Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar

Details of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar

Name | Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | A36, Q235, Q195, SS400, St37-2 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 1.8mm-17.75mm |

steel flat bar width | 10mm-870mm |

steel flat bar length | 6m, 9m, 12m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Specification of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar

Width | Thickness | Length | Theoretical Weight |

(mm) | (mm) | (m) | (kg/m) |

20 | 2 | 6/9/12 | 0.31 |

20 | 2.5 | 6/9/12 | 0.39 |

20 | 2.75 | 6/9/12 | 0.43 |

25 | 2.5 | 6/9/12 | 0.49 |

25 | 3.75 | 6/9/12 | 0.74 |

30 | 2.5 | 6/9/12 | 0.59 |

30 | 3.5 | 6/9/12 | 0.82 |

30 | 9.75 | 6/9/12 | 2.3 |

40 | 3.5 | 6/9/12 | 1.1 |

40 | 4.75 | 6/9/12 | 1.5 |

40 | 11.75 | 6/9/12 | 3.69 |

50 | 2.75 | 6/9/12 | 1.08 |

50 | 4.5 | 6/9/12 | 1.77 |

50 | 9.75 | 6/9/12 | 3.83 |

60 | 5.5 | 6/9/12 | 2.6 |

60 | 7.5 | 6/9/12 | 3.53 |

60 | 11.5 | 6/9/12 | 5.42 |

80 | 5.5 | 6/9/12 | 3.45 |

80 | 7.5 | 6/9/12 | 4.71 |

80 | 11.75 | 6/9/12 | 7.38 |

100 | 3.25 | 6/9/12 | 2.55 |

100 | 4.75 | 6/9/12 | 3.73 |

100 | 7.5 | 6/9/12 | 5.89 |

120 | 9.75 | 6/9/12 | 9.18 |

120 | 11.75 | 6/9/12 | 11.07 |

150 | 9.75 | 6/9/12 | 11.48 |

150 | 11.5 | 6/9/12 | 13.54 |

150 | 13.5 | 6/9/12 | 15.9 |

160 | 11.75 | 6/9/12 | 14.76 |

200 | 9.5 | 6/9/12 | 14.92 |

250 | 5.75 | 6/9/12 | 11.28 |

340 | 7.75 | 6/9/12 | 20.68 |

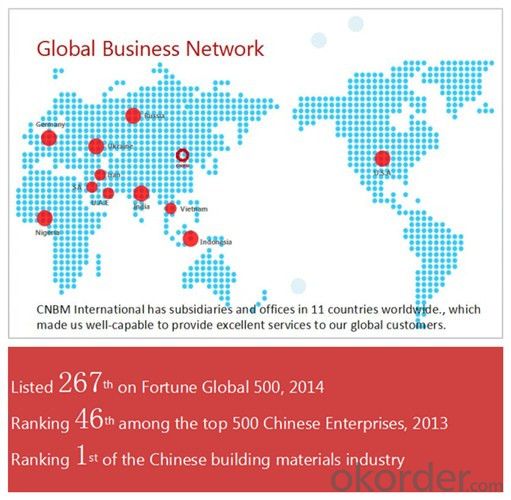

CNBM Introduction of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Supplier

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

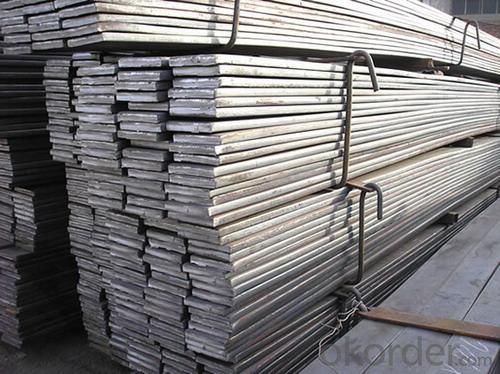

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different welding techniques used for special steel?

- Some of the different welding techniques used for special steel include TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and submerged arc welding. TIG welding is commonly used for stainless steel and allows for precise control and high-quality welds. MIG welding is versatile and can be used for a wide range of steel types, including special steel, providing fast and efficient welds. Submerged arc welding is used for thicker sections of special steel and offers excellent penetration and deposition rates.

- Q: How does special steel perform in high-pressure and high-temperature environments?

- Special steel performs exceptionally well in high-pressure and high-temperature environments due to its unique composition and properties. It exhibits excellent strength, toughness, and resistance to corrosion, making it ideal for withstanding extreme conditions. Additionally, special steel can maintain its mechanical properties, structural integrity, and dimensional stability even under intense heat and pressure, ensuring reliable performance and longevity in such environments.

- Q: What are the different types of mold steel?

- There are several different types of mold steel, including P20, H13, S7, and 420 stainless steel. Each type has its own unique properties and is used for specific applications in mold making and injection molding processes. P20 is a versatile mold steel that offers good machinability and wear resistance. H13 is a hot work tool steel known for its high heat resistance and toughness. S7 is a shock-resistant mold steel suitable for applications requiring high impact resistance. 420 stainless steel is corrosion resistant and commonly used for molds that require good polishing and texturing.

- Q: How does corrosion-resistant steel protect against chemical attacks?

- Corrosion-resistant steel protects against chemical attacks by forming a protective layer on its surface, which acts as a barrier between the steel and the corrosive substances. This layer, typically composed of chromium oxide, is highly stable and prevents the steel from direct contact with chemicals, thus reducing the likelihood of corrosion.

- Q: What are the main applications of special steel in the power generation sector?

- Special steel is extensively used in the power generation sector for various critical applications. Some of the main applications include turbine blades, rotors, and casings, which require high strength, heat resistance, and corrosion resistance. Additionally, special steel is used in the construction of power plant boilers, pressure vessels, and piping systems, ensuring efficient operation and long-term durability. Furthermore, it finds application in the manufacturing of electrical components such as generators, transformers, and transmission lines, where its superior electrical conductivity and magnetic properties are crucial. Overall, special steel plays a vital role in enhancing the performance, reliability, and safety of power generation equipment and infrastructure.

- Q: What is the fatigue strength of special steel?

- The fatigue strength of special steel refers to its ability to withstand repeated loading and unloading without failure. It is typically higher than that of regular steel due to its enhanced composition and manufacturing process, which makes it more resistant to fatigue and allows it to endure higher stress levels.

- Q: Can special steel be used in high-pressure applications?

- Yes, special steel can indeed be used in high-pressure applications. Special steels, also known as alloy steels, are specifically designed to have enhanced mechanical properties such as high strength, ductility, and corrosion resistance. These properties make them suitable for withstanding high-pressure environments. Special steels are commonly used in industries such as oil and gas, aerospace, automotive, and power generation, where high-pressure applications are encountered. For example, in the oil and gas industry, special steels are used to manufacture high-pressure pipelines, valves, and pressure vessels that can withstand the extreme pressure conditions during oil drilling, transportation, and refining processes. The high strength of special steel allows it to withstand the internal pressure exerted by fluids or gases without deformation or failure. Additionally, its corrosion resistance properties ensure that the steel remains intact and free from damage caused by the harsh operating conditions often associated with high-pressure applications. Moreover, special steels can be tailored to meet specific requirements by adjusting their chemical composition and heat treatment processes. This customization allows the steel to exhibit even higher strength, toughness, and resistance to fatigue, making it ideal for applications involving high-pressure environments. In summary, special steel can be used in high-pressure applications due to its enhanced mechanical properties and corrosion resistance. Its ability to withstand extreme pressures makes it a reliable choice for various industries where high-pressure conditions are encountered.

- Q: How does special steel perform in cryogenic conditions?

- Special steel performs well in cryogenic conditions. Its low temperature resistance allows it to maintain its strength, toughness, and ductility even at extremely cold temperatures. This makes it suitable for various applications in cryogenic industries, such as liquefied natural gas (LNG) storage tanks, aerospace components, and medical equipment. Additionally, special steel's resistance to brittleness and corrosion ensures its reliability and durability in these challenging environments.

- Q: How does special steel perform in terms of wear resistance in abrasive environments?

- Special steel is known for its exceptional wear resistance in abrasive environments. The unique composition and heat treatment processes used in the production of special steel result in a higher hardness level compared to standard steels. This increased hardness makes special steel highly resistant to wear caused by abrasive particles or surfaces. In abrasive environments where friction and contact with hard materials are prevalent, special steel exhibits excellent performance. It can withstand the erosive effects of abrasive particles, such as sand, rocks, or metal fragments, without significant wear or damage. This durability makes special steel an ideal choice for various applications, including mining equipment, cutting tools, industrial machinery, and automotive components. Moreover, the wear resistance of special steel is not only limited to its surface but also extends throughout its structure. This means that even if the surface of the steel is scratched or abraded, the underlying material remains highly resistant to wear. This characteristic ensures a prolonged lifespan of components made from special steel, reducing maintenance costs and downtime. Furthermore, special steel can maintain its wear resistance even under high temperatures. This property is particularly advantageous in abrasive environments where friction-induced heat can accelerate wear. The ability of special steel to retain its hardness and wear resistance at elevated temperatures ensures its effectiveness in demanding applications like high-speed machining or hot forging. Overall, special steel outperforms standard steels in terms of wear resistance in abrasive environments. Its superior hardness, structural integrity, and temperature resistance make it an excellent choice for applications where durability and longevity are essential.

- Q: What are the challenges faced in the manufacturing process of special steel?

- The manufacturing process of special steel involves numerous challenges that need to be addressed to ensure the production of high-quality steel. Some of the main challenges faced in this process are: 1. Raw material selection: Special steels require specific alloying elements in precise proportions to achieve desired properties. Choosing the right raw materials is crucial, as it directly impacts the quality of the final product. Ensuring consistent availability and quality of these raw materials can be a challenge. 2. Alloy design and composition: Designing the alloy composition to meet specific requirements can be complex. Achieving the desired balance of strength, hardness, toughness, corrosion resistance, and other properties requires thorough research, testing, and expertise. Developing new alloys with improved properties can be particularly challenging. 3. Melting and refining: Special steels are typically produced through electric arc furnaces or induction melting. Maintaining precise temperature control, proper cooling rates, and refining processes to eliminate impurities like sulfur, phosphorus, and non-metallic inclusions are crucial. These steps require advanced technology and precise control to ensure consistent quality. 4. Heat treatment: Heat treatment is a critical step in the manufacturing process of special steel. Achieving the desired microstructure and properties through processes like quenching, tempering, annealing, or precipitation hardening can be challenging. Proper temperature control, heating and cooling rates, and time durations are essential for obtaining the desired properties. 5. Quality control and testing: Ensuring consistent quality throughout the manufacturing process is paramount. Regular testing and inspection to detect and eliminate defects, inconsistencies, and non-conformities are necessary. This includes dimensional accuracy, mechanical properties testing, non-destructive testing, and chemical analysis. 6. Production efficiency: Special steel manufacturing often involves complex procedures and longer processing times compared to regular steel production. Optimizing the production process to maximize efficiency, minimize waste, and reduce energy consumption is a constant challenge. Implementing lean manufacturing principles and utilizing advanced technologies can help address these challenges. 7. Environmental considerations: Manufacturing special steel can have a significant environmental impact. Addressing issues like energy consumption, waste management, emissions control, and water usage is essential for sustainable production. Compliance with environmental regulations and adopting eco-friendly practices can be challenging yet necessary. Overcoming these challenges requires a combination of technical expertise, research and development, investment in advanced equipment and technologies, and an ongoing commitment to quality control and process improvement.

Send your message to us

Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords