularly suited to highest temperature applications above 1600°C or 2800°F

Structural integrity capable of dealing with erosive and abrasive environments

Low impurity

Precise dimensions

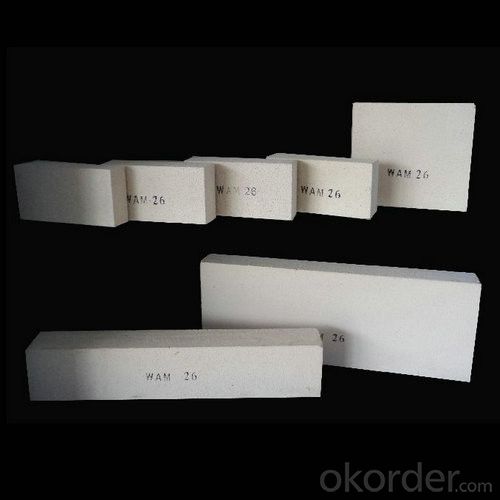

Image of Insulating Fire Brick

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Are insulating fire bricks resistant to abrasion or erosion?

- Yes, insulating fire bricks are resistant to both abrasion and erosion.

- Q: Can insulating fire bricks be used for insulation in gas furnaces?

- Yes, insulating fire bricks can be used for insulation in gas furnaces. Insulating fire bricks are made from lightweight materials such as clay and other minerals, which have excellent insulating properties. They are designed to withstand high temperatures and are commonly used in industrial applications, including gas furnaces. These bricks help to minimize heat loss, improve energy efficiency, and maintain high temperatures within the furnace. Additionally, insulating fire bricks are resistant to thermal shock and can withstand the corrosive effects of gases and chemicals present in gas furnaces. Therefore, they are a suitable choice for insulation in gas furnaces.

- Q: Can insulating fire bricks be used in the construction of flue gas ducts?

- Yes, insulating fire bricks can be used in the construction of flue gas ducts. These bricks are designed to withstand high temperatures and have excellent insulation properties, making them suitable for lining flue gas ducts where heat retention and energy efficiency are important.

- Q: Can insulating fire bricks be used for insulation in heat treatment furnaces?

- Yes, insulating fire bricks can be used for insulation in heat treatment furnaces. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They have low thermal conductivity and can effectively retain heat within the furnace. Additionally, their lightweight nature makes them easy to handle and install. Insulating fire bricks are commonly used in various heat treatment applications, such as annealing, tempering, and hardening processes, to ensure optimal heat retention and energy efficiency in the furnace.

- Q: Are insulating fire bricks resistant to alkali-silica reaction?

- Yes, insulating fire bricks are generally resistant to alkali-silica reaction due to their low alkaline content and high silica content.

- Q: Are insulating fire bricks resistant to acids and alkalis?

- Insulating fire bricks are generally resistant to acids and alkalis, but the level of resistance can vary depending on the specific composition and manufacturing process of the bricks. Insulating fire bricks are typically made from materials such as alumina, silica, or a combination of both, which provide excellent resistance to high temperatures and thermal conductivity. These materials are generally chemically inert, meaning they do not react with acids or alkalis. However, it is important to note that some acids and alkalis can still cause slight degradation or corrosion over time, especially if they are highly concentrated or used at elevated temperatures. In such cases, it is advisable to consult the manufacturer's specifications or conduct specific tests to determine the level of resistance of the insulating fire bricks to the particular acids or alkalis in question. Overall, insulating fire bricks are a suitable choice for applications that involve exposure to acids and alkalis, but it is always recommended to consider the specific requirements and consult with experts or manufacturers to ensure the bricks will perform adequately in the intended environment.

- Q: Can insulating fire bricks be used in kiln car construction?

- Yes, insulating fire bricks can be used in kiln car construction. Insulating fire bricks are made from lightweight materials that have excellent insulating properties, such as ceramic fibers or lightweight refractory aggregates. These bricks have low thermal conductivity, which means they can effectively retain heat and prevent heat transfer to the outer surface of the kiln car. Using insulating fire bricks in kiln car construction offers several benefits. Firstly, it helps to reduce heat loss, which improves energy efficiency and lowers fuel consumption. This is particularly important in high-temperature applications like kilns, where maintaining a consistent temperature is crucial. Secondly, insulating fire bricks can help to protect the kiln car from thermal stresses and cracking. Kilns undergo significant temperature changes during firing cycles, and the use of insulating fire bricks can help to minimize thermal shock and extend the lifespan of the kiln car. Furthermore, insulating fire bricks are lightweight compared to traditional refractory bricks, making them easier to handle and install in kiln car construction. This can lead to cost savings in terms of labor and transportation. However, it's important to note that insulating fire bricks have lower strength and durability compared to dense refractory bricks. Therefore, they are typically used in the hot face lining of kilns, while a more robust material is used for the kiln car structure. In conclusion, insulating fire bricks can be effectively used in kiln car construction to improve energy efficiency, protect against thermal stresses, and enhance the overall performance of the kiln.

- Q: Are insulating fire bricks suitable for use in thermal power plants?

- Yes, insulating fire bricks are suitable for use in thermal power plants. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in areas where heat needs to be contained, such as furnaces, boilers, and other thermal power plant equipment. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking.

- Q: Can insulating fire bricks be used in crucibles?

- Crucibles do not allow the use of insulating fire bricks. Insulating fire bricks are primarily meant for insulation purposes in kilns, furnaces, and fireplaces, where low thermal conductivity is desirable. On the other hand, crucibles necessitate materials with high thermal conductivity and resistance to endure the intense heat and chemical reactions involved in processes like metal melting or refining, conducting high-temperature experiments, or performing chemical reactions. Consequently, crucibles are generally constructed using materials like graphite, clay, or ceramic, which can withstand the extreme conditions and facilitate efficient heat transfer.

- Q: Can insulating fire bricks be used in high-temperature insulation applications?

- Indeed, high-temperature insulation applications can employ insulating fire bricks. These bricks are specifically engineered to endure and preserve heat in elevated temperatures. With their low thermal conductivity and exceptional insulation capabilities, they prove to be the perfect choice for containing and insulating high temperatures. Their widespread usage can be observed in industries like steel, glass, and ceramics, as well as in furnaces, kilns, and other equipment operating at extreme temperatures. By effectively retaining heat and minimizing energy loss, insulating fire bricks offer a dependable and efficient insulation solution for high-temperature environments.

Send your message to us

Insulating Fire Brick GJM23 - High-Performance Insulation Range

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords