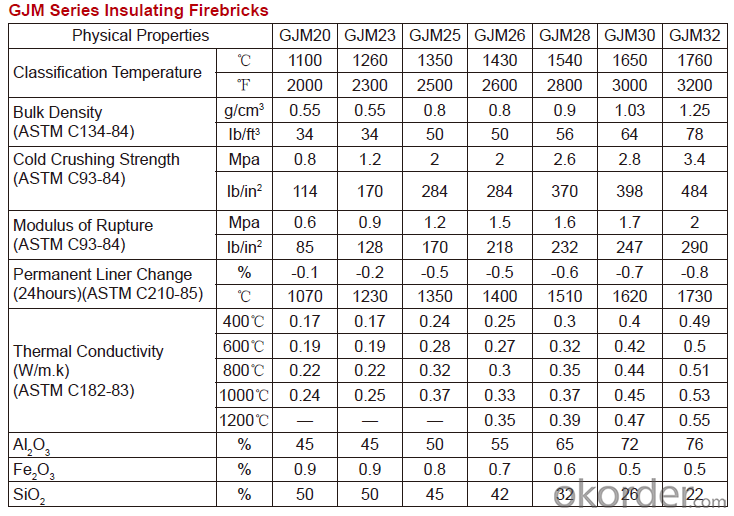

Insulating Fire Brick - GJM 26 Light Dense Mullite Insulation Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a refractory material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment and good service

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How do insulating fire bricks affect the overall fire safety of a structure?

- The overall fire safety of a structure is greatly improved by the use of insulating fire bricks. These bricks are specifically designed to withstand high temperatures and provide excellent insulation, making them ideal for applications that require heat containment. By effectively insulating the structure, these bricks help minimize the spread of fire and heat transfer. Their low thermal conductivity slows down the rate at which heat is conducted through the walls, ceiling, and floors of a building. This is crucial in preventing the fire from spreading to adjacent areas or neighboring structures. In addition, insulating fire bricks act as a barrier to the penetration of flames and hot gases, further contributing to the fire safety of a structure. Their ability to withstand high temperatures without compromising their structural integrity effectively contains the fire within a confined area. This containment provides valuable time for evacuation or firefighting efforts. Furthermore, insulating fire bricks are known for their excellent fire resistance properties. They are manufactured using refractory materials that can withstand extremely high temperatures without melting or disintegrating. This resistance to heat ensures that the bricks maintain their structural integrity even under intense fire conditions, providing a reliable fire protection barrier. Apart from their fire resistance properties, insulating fire bricks also possess excellent insulation capabilities. They have low thermal conductivity, meaning they are highly effective in preventing heat transfer. By reducing the rate of heat transfer, these bricks help maintain a cooler temperature on the non-fire side. This is particularly beneficial for structures that require temperature control, such as industrial furnaces or kilns. In summary, insulating fire bricks significantly enhance the fire safety of a structure by minimizing the spread of fire, acting as a barrier to flames and hot gases, and withstanding high temperatures without compromising their integrity. Their insulation properties also contribute to maintaining a cooler environment on the non-fire side. Therefore, incorporating insulating fire bricks into the construction of a building greatly improves its ability to withstand and contain fires, ultimately ensuring the safety of occupants and reducing property damage.

- Q: Are insulating fire bricks easy to cut or shape?

- Yes, insulating fire bricks are relatively easy to cut or shape. They can be cut using basic tools such as a saw or a knife, and they can also be shaped by using a chisel or sandpaper. Their soft and lightweight composition allows for easier manipulation and customization to fit specific requirements.

- Q: What is the price of fireproof insulation material?

- A preliminary understanding of price through online preliminary understanding, now generally the size of the opening of the cable insulation material manufacturers are on business, early online now have a preliminary understanding, manufacturers investigation after considering cooperation.

- Q: How do insulating fire bricks compare to other insulation materials?

- Insulating fire bricks are superior to other insulation materials in terms of their high heat resistance, durability, and ability to withstand extreme temperatures. They offer excellent thermal insulation properties, low thermal conductivity, and are capable of retaining heat for prolonged periods. Compared to traditional insulation materials like fiberglass and mineral wool, insulating fire bricks provide superior insulation performance and are more suitable for applications requiring high-temperature resistance, such as furnaces, kilns, and industrial ovens.

- Q: Can insulating fire bricks be used in the construction of brick kilns?

- Yes, insulating fire bricks can be used in the construction of brick kilns. Insulating fire bricks are specifically designed to have high thermal resistance, which makes them ideal for applications where insulation is required. In brick kilns, insulating fire bricks can be used to line the walls, floor, and roof of the kiln, helping to retain heat and improve energy efficiency. These bricks are capable of withstanding high temperatures and can provide insulation against the heat generated during the firing process. Additionally, insulating fire bricks can also help reduce heat loss, resulting in faster and more efficient firing cycles. Overall, using insulating fire bricks in the construction of brick kilns can enhance their performance and contribute to more effective and sustainable kiln operation.

- Q: Can insulating fire bricks be used in thermal power plants?

- Yes, insulating fire bricks can be used in thermal power plants. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in power plants where heat is generated and thermal efficiency is crucial. They help to reduce heat loss, improve energy efficiency, and maintain a stable and controlled environment within the power plant.

- Q: Can insulating fire bricks be used for insulation in cryogenic applications?

- Indeed, insulating fire bricks have the capacity to be utilized for insulation purposes in cryogenic applications. These bricks are fabricated from lightweight refractory materials possessing minimal thermal conductivity, thereby rendering them exceptionally efficient in diminishing heat transmission. The insulation materials employed in cryogenic applications must possess the capability to endure exceedingly low temperatures and impede heat escape. Insulating fire bricks exhibit remarkable thermal stability, enabling them to sustain their insulation characteristics even when subjected to cryogenic temperatures. Consequently, they are frequently employed in cryogenic storage tanks, pipelines, and various equipment to furnish insulation and curtail heat transmission.

- Q: Are insulating fire bricks resistant to thermal bridging?

- Yes, insulating fire bricks are resistant to thermal bridging. These bricks are designed to minimize heat transfer by reducing thermal conductivity, making them an effective solution for preventing thermal bridging in various applications.

- Q: Can insulating fire bricks be used in outdoor applications?

- Insulating fire bricks are specifically designed for high-temperature applications and are commonly used in indoor environments such as kilns, furnaces, and ovens. While they are not typically recommended for outdoor applications, there are certain circumstances where they can be used with caution. Insulating fire bricks are made from lightweight refractory materials that provide excellent insulation and heat resistance. However, they are not as durable or weather-resistant as other types of bricks, such as clay or concrete bricks, which are more suitable for outdoor use. In outdoor applications, insulating fire bricks may be exposed to harsh weather conditions, including rain, snow, extreme temperatures, and UV radiation, which can cause them to deteriorate and lose their insulating properties over time. Additionally, these bricks are more susceptible to cracking and damage due to thermal expansion and contraction caused by temperature fluctuations. If you need to use insulating fire bricks in an outdoor application, it is important to take extra precautions to protect them from the elements. This can include using weatherproof coatings or sealants to minimize water absorption and prevent damage from freezing and thawing cycles. It is also crucial to ensure proper drainage and ventilation to prevent moisture accumulation, as excessive moisture can compromise the insulation properties of these bricks. Overall, while insulating fire bricks can be used in outdoor applications under specific conditions, it is generally recommended to use more suitable materials for long-term durability and performance.

- Q: Can insulating fire bricks be used as a thermal barrier?

- Indeed, insulating fire bricks have the potential to function as a thermal barrier. Specifically engineered with low thermal conductivity, these bricks are adept at reducing heat transfer. Consequently, they are an optimal selection for thermal insulation purposes. Their widespread usage is observed in industries that entail elevated temperatures, including furnaces, kilns, and other heat-intensive procedures. By employing insulating fire bricks, heat loss can be minimized, steady temperatures can be maintained, and energy efficiency can be enhanced. Furthermore, their lightweight composition facilitates effortless handling and installation, thereby augmenting their suitability as a thermal barrier.

Send your message to us

Insulating Fire Brick - GJM 26 Light Dense Mullite Insulation Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords