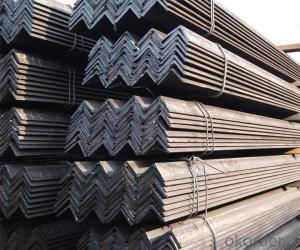

Hot Rolled Steel Bar Equal Bar Unequal Bar SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Bar Equal Bar Unequal Bar SS400 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Bar Equal Bar Unequal Bar SS400 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Bar Equal Bar Unequal Bar SS400 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

Images:

- Q: How do steel angles contribute to the overall aesthetic of a structure?

- Steel angles can contribute to the overall aesthetic of a structure in several ways. Firstly, their clean and sleek lines can add a modern and contemporary look to the design. The sharp edges and precise angles of steel angles can create a sense of strength and solidity, giving the structure a bold and industrial feel. Additionally, steel angles can be used to create interesting and dynamic shapes within the architecture. Their versatility allows for unique and eye-catching designs, such as cantilevered balconies or intricate lattice patterns. These visually appealing features can become focal points of the structure and enhance its overall aesthetic appeal. Moreover, steel angles can be used to create a sense of rhythm and repetition in the design. By incorporating them in a consistent pattern or arrangement, they can create a visual harmony and balance. This repetition can be particularly effective in large-scale structures, where the steel angles can help break up the monotony of the façade and add visual interest. Furthermore, steel angles can also contribute to the overall durability and longevity of the structure, which in turn enhances its aesthetic value. Steel is known for its strength and resilience, and when used in angles, it can provide structural support and stability. This durability can ensure that the structure remains visually appealing for years to come, without compromising on safety or integrity. Overall, steel angles play a significant role in the aesthetic of a structure, adding a sense of modernity, strength, and versatility. Their clean lines, dynamic shapes, and durability can all contribute to creating a visually appealing and impactful architectural design.

- Q: What is the maximum deflection allowed for a steel angle?

- The maximum deflection allowed for a steel angle depends on various factors such as the size, shape, and type of steel angle being used, as well as the specific application and design requirements. The deflection limit is typically determined based on engineering standards and codes, which outline the maximum acceptable deflection to ensure structural integrity and safety. In general, steel angles are designed to withstand different loads and stresses, and their allowable deflection is determined based on these factors. Engineers calculate the maximum allowable deflection to ensure that the angle can safely support the applied loads without experiencing excessive deformation or failure. To determine the maximum deflection allowed for a specific steel angle, one needs to refer to the design standards and specifications provided by professional engineering organizations, such as the American Institute of Steel Construction (AISC) or relevant building codes. These documents outline the maximum allowable deflection limits based on the specific parameters of the steel angle, such as its dimensions, material properties, and intended use. It is crucial to consult the appropriate design standards and codes to ensure compliance with safety regulations and to guarantee the structural integrity of the steel angle in its intended application.

- Q: Can steel angles be used in HVAC ductwork installations?

- Indeed, steel angles have the capability to be utilized in HVAC ductwork installations. In the realm of ductwork systems, steel angles are frequently employed to furnish the necessary support and stability. Their typical function involves acting as brackets or supports, securing the ducts firmly in position and preventing undesirable sagging or collapsing caused by the weight of the air conditioning or heating equipment. Given their robustness and durability, steel angles are well suited to withstand the forces and vibrations inherent in HVAC systems. Moreover, the ease with which steel angles can be welded or bolted together allows for a secure and stable installation. To summarize, steel angles are an exceedingly reliable and widely utilized element in HVAC ductwork installations.

- Q: How do steel angles contribute to the sustainability of a project?

- Steel angles contribute to the sustainability of a project in several ways. Firstly, they are made from recycled steel, reducing the demand for new raw materials and promoting a circular economy. Secondly, steel angles have a high strength-to-weight ratio, allowing for lighter and more efficient structural designs, which in turn reduces the amount of steel required and minimizes the carbon footprint of the project. Lastly, steel angles are durable, resistant to corrosion, and have a long lifespan, ensuring the longevity and sustainability of the structure they support.

- Q: How do you store and transport steel angles?

- Steel angles can be stored by stacking them horizontally on a flat and level surface, ensuring they are supported evenly to prevent deformation. To transport steel angles, they can be loaded onto flatbed trucks or trailers, securely strapped or chained to prevent movement during transit. Alternatively, they can be bundled together and lifted by cranes or forklifts, ensuring proper balancing and securing the bundle for safe transportation.

- Q: How do steel angles contribute to the energy efficiency of a building?

- There are multiple ways in which steel angles can enhance the energy efficiency of a building. To begin with, steel angles are commonly utilized as structural components during the construction of buildings. Their presence provides strength and support to the building's framework, enabling the incorporation of larger windows and open floor plans. This facilitates the entry of natural daylight, thereby diminishing the need for artificial lighting during the daytime and subsequently reducing energy usage. Moreover, steel angles have the ability to contribute to the creation of energy-efficient building envelopes. By integrating steel angles into the construction of walls, roofs, and floors, the occurrence of thermal bridging can be minimized. Thermal bridging refers to the escape or entry of heat in a building due to materials with high thermal conductivity, such as concrete or wood. By utilizing steel, which possesses low thermal conductivity, the transfer of heat is reduced, leading to an improvement in the overall thermal performance of the building envelope. Furthermore, steel angles can be employed for the installation of energy-conserving systems and equipment. For example, they can provide support for solar panels, which generate clean and renewable energy. Additionally, steel angles can be utilized in the installation of HVAC systems, promoting efficient air circulation and distribution throughout the building. By incorporating steel angles into these applications, the energy efficiency of the building is enhanced, resulting in decreased energy consumption and lower utility bills. To summarize, the utilization of steel angles significantly contributes to the promotion of energy efficiency in buildings. They provide structural integrity, help minimize thermal bridging, and support the installation of energy-conserving systems. By incorporating steel angles into the design and construction of a building, energy consumption is reduced, resulting in a more sustainable and cost-effective built environment.

- Q: Can steel angles be used for manufacturing furniture?

- Yes, steel angles can be used for manufacturing furniture. Steel angles are versatile and durable, making them suitable for various applications including furniture manufacturing. They can be used to create strong and sturdy frames, legs, and supports for different types of furniture such as tables, chairs, shelves, and cabinets. Steel angles are known for their strength and structural integrity, making them an excellent choice for furniture that needs to withstand heavy loads or have a long lifespan. Additionally, steel angles can be easily welded, cut, and shaped to fit specific design requirements, allowing for customization and creativity in furniture manufacturing.

- Q: How do you prevent steel angles from vibrating?

- There are several ways to prevent steel angles from vibrating: 1. Damping materials: Applying damping materials such as rubber pads, neoprene, or foam between the steel angles and the structure they are attached to can help absorb and dissipate vibrations. 2. Structural modifications: Reinforcing the steel angles by adding additional supports or bracing can help reduce vibrations. By increasing the stiffness and rigidity of the structure, the tendency for vibrations to occur can be minimized. 3. Mass modification: Adding additional mass to the steel angles can help stabilize them and reduce vibrations. This can be achieved by attaching weight plates or heavier components to the angles. 4. Tensioning: Applying tension to the steel angles can help reduce vibrations by increasing their natural frequency and stiffness. This can be done by tightening bolts or using tensioning devices. 5. Vibration isolation: Using vibration isolation techniques, such as mounting the steel angles on rubber isolators or spring mounts, can help isolate them from the surrounding structure and minimize vibration transmission. 6. Resonance avoidance: Identifying and avoiding the natural frequencies of the steel angles is crucial in preventing vibrations. By analyzing the structural dynamics and adjusting the design or operational conditions, resonance can be avoided, reducing the chances of vibrations. 7. Regular maintenance: Regularly inspecting and maintaining the steel angles can help identify any issues or potential sources of vibrations. This includes checking for loose connections, corrosion, or any signs of wear and tear that could contribute to vibration problems. It is important to note that the specific method(s) chosen to prevent steel angles from vibrating will depend on various factors, including the application, structural design, and environmental conditions. Consulting with a structural engineer or vibration specialist is recommended to ensure the most effective and appropriate solution is implemented.

- Q: What are the advantages of using steel angles?

- There are several advantages of using steel angles. Firstly, steel angles provide excellent structural support due to their high strength and durability. They can withstand heavy loads and extreme weather conditions, making them ideal for construction projects. Additionally, steel angles are versatile and can be easily fabricated, cut, and welded to meet specific design requirements. They are also cost-effective, as they have a long lifespan and require minimal maintenance. Lastly, steel angles offer great aesthetic appeal, making them a popular choice for architectural applications.

- Q: What is the maximum temperature that steel angles can withstand?

- The grade of steel utilized determines the maximum temperature that steel angles can tolerate. Typically, low carbon steel angles can endure temperatures of 600-700 degrees Celsius (1112-1292 degrees Fahrenheit) before their mechanical attributes start to decline. Nevertheless, higher carbon steels, stainless steels, or alloy steels have the capacity to withstand elevated temperatures, which may range from 800-1200 degrees Celsius (1472-2192 degrees Fahrenheit) or possibly even higher. It is crucial to refer to the specific material specifications or seek guidance from a materials engineer to ascertain the maximum temperature that a specific steel angle can withstand in a given application.

Send your message to us

Hot Rolled Steel Bar Equal Bar Unequal Bar SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords