Hot Rolled Flat Steel Bars SS400

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Flat Steel Bars SS400 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Flat Steel Bars SS400 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Steel Bars SS400 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: SS400

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Chemical composition of Q235

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Physical properties of Q235

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What’s the Processes Flow of Flat Steel Bars?

A3:The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

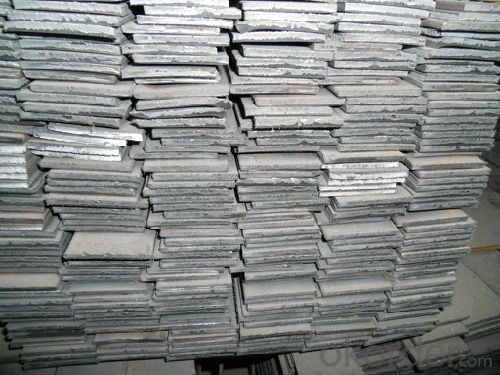

Images:

- Q: Can steel flat bars be used for making brackets or supports for HVAC ductwork?

- Yes, steel flat bars can be used for making brackets or supports for HVAC ductwork. Steel flat bars are commonly utilized in construction and engineering projects due to their durability and strength. When used as brackets or supports for HVAC ductwork, steel flat bars provide stability and rigidity, ensuring that the ducts are securely held in place. Additionally, steel flat bars can be easily cut, shaped, and welded to meet specific requirements, making them a versatile choice for fabricating brackets or supports.

- Q: How do steel flat bars perform in extreme weather conditions?

- Steel flat bars are known for their exceptional strength and durability, which makes them highly resistant to extreme weather conditions. They are capable of withstanding high temperatures, heavy rain, snow, and even strong winds. In extreme heat, steel flat bars have a high melting point, which means they can withstand prolonged exposure to intense heat without warping or losing their structural integrity. This makes them ideal for applications in areas with high temperatures, such as deserts or industrial settings. During heavy rain or snowfall, steel flat bars are highly resistant to corrosion and do not rust easily. This makes them suitable for outdoor applications where they may be exposed to moisture for extended periods. Moreover, their smooth surface allows water to run off easily, preventing the accumulation of water and reducing the risk of damage caused by freezing and thawing cycles. In areas prone to strong winds or storms, steel flat bars are known for their exceptional strength and stability. They can withstand high wind pressures and resist bending or breaking, making them a reliable choice for structures such as fences, barriers, and support beams. However, it is important to note that even though steel flat bars are highly resistant to extreme weather conditions, they still require proper maintenance to ensure their longevity. Regular cleaning, inspection, and applying protective coatings can help prevent any potential damage or deterioration caused by weathering. Overall, steel flat bars are a reliable choice for applications in extreme weather conditions due to their strength, durability, and resistance to corrosion.

- Q: Are steel flat bars available in different colors?

- No, steel flat bars are typically not available in different colors. They are usually sold in their natural steel color, which is a metallic grey or silver shade.

- Q: Can steel flat bars be anodized?

- No, steel flat bars cannot be anodized. Anodizing is a process primarily used on aluminum and its alloys to create a protective oxide layer on the surface. This process involves immersing the metal in an electrolyte solution and passing an electric current through it, causing oxygen ions to bond with the metal and form the protective layer. Steel, on the other hand, is mainly composed of iron and does not form the same type of oxide layer as aluminum during anodizing.

- Q: Can steel flat bars be used for making machine parts?

- Yes, steel flat bars can be used for making machine parts. Steel flat bars are commonly used in the manufacturing industry for a variety of applications, including the production of machine parts. They offer several advantages, such as high strength, durability, and versatility. Steel flat bars can be easily machined, welded, and shaped to meet specific requirements, making them a suitable choice for various machine components. Additionally, their uniform thickness and straight edges provide stability and precision in the manufacturing process. Therefore, steel flat bars are an excellent option for constructing machine parts.

- Q: Can steel flat bars be used for manufacturing tools or machinery?

- Yes, steel flat bars can be used for manufacturing tools or machinery. They are commonly used in various industries due to their strength, durability, and versatility. Steel flat bars can be easily shaped, welded, and machined according to specific requirements, making them a suitable choice for fabricating different types of tools or machinery components.

- Q: Are steel flat bars suitable for manufacturing machinery components?

- Yes, steel flat bars are suitable for manufacturing machinery components due to their high strength, durability, and versatility. They can be easily shaped, welded, and machined to meet specific requirements, making them an ideal choice for constructing various machinery components such as brackets, supports, frames, and bases. Additionally, their excellent resistance to corrosion and ability to withstand heavy loads make them reliable and long-lasting in demanding industrial environments.

- Q: How do steel flat bars perform in high-pressure applications?

- Steel flat bars are known for their exceptional strength and durability, making them a reliable choice for high-pressure applications. The structural integrity of steel allows it to withstand immense pressure without deformation or failure. This makes steel flat bars ideal for use in industries such as construction, manufacturing, and engineering, where high-pressure conditions are often encountered. Steel flat bars possess excellent mechanical properties, including high tensile strength and stiffness. These properties enable them to effectively resist the forces exerted by high pressure, ensuring their performance remains consistent under demanding conditions. Additionally, steel flat bars have a high resistance to corrosion, which is crucial in high-pressure applications where exposure to moisture or corrosive substances is common. Furthermore, steel flat bars can be fabricated and shaped into various forms to suit specific high-pressure requirements. They can be easily cut, welded, and bent, allowing for customization and adaptability in diverse applications. This versatility ensures that steel flat bars can be tailored to specific design needs and can effectively handle the pressures encountered. In conclusion, steel flat bars are well-suited for high-pressure applications due to their exceptional strength, durability, resistance to corrosion, and versatility in fabrication. Their ability to withstand immense pressure without compromising performance makes them an excellent choice for a wide range of industries that operate under high-pressure conditions.

- Q: What are the standard tolerances for width and thickness in steel flat bars?

- The standard tolerances for width and thickness in steel flat bars can vary depending on the specific industry or application requirements. However, there are generally accepted tolerances that are commonly used. For width, the standard tolerances typically range between +/- 0.005 to 0.030 inches, or +/- 0.13 to 0.76 millimeters. These tolerances ensure that the width of the steel flat bar remains within a specified range, allowing for consistency in manufacturing and ensuring that the final product meets the required dimensions. Regarding thickness, the standard tolerances for steel flat bars again depend on the specific application. However, a common tolerance range for thickness is typically between +/- 0.010 to 0.060 inches, or +/- 0.25 to 1.52 millimeters. These tolerances ensure that the thickness of the steel flat bar remains within a specified range, allowing for uniformity in production and ensuring that the final product meets the required thickness requirements. It is important to note that these tolerances are generalized and may vary depending on the specific industry or application. It is always recommended to consult the relevant industry standards or specifications to determine the precise tolerances required for a particular steel flat bar application.

- Q: What are the different types of surface finishes available for steel flat bars?

- There are several types of surface finishes available for steel flat bars, including mill finish, hot rolled, cold rolled, galvanized, and polished.

Send your message to us

Hot Rolled Flat Steel Bars SS400

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords