Insulating Fire Brick - Insulation Brick, Insulating Brick, GJM23, GJM26, GJM28, GJM30, GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Fire Brick GJM23

Insulating fire bricks GJM23 are made from high purity alumina and low iron content raw materials. The insulating fire bricks are produced by mixing, casting or extruding, drying, sintering and grinding. Our insulating fire bricks GJM23 temperature is 1260℃(2300℉). A variety of type could be done according to customer’s request.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM23,we choose the casting methord.The casting insulating fire bricks offering the lowest density, the lowest thermal conductivity for the application above 1000℃.

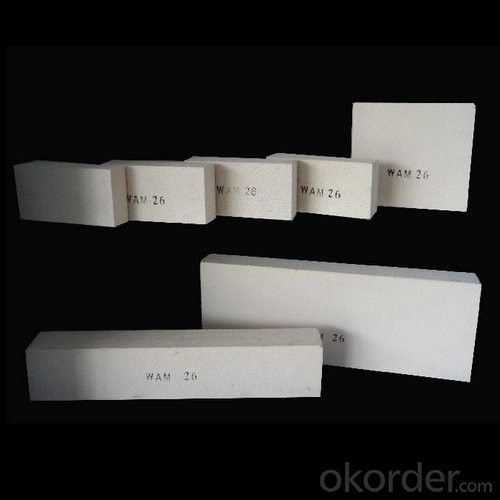

General Information of Insulating Fire Brick GJM26

Insulating fire brick GJM26 are produced by mixing, casting or extruding, drying, sintering and grinding. Our insulating fire bricks GJM23 temperature is 1430℃(2600℉). We could supply a wide range of shapes.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM26,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

General Information of Insulating Fire Brick GJM28

Insulating fire brick GJM28 are produced by high purity alumina and low iron raw materials. A viariety of shapes are available.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM28,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

General Information of Insulating Fire Brick GJM30

Insulating fire brick GJM30 are produced by mixing, casting or extruding, drying, sintering and grinding. Our insulating fire bricks GJM30 temperature is 1430℃(2600℉). We could supply a wide range of shapes.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM30,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

Typical Application of Insulating Fire Brick

Typical applications of magnesia bricks include ferroalloy furnace, metal mixer, Non-metallurgy industry furnace, high temperature kiln, calcined lime furnace, regenerator in glass furnace.

Technical Data of Insulating Fire Brick

| JM23 | JM26 | JM28 | JM30 | JM32 | ||||

| Physical Properties: | ||||||||

| Classifiction Temperature | ℃ | 1260.0 | 1430.0 | 1500.0 | 1600.0 | 1650 | ||

| Density | Kg/m3 | 550.0 | 850.0 | 900.0 | 1000.0 | 1100 | ||

| Cold Crushing Strength | Mpa | 1.2 | 2.0 | 2.5 | 2.8 | 3.5 | ||

| Reheating Linear Change(24hrs) | ||||||||

| 1230℃ | % | 0.4 | ||||||

| 1300℃ | ||||||||

| 1400℃ | % | 0.5 | ||||||

| 1510℃ | % | 0.6 | ||||||

| 1600℃ | % | 0.7 | ||||||

| 1650℃ | % | 0.8 | ||||||

| Hot Load Strength Deform(90 minutes) | ||||||||

| 1100℃ at 0.034 Mpa(5psi) | % | 0.1 | ||||||

| 1260℃ at 0.069 Mpa(10psi) | % | 0.2 | ||||||

| 1320℃ at 0.069 Mpa(10psi) | % | 0.3 | ||||||

| 1370℃ at 0.069 Mpa(10psi) | % | 0.2 | 0.1 | |||||

| Thermal Conductivity | ||||||||

| 400℃ | W/m.k | 0.2 | 0.3 | 0.3 | 0.3 | 0.32 | ||

| 600℃ | W/m.k | 0.2 | 0.3 | 0.3 | 0.3 | 0.35 | ||

| 800℃ | W/m.k | 0.2 | 0.3 | 0.4 | 0.4 | 0.38 | ||

| 1000℃ | W/m.k | 0.2 | 0.3 | 0.4 | 0.4 | 0.42 | ||

| 1200℃ | W/m.k | 0.4 | 0.4 | 0.4 | 0.44 | |||

| 1400℃ | W/m.k | |||||||

| Specific Heat | KJ/Kg.K | 1.1 | 1.1 | 1.1 | 1.1 | 1.10 | ||

| Chemical Analysis: | ||||||||

| Al2O3 | % | 47.0 | 50.0 | 60.0 | 70.0 | 75.0 | ||

| SiO2 | % | 44.4 | 47.1 | 38.2 | 28.3 | 23.2 | ||

| Fe2O3 | % | 0.9 | 0.7 | 0.6 | 0.5 | 0.5 | ||

| TiO2 | % | 1.2 | 0.1 | 0.1 | 0.1 | 0.1 | ||

| CaO | % | 5.2 | 0.1 | 0.1 | 0.1 | 0.1 | ||

| MgO | % | 0.3 | 0.2 | 0.1 | 0.1 | 0.1 | ||

| Na2O+K2O | % | 1.1 | 1.7 | 0.8 | 0.7 | 0.6 | ||

Photo of Insulating Fire Brick

- Q: Can insulating fire bricks be used in chimney construction?

- Yes, insulating fire bricks can be used in chimney construction. These bricks have high heat resistance and low thermal conductivity, making them suitable for lining chimneys and other high-temperature applications. They help to insulate the chimney and prevent excessive heat transfer, reducing the risk of structural damage and improving energy efficiency.

- Q: How do insulating fire bricks help improve the efficiency of heat treatment processes?

- Insulating fire bricks help improve the efficiency of heat treatment processes by effectively reducing heat loss. Due to their low thermal conductivity, these bricks act as a barrier, preventing heat from escaping and maintaining high temperatures for longer periods. This allows the heat treatment process to be more energy-efficient, as less energy is required to achieve and maintain the desired temperatures. Additionally, insulating fire bricks help to evenly distribute heat, resulting in more consistent and uniform heat treatment outcomes.

- Q: Can insulating fire bricks be used in chimney lining?

- Indeed, insulating fire bricks are a suitable option for chimney lining. These bricks are specifically engineered to endure extreme heat and offer exceptional insulation. Their ability to retain heat within the chimney prevents any loss through the walls, which ultimately enhances the efficiency of fireplaces or stoves. Moreover, their lightweight nature and straightforward installation process have contributed to their popularity in chimney lining projects. Nonetheless, it is crucial to verify that the chosen insulating fire brick meets the requirements for chimney applications and adheres to local building codes and regulations.

- Q: Can insulating fire bricks be used in the construction of smelting crucibles?

- Yes, insulating fire bricks can be used in the construction of smelting crucibles. The high heat resistance and insulating properties of these bricks make them suitable for withstanding the extreme temperatures required in the smelting process.

- Q: Are insulating fire bricks resistant to UV radiation?

- Insulating fire bricks are not typically designed to be resistant to UV radiation. UV radiation from the sun can cause degradation and discoloration of many materials, including fire bricks. Therefore, it is recommended to protect insulating fire bricks from direct exposure to UV radiation, such as by using a protective coating or covering when they are used in outdoor applications. Additionally, prolonged exposure to UV radiation can also affect the thermal and insulating properties of fire bricks, potentially reducing their effectiveness over time. Therefore, it is important to consider UV protection measures when using insulating fire bricks in applications where they may be exposed to direct sunlight.

- Q: How do insulating fire bricks compare to other insulation materials like ceramic fiber?

- Insulating fire bricks are generally denser and more durable compared to ceramic fiber insulation materials. While ceramic fiber offers excellent thermal insulation and is lightweight, insulating fire bricks provide better resistance to high temperatures and mechanical stress. Additionally, insulating fire bricks have lower thermal conductivity and higher compressive strength, making them suitable for applications that require long-term thermal insulation and structural support.

- Q: Can insulating fire bricks be used in refractory lining for steelmaking?

- Yes, insulating fire bricks can be used in refractory lining for steelmaking. They are effective in providing insulation and thermal stability, helping to maintain high temperatures and protect the surrounding structures. Additionally, insulating fire bricks have low thermal conductivity and are lightweight, making them suitable for steelmaking processes that require heat retention and energy efficiency.

- Q: Can insulating fire bricks be used for insulation in solar thermal systems?

- Indeed, insulation in solar thermal systems can be achieved by utilizing insulating fire bricks. These bricks have been specifically engineered to possess a low thermal conductivity, enabling them to effectively capture and retain heat. As a result, they prove to be suitable for insulating various components of a solar thermal system, including the solar collector and storage tank, thereby minimizing heat dissipation and enhancing the system's overall efficiency. Furthermore, insulating fire bricks exhibit remarkable resistance to high temperatures, a critical characteristic in solar thermal systems where extreme temperatures can be encountered. In summary, the utilization of insulating fire bricks as insulation in solar thermal systems serves to enhance performance and diminish energy loss.

- Q: Can insulating fire bricks be used in the construction of lime calciners?

- Indeed, the utilization of insulating fire bricks is feasible when constructing lime calciners. Lime calciners necessitate elevated temperatures for lime production, and insulating fire bricks are specifically engineered to endure and preserve heat. These bricks possess a reduced thermal conductivity, which effectively insulates the calciner and impedes heat dissipation. Furthermore, insulating fire bricks are lightweight, facilitating their handling and installation during the lime calciners' construction process.

- Q: Are insulating fire bricks resistant to sulfur dioxide?

- Insulating fire bricks are generally not resistant to sulfur dioxide. Sulfur dioxide is a highly corrosive gas that can react with the materials used in insulating fire bricks, leading to their degradation and reduced effectiveness. It is important to use refractory materials specifically designed to withstand sulfur dioxide exposure if that is a requirement for the intended application.

Send your message to us

Insulating Fire Brick - Insulation Brick, Insulating Brick, GJM23, GJM26, GJM28, GJM30, GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords