Insulating Fire Brick GJM26 Light Weight and Low Thermal Conductivity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Firebricks

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature of Insulating Firebricks

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulating Firebricks

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

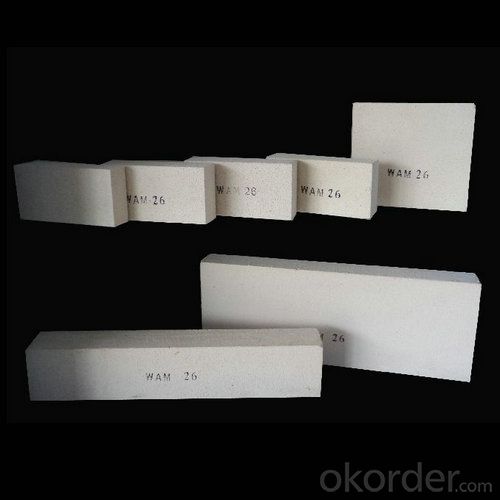

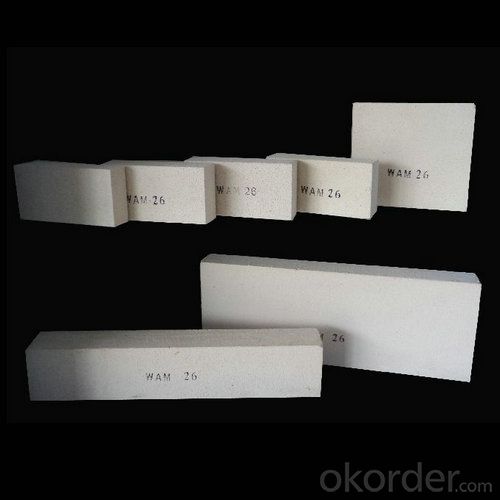

Images of Insulating Firebricks

Technical Data of Insulating Firebricks

INSULATING FIRE BRICK---GJM26

Classification Temperature (℉/℃) 2600/1430

Bulk Density (g/cm3) ≤0.8

Thermal Conductivity

800℃, W/m.K ≤0.35

1000℃, W/m.K ≤0.39

1200℃, W/m.K ≤0.43

Reheating Linear Change (%) 1410℃×12h

≤0.7

Chemical Composition (%)

Al2O3 ≥55

Fe2O3 ≤0.7

Company Introduction

Who CNBM is

CNBM is a Fortune 500 and a governmental owned National Building Material company in Beijing, China.

What CNBM Can Do

We can supply ALL KINDS OF REFRACTORIES BRICK/CASTABLE and CERAMIC FIBER PRODUCTS in high quality and competitive price.

What Certification CNBM Have

FAQ

If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervisor.

I’m not satisfied with the refractory materials I used before, can you propose more suitable pro

Yes. Please give us the problems you faced, your requirements and the technical data of the products you used before. That we will give you our suggestion and propose the solution based on your special requirements.

What’s the lead time for my order?

It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Can you offer Door-to-Door delivery?

Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

What is the minimum quantity?

There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q: What is the typical modulus of rupture of an insulating fire brick?

- The modulus of rupture of an insulating fire brick can differ based on the brick's particular composition and manufacturing method. On average, insulating fire bricks usually have a modulus of rupture ranging from 1 to 10 megapascals (MPa). This indicates that these bricks can endure a bending force or pressure of 1 to 10 MPa before they fracture or break. It should be emphasized that the modulus of rupture can be affected by factors like the density, porosity, and chemical composition of the insulating fire brick.

- Q: How does an insulating fire brick differ from a regular fire brick?

- An insulating fire brick differs from a regular fire brick in terms of its composition and thermal conductivity. Insulating fire bricks are made from lightweight materials that have low thermal conductivity, allowing them to retain heat more efficiently and provide better insulation. On the other hand, regular fire bricks are typically denser and have higher thermal conductivity, making them suitable for applications where heat retention is not the primary concern.

- Q: What is the porosity of insulating fire bricks?

- The porosity of insulating fire bricks typically ranges from 40% to 70%, allowing for excellent thermal insulation properties.

- Q: Can insulating fire bricks be used in residential fireplaces?

- Residential fireplaces can indeed utilize insulating fire bricks. These specialized bricks are engineered to endure extreme temperatures while providing exceptional insulation, rendering them an apt option for constructing fireplaces. These bricks have the ability to retain heat, boost energy efficiency, and prevent heat loss. Moreover, they offer superior defense against thermal shock, a crucial element for enduring the intense heat produced by a fireplace. Furthermore, insulating fire bricks are lightweight, easy to manipulate, and can be effortlessly shaped or trimmed to fit any fireplace design or size. All in all, incorporating insulating fire bricks into residential fireplaces is a prudent decision for homeowners seeking to enhance their fireplace's performance and safety.

- Q: Can insulating fire bricks be used in fireplace construction?

- Yes, insulating fire bricks can be used in fireplace construction. They are designed to withstand high temperatures and provide excellent insulation, making them a suitable choice for building fireplaces.

- Q: Energy saving bricks or bricks?

- Energy saving brick may be cement slag, or cement, water residue, cement, coal ash, etc. overview

- Q: Can insulating fire bricks be used in the construction of autoclaves?

- Yes, insulating fire bricks can be used in the construction of autoclaves. Autoclaves require materials that can withstand high temperatures and pressures, and insulating fire bricks are designed to have excellent thermal resistance and insulation properties. These bricks are made from refractory materials like alumina, silica, and other additives that allow them to withstand extreme temperatures and thermal shocks. They are also lightweight and have low thermal conductivity, which helps to minimize heat loss and improve energy efficiency in autoclaves. Additionally, insulating fire bricks have good load-bearing capacity, making them suitable for the structural components of autoclaves. Overall, the use of insulating fire bricks in the construction of autoclaves helps to ensure the safety and efficiency of the equipment.

- Q: Is it possible to recycle used insulating fire bricks?

- It is indeed feasible to recycle insulating fire bricks that have been used. Insulating fire bricks consist of a range of materials, including alumina, silica, and other refractory materials. These materials can be dismantled and utilized again in the creation of fresh bricks or alternative refractory products. The recycling of used insulating fire bricks aids in the reduction of the need for fresh raw materials and the mitigation of waste. Nevertheless, it is crucial to acknowledge that not all recycling centers or facilities may accept insulating fire bricks. It is therefore advisable to verify with local recycling programs or specialized recycling companies that handle refractory materials.

- Q: Are insulating fire bricks suitable for use in the construction of drying ovens?

- Insulating fire bricks are indeed suitable for use in the construction of drying ovens. Their design aims to minimize thermal conductivity, enabling efficient heat retention within the oven. This particular feature is crucial for drying ovens as it promotes consistent and uniform temperature maintenance throughout the drying process. Moreover, insulating fire bricks possess remarkable resistance to thermal shock, ensuring they can endure rapid temperature changes that may occur during the oven's heating and cooling cycles. This durability guarantees that the bricks will not crack or break under extreme temperature conditions. Additionally, these bricks are lightweight and easy to handle, providing convenience during installation in drying ovens. Overall, their excellent insulation and thermal stability qualities make them a highly appropriate option for constructing drying ovens.

- Q: Can insulating fire bricks be used in high-temperature ducts?

- Insulating fire bricks can indeed be used in high-temperature ducts. These bricks are specially designed to withstand extreme temperatures, making them an ideal choice for applications where heat retention and insulation are crucial. With their low thermal conductivity and high resistance to thermal shock, insulating fire bricks can effectively trap heat within the ducts, preventing any loss of energy and ensuring efficient heat transfer. Additionally, their lightweight nature makes them easy to install and handle, while their durability allows them to withstand the harsh conditions of high-temperature environments. Overall, insulating fire bricks are a reliable and effective solution for insulating high-temperature ducts.

Send your message to us

Insulating Fire Brick GJM26 Light Weight and Low Thermal Conductivity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords