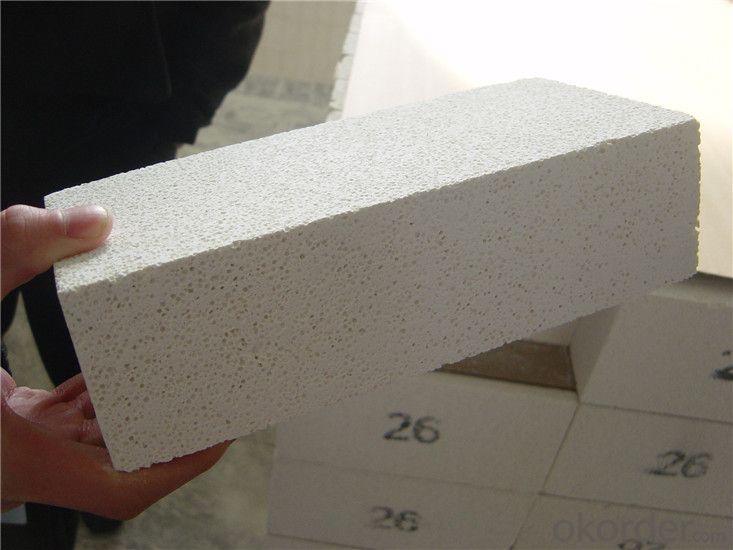

Insulating Fire Brick Lightweight Fire Clay

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Insulating Fire Brick Technical index

Product No. | IFB70 | IFB60 | IFB50 | IFB40 |

Al2O3 | 68%-72% | 58%-62% | 48%-52% | 38%-40% |

Refractoriness (°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1790 |

Bulk density (g/cm3) | 2.50-2.60 | 2.35-2.45 | 2.20-2.30 | 2.10-2.20 |

Apparent porosity (%) | 22 | 19-22 | 17-20 | 17-20 |

Cold Crushing strength (kg) | 480-510 | 450-480 | 430-450 | 390-430 |

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

- Q: What are the safety precautions when working with insulating fire bricks?

- To ensure the safety of yourself and others when working with insulating fire bricks, it is crucial to follow various safety measures. Consider the following key precautions: 1. Personal protective equipment (PPE): Protect yourself by wearing suitable PPE, such as heat-resistant gloves, long-sleeved clothing, safety goggles, and a respiratory mask. These items will safeguard you against potential burns, cuts, and the inhalation of harmful dust or fumes. 2. Adequate ventilation: Work in a well-ventilated area or utilize local exhaust ventilation to minimize exposure to dust and fumes that may be released during the handling or cutting of the bricks. 3. Fire prevention: Keep a fire extinguisher close by and ensure that the workspace is free of flammable materials. Although insulating fire bricks are highly refractory and can withstand high temperatures, it is still crucial to prevent accidental fires. 4. Proper lifting techniques: As insulating fire bricks can be heavy, employ correct lifting techniques and avoid overexertion to prevent strains or injuries. If necessary, use mechanical aids like trolleys or lifting equipment to move the bricks. 5. Cutting and grinding: Utilize appropriate tools in good working condition when cutting or grinding the bricks. This will minimize the risk of accidents or injuries. Pay attention to sharp edges and wear protective gloves to prevent cuts. 6. Temperature control: While insulating fire bricks are designed to handle high temperatures, avoid direct contact with hot surfaces. Use suitable tools or equipment to handle the bricks when they are at an elevated temperature. 7. Storage and handling: Store the bricks in a cool, dry place away from direct sunlight or extreme temperatures. Avoid stacking them too high to mitigate the risk of collapse or toppling. 8. Training and knowledge: Ensure that you have undergone proper training and are familiar with the characteristics and properties of insulating fire bricks. Understand their limitations and adhere to the manufacturer's guidelines for safe handling and usage. By adhering to these safety precautions, you can significantly decrease the likelihood of accidents, injuries, and health hazards when working with insulating fire bricks. Always prioritize safety in any workplace.

- Q: Are insulating fire bricks resistant to carbon monoxide attack?

- Yes, insulating fire bricks are generally resistant to carbon monoxide attack. Insulating fire bricks are made from materials that have a high resistance to high temperatures and chemical corrosion, including carbon monoxide. These bricks are often used in applications where high temperatures and exposure to various gases, including carbon monoxide, are common, such as in furnaces, kilns, and fireplaces. The composition of insulating fire bricks allows them to withstand prolonged exposure to carbon monoxide without deteriorating or reacting with the gas. However, it is important to note that prolonged exposure to extremely high levels of carbon monoxide can eventually cause damage to any material, including insulating fire bricks. Therefore, it is still necessary to ensure proper ventilation and safety measures when dealing with carbon monoxide in any setting.

- Q: How do insulating fire bricks affect the overall fire resistance of a structure?

- The overall fire resistance of a structure is greatly enhanced by the presence of insulating fire bricks. These specialized bricks are designed to endure high temperatures and serve as an effective barrier against heat. By insulating the structure, they aid in minimizing heat transfer and the propagation of fire. The low thermal conductivity of insulating fire bricks allows them to resist heat transmission. This characteristic enables them to absorb and retain heat energy, preventing it from spreading to other parts of the structure. Consequently, the fire remains contained within a specific area, reducing the risk of it spreading to adjacent spaces. Additionally, insulating fire bricks possess a high melting point, rendering them highly resistant to heat. This quality enables them to endure prolonged exposure to intense temperatures without warping or disintegrating. By preserving their structural integrity, these bricks ensure the stability and overall integrity of the structure during a fire incident. Furthermore, insulating fire bricks serve as a barrier against flames and combustion gases. Their dense composition obstructs the passage of flames and smoke, preventing them from permeating the structure. This containment aids in limiting the damage caused by fire and provides occupants with valuable time to evacuate safely. In summary, the utilization of insulating fire bricks in constructing a structure significantly enhances its fire resistance. They provide insulation, prevent the propagation of fire, maintain structural stability, and act as a barrier against flames and smoke. By minimizing heat transfer and confining the fire, insulating fire bricks play a vital role in safeguarding the structure and its occupants during a fire emergency.

- Q: Can insulating fire bricks be used in paper mills?

- Insulating fire bricks are indeed applicable for use in paper mills. They are widely employed in various industries that necessitate effective insulation against elevated temperatures, including steel, glass, and ceramics. Within paper mills, where activities like drying, heating, and burning take place, insulating fire bricks offer an ideal solution for lining kilns, furnaces, and other equipment. Their exceptional thermal insulation properties and ability to withstand extreme temperatures render them highly suitable for deployment in paper mills, where heat plays an indispensable role in the manufacturing process. Furthermore, these bricks possess the advantages of being lightweight and exhibiting low thermal conductivity, enabling efficient heat retention and yielding energy savings.

- Q: Are insulating fire bricks resistant to thermal conductivity?

- Insulating fire bricks possess the capability of withstanding thermal conductivity due to their design. These bricks are composed of materials that possess low thermal conductivity, such as lightweight refractory fibers or insulating substances like vermiculite or perlite. The main objective of insulating fire bricks is to offer thermal insulation and hinder the transfer of heat, making them a perfect fit for situations where temperature control is of utmost importance, like in kilns, furnaces, or fireplaces. By minimizing thermal conductivity, insulating fire bricks aid in preserving heat within the desired area and minimizing energy loss, thus proving to be an effective insulation choice in high-temperature environments.

- Q: Can insulating fire bricks be used for insulation in heat treatment furnaces?

- Indeed, insulation in heat treatment furnaces can be achieved through the utilization of insulating fire bricks. These bricks are specially engineered to endure extreme temperatures and offer exceptional thermal insulation properties. With their low thermal conductivity, they effectively trap heat within the furnace. Moreover, their lightweight composition facilitates effortless handling and installation. Insulating fire bricks find widespread application in diverse heat treatment procedures, including annealing, tempering, and hardening, guaranteeing utmost heat retention and energy efficiency within the furnace.

- Q: Are insulating fire bricks resistant to electrical conductivity?

- Yes, insulating fire bricks are resistant to electrical conductivity. These bricks are made from materials that have low electrical conductivity, such as ceramic fibers or insulating refractory materials. The main purpose of insulating fire bricks is to provide thermal insulation, making them ideal for applications where high temperatures need to be contained. As a result of their low electrical conductivity, insulating fire bricks do not conduct electricity and are used to line electrical furnaces, kilns, and other high-temperature equipment where electrical insulation is required.

- Q: Are insulating fire bricks suitable for insulation in boilers?

- Yes, insulating fire bricks are suitable for insulation in boilers. Insulating fire bricks are made from lightweight materials such as clay and alumina, which have excellent insulating properties. They have a low thermal conductivity, meaning they are effective at preventing heat transfer and can help to significantly reduce heat loss in boilers. Additionally, insulating fire bricks are resistant to high temperatures, making them suitable for use in boilers where high heat is generated. They are also durable and can withstand the harsh conditions inside a boiler, including exposure to intense heat and corrosive gases. Overall, insulating fire bricks are a popular choice for boiler insulation due to their thermal efficiency and ability to withstand high temperatures.

- Q: Are insulating fire bricks resistant to chlorine gas?

- Generally, insulating fire bricks possess resistance to chlorine gas. These bricks are composed of refractory materials that are formulated to endure high temperatures and combat chemical corrosion. As chlorine gas is highly reactive, it has the potential to corrode or harm various materials. However, insulating fire bricks exhibit a strong resistance to chemical attack, thereby making them appropriate for situations where exposure to chlorine gas is likely. It should be noted that the composition and quality of these bricks may differ, hence it is advisable to consult the manufacturer or supplier for precise details regarding their resistance to chlorine gas.

- Q: Can the whole wall of the high-rise building be made of grey insulation bricks?

- If the frame structure, it may be so. What is the length of the whole wall? If it is longer, it is necessary to make a constructional column; if the hole is larger, the edge of the hole needs to be made into a border or a constructional column; if the entrance is small, the edge of the hole is about 300mm and needs solid bricks to build better. South wall thickness can be about 190mm, plus plastering design value of 200mm. Personal comments for reference!

Send your message to us

Insulating Fire Brick Lightweight Fire Clay

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords