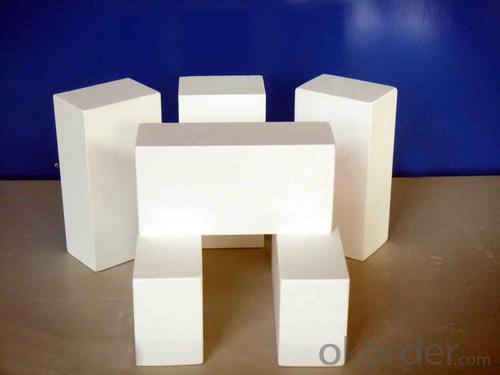

Insulating Fire Brick - DJM 26 Lightweight

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

DJM 26 Light Weight Insulating fire brickconforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

DJM 26 Light Weight Insulating fire brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used for insulation in heat recovery systems?

- Yes, insulating fire bricks can be used for insulation in heat recovery systems. These bricks have high thermal resistance, low thermal conductivity, and can withstand high temperatures, making them suitable for insulating and retaining heat in heat recovery systems.

- Q: Can insulating fire bricks be used in waste incineration plants?

- Insulating fire bricks are indeed applicable in waste incineration plants. Their ability to endure high temperatures renders them suitable for the exceedingly hot surroundings found in these plants. These bricks are crafted from lightweight materials that possess exceptional thermal insulation properties, thus aiding in minimizing heat loss and enhancing energy efficiency during the incineration procedure. Moreover, insulating fire bricks exhibit commendable resistance to both chemical and thermal shock, a crucial attribute in waste incineration plants where diverse waste materials are combusted. Overall, the incorporation of insulating fire bricks in waste incineration plants contributes to heightened insulation, increased energy efficiency, and enhanced incineration process performance.

- Q: Are insulating fire bricks suitable for the insulation of chimneys?

- Yes, insulating fire bricks are suitable for the insulation of chimneys. Insulating fire bricks are specially designed to withstand high temperatures and provide effective insulation, making them ideal for use in chimneys. They have a high thermal conductivity, which means they can retain heat and prevent it from escaping, thereby improving the efficiency of the chimney. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is particularly important in chimneys, where the temperature can fluctuate dramatically during the combustion process. Overall, insulating fire bricks are a reliable choice for chimney insulation, as they offer excellent heat retention and durability.

- Q: How do insulating fire bricks perform in terms of sound insulation?

- Insulating fire bricks are primarily designed to provide excellent thermal insulation, but their performance in terms of sound insulation may vary. While they can offer some level of sound reduction due to their dense and non-porous nature, they are not specifically engineered for soundproofing purposes. The level of sound insulation provided by insulating fire bricks will depend on various factors such as brick thickness, density, and the frequency of the sound. In general, insulating fire bricks can help reduce high-frequency noises to some extent, but they may not be as effective in blocking low-frequency sounds. For better sound insulation, specialized acoustic materials or construction techniques may be more suitable.

- Q: Can insulating fire bricks be used in high-temperature filters?

- Yes, insulating fire bricks can be used in high-temperature filters. These bricks are designed to withstand extreme temperatures and provide excellent insulation. They can effectively trap and filter out impurities in high-temperature environments, making them suitable for use in high-temperature filters.

- Q: How do insulating fire bricks contribute to reducing heat loss?

- Insulating fire bricks contribute to reducing heat loss by their unique thermal properties and design. These bricks are made from insulating materials, such as ceramic fibers or lightweight refractory aggregates, which have low thermal conductivity. This means that they are not easily conductive to heat transfer, preventing the transfer of heat from one side of the brick to the other. Furthermore, the structure of insulating fire bricks includes small air pockets or voids within the material. These air pockets act as thermal barriers, as air is a poor conductor of heat. When heat tries to pass through the brick, it gets trapped within these voids, significantly reducing heat transfer. The insulating properties of these bricks help to create a thermal barrier in various applications, such as industrial furnaces, kilns, and fireplaces. By using insulating fire bricks as lining or insulation material, the heat loss from these systems is minimized. This not only helps to maintain a more stable and uniform temperature within the enclosed space but also increases energy efficiency by reducing the amount of heat wasted. In addition, insulating fire bricks are resistant to high temperatures, ensuring that they do not degrade or lose their insulating capabilities when exposed to extreme heat. This durability allows them to provide long-lasting insulation and contribute to reducing heat loss over an extended period. Overall, insulating fire bricks are highly effective in reducing heat loss due to their low thermal conductivity, presence of air pockets, and high-temperature resistance. Their incorporation in various thermal systems helps to conserve energy, improve thermal efficiency, and create a more comfortable and controlled environment.

- Q: What is composite sintering insulation bricks?

- The brick belongs to the porous brick and has good heat preservation performance. Reached the national 50%~65% energy efficiency standards. High safety (no crack, no seepage), strong durability (with building life), economy (self insulation, no need to increase the cost of insulation).

- Q: Can insulating fire bricks be used in the construction of glass melting tanks?

- Yes, insulating fire bricks can be used in the construction of glass melting tanks. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for applications such as glass melting tanks where maintaining consistent and controlled heat is crucial.

- Q: Can insulating fire bricks be used in pizza ovens or outdoor grills?

- Yes, insulating fire bricks can be used in pizza ovens or outdoor grills. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for retaining heat and creating consistent cooking conditions in pizza ovens and grills.

- Q: Are insulating fire bricks suitable for use in the construction of smelters?

- Yes, insulating fire bricks are suitable for use in the construction of smelters. These bricks are designed to withstand high temperatures and provide excellent insulation properties, making them ideal for lining the walls and floors of smelters. They help to retain heat, reduce energy loss, and protect the structure from extreme heat. Additionally, insulating fire bricks are lightweight and easy to install, making them a preferred choice for smelter construction.

Send your message to us

Insulating Fire Brick - DJM 26 Lightweight

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords