Insulating Fire Brick - Refractory Thermal Insulating Light Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Light Brick Thermal Insulating Fire Brick

High alumina insulating fire brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina Insulating Fire Brick are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Product Applications:

High alumina insulating fire brick are ideal for use in the below applications

Building materials for blast furnace

Building materials for hot-blast stove

Building materials for coke oven

Building materials for steel making furnace

For construction material in steel industry

For ladle

Product Advantages:

CNBM has success in its High alumina insulating fire brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

Excellent thermal stability

High refractoriness under load

Chemical stability and anti-corrision

Small high temperature creep rate

Excellent thermal shock resistance

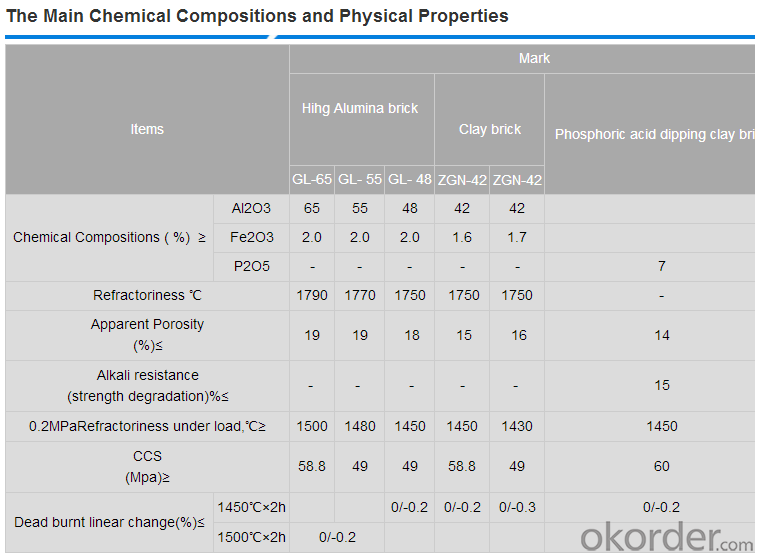

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

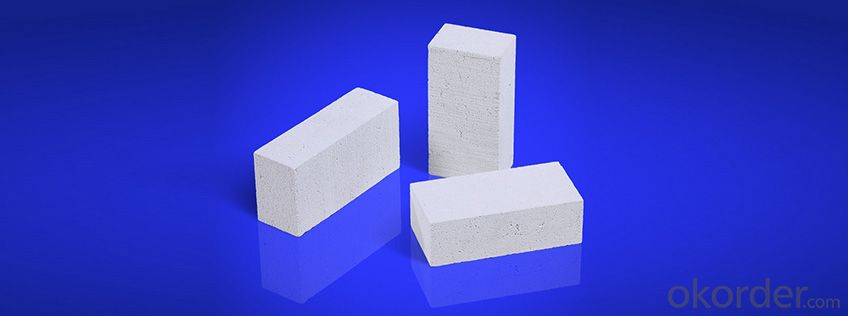

Product Picture

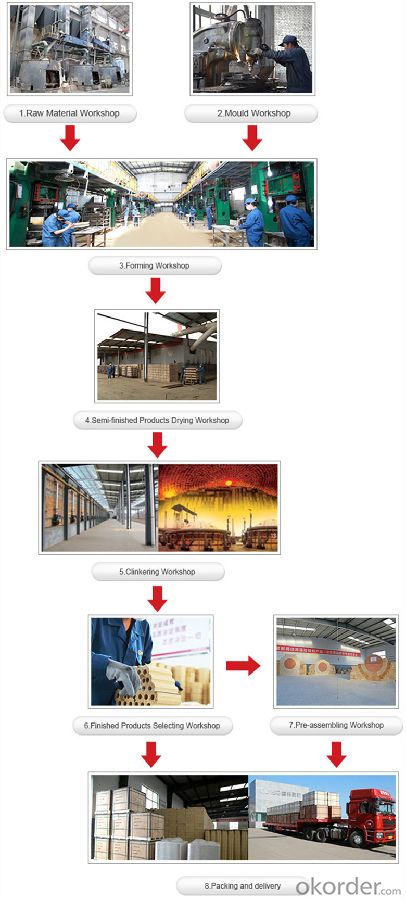

Produce Processing

- Q: Can insulating fire bricks be used in the construction of lime calciners?

- Yes, insulating fire bricks can be used in the construction of lime calciners. Insulating fire bricks are known for their high heat resistance and low thermal conductivity, making them suitable for applications that require insulation and protection against extreme temperatures. In lime calciners, which are used to heat limestone to produce lime, the use of insulating fire bricks can help maintain the desired temperature inside the calciner while minimizing heat loss to the surroundings.

- Q: Can insulating fire bricks be used in residential construction?

- Yes, insulating fire bricks can be used in residential construction. They are commonly used to line fireplaces, wood-burning stoves, and other heating appliances in homes. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for residential applications where heat retention and fire protection are important factors.

- Q: Can insulating fire bricks be used in the construction of refractory linings?

- Yes, insulating fire bricks can be used in the construction of refractory linings. Insulating fire bricks are specifically designed to have excellent thermal insulation properties, making them ideal for applications where high temperatures need to be contained. They are commonly used in the construction of furnaces, kilns, and other high-temperature environments. The insulating properties of these bricks help to reduce heat loss, improve energy efficiency, and maintain a stable temperature within the refractory lining. Additionally, insulating fire bricks are lightweight and easy to handle, making them a practical choice for refractory lining construction.

- Q: Are insulating fire bricks resistant to corrosion?

- Yes, insulating fire bricks are resistant to corrosion.

- Q: Can insulating fire bricks be used for insulation in steam pipes?

- Yes, insulating fire bricks are a suitable option for insulation in steam pipes. These bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They have low thermal conductivity, which means they prevent the transfer of heat effectively. This property makes them ideal for insulating steam pipes, as it helps to minimize heat loss and maintain the temperature of the steam inside the pipes. Additionally, insulating fire bricks are lightweight and easy to install, making them a convenient choice for insulating steam pipes.

- Q: Can insulating fire bricks be used in wood-fired kilns?

- Indeed, wood-fired kilns can utilize insulating fire bricks. These bricks are specifically engineered to endure elevated temperatures and offer exceptional insulation, rendering them an optimal choice for wood-fired kilns. They effectively retain and evenly distribute heat throughout the kiln, guaranteeing efficient and uniform wood firing. Furthermore, their lightweight nature aids in the construction and upkeep of the kiln. Ultimately, the utilization of insulating fire bricks in wood-fired kilns enhances their overall performance and efficiency.

- Q: Can the whole wall of the high-rise building be made of grey insulation bricks?

- If the frame structure, it may be so. What is the length of the whole wall? If it is longer, it is necessary to make a constructional column; if the hole is larger, the edge of the hole needs to be made into a border or a constructional column; if the entrance is small, the edge of the hole is about 300mm and needs solid bricks to build better. South wall thickness can be about 190mm, plus plastering design value of 200mm. Personal comments for reference!

- Q: Are insulating fire bricks resistant to hydrofluoric acid?

- Hydrofluoric acid is a highly corrosive substance capable of attacking and dissolving various materials, including fire bricks, which lack resistance to it. Therefore, it is crucial to exercise utmost caution and employ suitable protective gear while dealing with this hazardous substance.

- Q: Can insulating fire bricks be used in the construction of industrial furnaces?

- Yes, insulating fire bricks can be used in the construction of industrial furnaces. Insulating fire bricks are specifically designed to withstand high temperatures and thermal shocks, making them suitable for use in furnaces where temperatures can reach extremely high levels. These bricks have low thermal conductivity, which helps to minimize heat loss and improve energy efficiency in the furnace. Additionally, insulating fire bricks are lightweight and easy to handle, making them convenient for construction purposes. Overall, their excellent insulation and heat-resistant properties make insulating fire bricks an ideal choice for industrial furnace construction.

- Q: Can insulating fire bricks be used in thermal oxidizers?

- Insulating fire bricks are indeed applicable for thermal oxidizers. These bricks are specifically designed to possess low thermal conductivity, enabling them to effectively diminish heat transfer and conserve energy in high-temperature scenarios. Thermal oxidizers, on the other hand, are utilized as devices for treating industrial exhaust gases through the process of oxidizing pollutants at elevated temperatures. By incorporating insulating fire bricks into the construction of thermal oxidizers, the system can confine heat within, ensuring efficient combustion while minimizing heat loss to the surrounding environment. Consequently, this not only enhances the overall thermal efficiency of the thermal oxidizer but also aids in decreasing energy consumption and operational expenses. Furthermore, insulating fire bricks possess remarkable resistance against thermal shock and display exceptional insulating properties, rendering them suitable for the challenging and rigorous conditions commonly encountered in thermal oxidizers.

Send your message to us

Insulating Fire Brick - Refractory Thermal Insulating Light Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords