Insulating Fire Brick GJM23 26 28 30 for Different Applications in Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 watt

- Supply Capability:

- 1000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

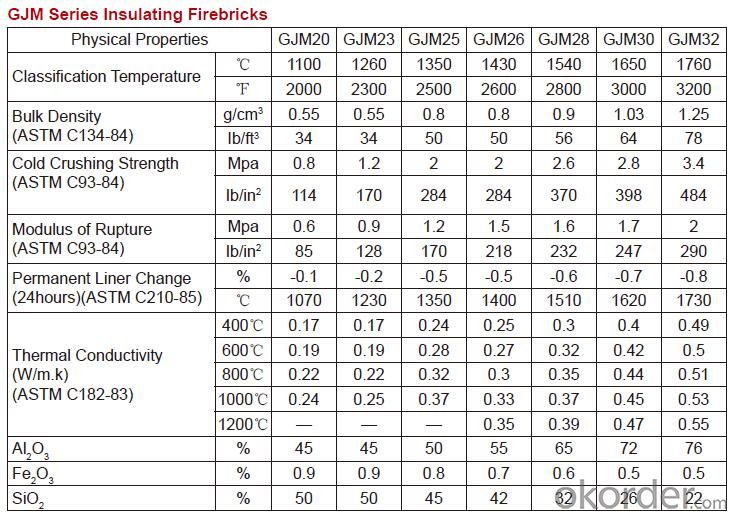

CMAX insulating firebricks are classified under temperature between 1100℃ to 1700℃, manufactured from high purity alumina clay.

Features

◆Light weight and low thermal conductivity

◆Low heat storage

◆Low iron and impurities

◆High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Technical Data

This information, subject to change, is offered solely for your consideration. Users of our products should make their

own tests to determine the suitability of each product for their particular purposes.

Company Information

CNBM International Corp., established in 2004, is the business entity for international business and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

Production Control

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: Are insulating fire bricks suitable for use in the construction of lime kilns?

- Yes, insulating fire bricks are suitable for use in the construction of lime kilns. Insulating fire bricks are specifically designed to have low thermal conductivity, which means they are able to retain heat and prevent heat loss. This is important in lime kilns as they require high temperatures to efficiently convert limestone into lime. By using insulating fire bricks, the heat generated in the kiln can be maintained more effectively, resulting in improved energy efficiency and reduced fuel consumption. Additionally, insulating fire bricks are lightweight and easy to handle, making them ideal for constructing lime kilns. Overall, insulating fire bricks are a reliable and effective choice for the construction of lime kilns.

- Q: Are insulating fire bricks resistant to flame impingement?

- Yes, insulating fire bricks are resistant to flame impingement.

- Q: Can insulating fire bricks be used in the construction of steel production furnaces?

- Yes, insulating fire bricks can be used in the construction of steel production furnaces. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for use in various industrial applications, including steel production. These bricks are made from lightweight materials that have low thermal conductivity, allowing them to effectively reduce heat loss and improve energy efficiency in furnaces. Additionally, insulating fire bricks have good resistance to thermal shock, which is important in steel production processes that involve rapid heating and cooling. Overall, the use of insulating fire bricks in the construction of steel production furnaces can help optimize performance, reduce energy consumption, and enhance the overall efficiency of the steelmaking process.

- Q: Can insulating fire bricks be used in ceramic fiber blankets?

- It is not possible to use insulating fire bricks in ceramic fiber blankets. Insulating fire bricks are dense and solid, specifically designed to offer insulation and endure high temperatures in settings like furnaces and kilns. Conversely, ceramic fiber blankets are flexible and lightweight, consisting of ceramic fibers that provide exceptional thermal insulation. They are frequently utilized as insulation in diverse industrial applications, such as lining for furnaces, boilers, and high-temperature equipment. Combining insulating fire bricks with ceramic fiber blankets would not yield effective results because these materials possess distinct properties and serve different purposes.

- Q: Can activated carbon be antiseptic?

- Activated carbon is mainly with adsorption properties, there is no direct anti-corrosion effect.

- Q: Are insulating fire bricks resistant to phosphoric acid?

- Phosphoric acid, being a strong acid, has the potential to react with and corrode various materials, including fire bricks. Although certain fire bricks may possess a degree of resistance to acidic conditions, insulating fire bricks are generally not equipped to endure prolonged exposure to phosphoric acid without experiencing notable deterioration. As a result, it is advisable to employ acid-resistant materials like acid-resistant bricks or linings when handling phosphoric acid or other potent acids.

- Q: Do insulating fire bricks have a high fire resistance rating?

- Yes, insulating fire bricks have a high fire resistance rating. Insulating fire bricks are specially designed to withstand high temperatures and provide excellent insulation against heat transfer. They are made from high-purity refractory materials, such as alumina and silica, which have a high melting point and can withstand extreme heat. These bricks are capable of withstanding temperatures of up to 3000°F (1650°C) and have a thermal conductivity that is much lower than regular bricks or other materials. This makes them ideal for use in applications where high fire resistance is required, such as in industrial furnaces, kilns, fireplaces, and chimneys. Additionally, their insulating properties help to reduce heat loss, making them energy-efficient and cost-effective.

- Q: Can insulating fire bricks be used for structural purposes?

- Insulating fire bricks are primarily designed to provide insulation rather than structural support. While they can withstand high temperatures and are resistant to thermal shock, they are not typically intended to bear heavy loads or serve as load-bearing components in structural applications. Insulating fire bricks are more commonly used in situations where thermal insulation is required, such as lining kilns, furnaces, and fireplaces. For structural purposes, it is generally recommended to use refractory bricks or other materials that are specifically engineered to provide strength and durability under load.

- Q: Can insulating fire bricks be used in the insulation of boilers?

- Yes, insulating fire bricks can be used in the insulation of boilers. Insulating fire bricks are designed to withstand high temperatures and are highly effective at insulating against heat transfer. They have low thermal conductivity, which means they can help reduce heat loss from the boiler and improve its overall energy efficiency. Additionally, insulating fire bricks are lightweight and easy to install, making them an ideal choice for boiler insulation.

- Q: Can insulating fire bricks be used for insulation in ovens and kilns?

- Insulating fire bricks are indeed suitable for insulation in ovens and kilns. These bricks are specially designed to withstand high temperatures and offer exceptional thermal insulation. They are composed of lightweight materials such as clay and other refractory substances with low thermal conductivity. Consequently, they possess the ability to effectively retain heat and prevent its escape, making them an ideal choice for ovens and kilns where heat retention is of utmost importance. Furthermore, insulating fire bricks possess resistance against thermal shock, enabling them to endure rapid temperature changes without cracking or breaking. Ultimately, insulating fire bricks guarantee efficient heat distribution and energy conservation, making them a reliable option for insulating ovens and kilns.

Send your message to us

Insulating Fire Brick GJM23 26 28 30 for Different Applications in Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 watt

- Supply Capability:

- 1000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords