Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue

Details of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue

Name | Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | A36, Q235, Q195, SS400, St37-2 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 1.8mm-17.75mm |

steel flat bar width | 10mm-870mm |

steel flat bar length | 6m, 9m, 12m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Specification of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue

Width | Thickness | Length | Theoretical Weight |

(mm) | (mm) | (m) | (kg/m) |

20 | 2 | 6/9/12 | 0.31 |

20 | 2.5 | 6/9/12 | 0.39 |

20 | 2.75 | 6/9/12 | 0.43 |

25 | 2.5 | 6/9/12 | 0.49 |

25 | 3.75 | 6/9/12 | 0.74 |

30 | 2.5 | 6/9/12 | 0.59 |

30 | 3.5 | 6/9/12 | 0.82 |

30 | 9.75 | 6/9/12 | 2.3 |

40 | 3.5 | 6/9/12 | 1.1 |

40 | 4.75 | 6/9/12 | 1.5 |

40 | 11.75 | 6/9/12 | 3.69 |

50 | 2.75 | 6/9/12 | 1.08 |

50 | 4.5 | 6/9/12 | 1.77 |

50 | 9.75 | 6/9/12 | 3.83 |

60 | 5.5 | 6/9/12 | 2.6 |

60 | 7.5 | 6/9/12 | 3.53 |

60 | 11.5 | 6/9/12 | 5.42 |

80 | 5.5 | 6/9/12 | 3.45 |

80 | 7.5 | 6/9/12 | 4.71 |

80 | 11.75 | 6/9/12 | 7.38 |

100 | 3.25 | 6/9/12 | 2.55 |

100 | 4.75 | 6/9/12 | 3.73 |

100 | 7.5 | 6/9/12 | 5.89 |

120 | 9.75 | 6/9/12 | 9.18 |

120 | 11.75 | 6/9/12 | 11.07 |

150 | 9.75 | 6/9/12 | 11.48 |

150 | 11.5 | 6/9/12 | 13.54 |

150 | 13.5 | 6/9/12 | 15.9 |

160 | 11.75 | 6/9/12 | 14.76 |

200 | 9.5 | 6/9/12 | 14.92 |

250 | 5.75 | 6/9/12 | 11.28 |

340 | 7.75 | 6/9/12 | 20.68 |

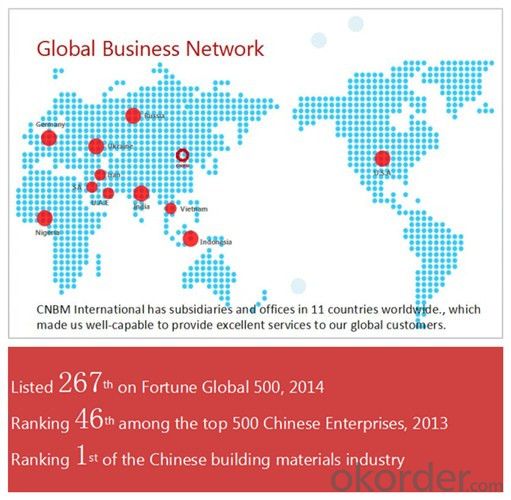

CNBM Introduction of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

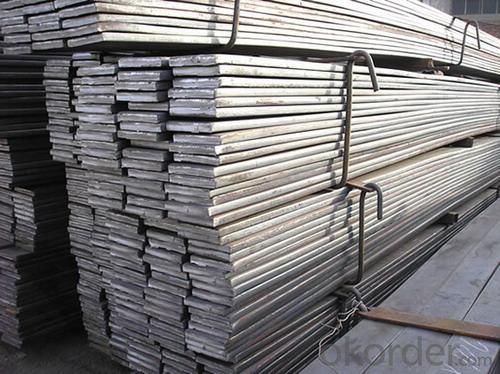

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel perform in cryogenic ductility?

- Special steel exhibits excellent performance in terms of cryogenic ductility. Cryogenic ductility refers to a material's ability to retain its strength and flexibility even at extremely low temperatures. Special steels are engineered specifically to endure harsh conditions, including cryogenic temperatures, making them suitable for applications such as LNG storage tanks, aerospace components, and superconductors. The composition of special steel is one of the key reasons for its exceptional cryogenic ductility. Generally, special steels are alloyed with elements like nickel, chromium, and molybdenum, which enhance their mechanical properties and resistance to low temperatures. These alloying elements provide the steel with increased strength, toughness, and resistance to brittle fracture, even in extremely cold environments. Moreover, special steels go through rigorous testing and quality control measures to ensure their performance in cryogenic conditions. This involves testing for parameters such as impact toughness, fracture toughness, and notch toughness, which are critical in assessing a material's ability to withstand brittle failure at low temperatures. Additionally, the manufacturing processes employed for special steel contribute to its excellent cryogenic ductility. Methods like vacuum induction melting and controlled cooling are often utilized to produce special steels. These techniques aid in eliminating impurities and improving the material's microstructure. This refined microstructure enhances the steel's ductility, enabling it to retain its mechanical properties even in cryogenic temperatures. In conclusion, special steel exhibits exceptional performance in terms of cryogenic ductility due to its meticulously designed composition, stringent testing, and advanced manufacturing processes. These factors make it a dependable and preferred choice for various industries that require materials capable of withstanding extreme cold conditions while maintaining strength and flexibility.

- Q: How does special steel contribute to the energy generation industry?

- Special steel plays a crucial role in the energy generation industry by contributing to the efficiency, reliability, and safety of various components and equipment used in power plants. One key area where special steel is essential is in the construction of turbine blades and generator rotors. These components are subjected to extreme temperatures, pressures, and mechanical stresses. Special steels, such as superalloys, are specifically designed to withstand these harsh conditions, ensuring the longevity and performance of these critical parts. By using special steel, power plants can operate at higher temperatures and pressures, leading to increased energy efficiency and power output. In addition to turbine components, special steel is also used in the construction of boilers and heat exchangers. These components are exposed to high temperatures and corrosive environments. Special steel alloys, such as stainless steels, are highly resistant to corrosion and can withstand the harsh conditions encountered in power plant operations. This corrosion resistance ensures the longevity and reliability of these components, reducing maintenance costs and downtime. Furthermore, special steel is utilized in the construction of transmission and distribution infrastructure. Steel cables and conductors are used to transmit electricity over long distances, and special steel alloys provide the necessary strength and conductivity for efficient power transmission. Additionally, steel is used in the construction of towers, poles, and other support structures, ensuring the stability and reliability of the electrical grid. Moreover, special steel is also vital in the production of nuclear energy. Nuclear power plants require materials that can withstand extreme temperatures, high radiation levels, and corrosive environments. Special steel alloys, such as stainless steels and nickel-based alloys, are specifically designed to meet these requirements, providing the necessary strength, resistance to radiation, and corrosion resistance for the safe and efficient operation of nuclear reactors. In summary, special steel is an integral part of the energy generation industry. Its unique properties and capabilities contribute to the efficiency, reliability, and safety of various components and equipment used in power plants. By using special steel, power plants can increase energy efficiency, reduce maintenance costs, and ensure the longevity and performance of critical infrastructure, ultimately supporting the sustainable and reliable generation of electricity.

- Q: How is wear-resistant stainless steel used in the production of cutting tools?

- Wear-resistant stainless steel is commonly used in the production of cutting tools due to its high hardness and resistance to wear and corrosion. This steel alloy is essential for making durable and long-lasting cutting tools, such as knives, blades, drills, and saws. The wear resistance of stainless steel ensures that these tools can withstand the friction and abrasion involved in cutting various materials, leading to improved performance and extended tool life.

- Q: What are the different surface cleaning methods for special steel?

- There are several surface cleaning methods that can be used for special steel to maintain its quality and appearance. 1. Mechanical Cleaning: This method involves the use of mechanical tools such as wire brushes, sandpaper, or abrasive pads to remove dirt, rust, or other contaminants from the surface of the steel. It is effective for removing loose particles and light stains but may not be suitable for deep stains or stubborn dirt. 2. Chemical Cleaning: Chemical cleaning is a common method used for special steel surfaces. It involves the use of specific chemical solutions that are applied to the surface to dissolve and remove contaminants. Different chemicals are used depending on the type of stain or dirt present. Acid-based cleaners are often used for rust removal, while alkaline cleaners are effective for removing grease or oil stains. 3. Electrochemical Cleaning: This method utilizes an electrical current to remove contaminants from the surface of the steel. It involves placing the steel in an electrolyte solution and applying a direct current, causing the contaminants to dissolve and separate from the surface. This method is effective for removing rust or corrosion but should be carefully monitored to prevent damage to the steel. 4. High-Pressure Water Cleaning: High-pressure water cleaning, also known as water blasting, involves the use of pressurized water to remove dirt, paint, or other contaminants from the steel surface. This method is effective for removing heavy stains or coatings and is commonly used in industrial cleaning processes. 5. Steam Cleaning: Steam cleaning is a non-abrasive method that utilizes high-temperature steam to loosen and remove dirt, grease, or other contaminants from the steel surface. It is a gentle method that can effectively clean delicate or sensitive surfaces without causing damage. It is important to note that the appropriate surface cleaning method for special steel depends on the specific type of steel, the nature of the contaminants, and the desired level of cleaning. It is recommended to consult with experts or follow manufacturer guidelines to ensure the best cleaning method is used for a particular type of special steel.

- Q: How does special steel contribute to the aerospace material weight reduction?

- Special steel contributes to aerospace material weight reduction by providing a lightweight yet strong and durable material option. Its unique properties, such as high strength-to-weight ratio and excellent corrosion resistance, allow for the construction of lighter aircraft components without compromising on safety or performance. This reduction in weight leads to improved fuel efficiency, increased payload capacity, and enhanced maneuverability, making special steel an essential element in aerospace industry's ongoing efforts to achieve greater fuel economy and sustainability.

- Q: What are the different types of precipitation-hardening steel?

- There are several different types of precipitation-hardening steel, including 17-4 PH, 15-5 PH, 13-8 PH, and 17-7 PH. These alloys are known for their ability to be strengthened through a precipitation hardening process, which involves a combination of heat treatment and aging. Each type of precipitation-hardening steel has its own unique composition and properties, making them suitable for various applications in industries such as aerospace, automotive, and medical.

- Q: What are the properties of corrosion-resistant alloy steel?

- Corrosion-resistant alloy steel possesses properties such as high resistance to rust, corrosion, and oxidation, making it suitable for applications in environments exposed to moisture, chemicals, or extreme temperatures. It typically contains elements like chromium, nickel, and molybdenum, which enhance its resistance to corrosion. Additionally, this type of steel is known for its durability, strength, and ability to maintain its integrity in challenging conditions.

- Q: How does the hardness of special steel affect its performance?

- The hardness of special steel plays a crucial role in determining its performance. The hardness of steel refers to its ability to resist indentation, scratching, or deformation during use. This property is directly related to the steel's microstructure and the amount of carbon present in it. When special steel is hardened, it undergoes a process called heat treatment, typically involving rapid cooling or quenching after being heated to high temperatures. This process alters the steel's microstructure, resulting in a harder material. The increased hardness provides several benefits to the performance of special steel. Firstly, a higher hardness level enhances the wear resistance of special steel. This is particularly important in applications where the steel is subjected to abrasive or erosive forces, such as cutting tools or machinery components. A harder steel can withstand these forces without significant wear or damage, resulting in improved longevity and reliability. Secondly, the hardness of special steel affects its strength and toughness. A harder steel generally exhibits higher strength, meaning it can withstand greater forces without permanent deformation or failure. This property is advantageous in applications where the steel is subjected to heavy loads or impacts. Additionally, a certain level of toughness is necessary to prevent brittle fractures. While high hardness can make a steel more brittle, careful heat treatment can balance the hardness and toughness, ensuring the steel remains strong and resistant to fracture. Furthermore, the hardness of special steel also affects its machinability. Hardened steel can be more challenging to machine due to its increased resistance to cutting tools. However, it offers greater dimensional stability and precision during machining operations, leading to more accurate and consistent results. In summary, the hardness of special steel significantly impacts its performance. A higher hardness level provides improved wear resistance, strength, and toughness, making it suitable for demanding applications. However, the balance between hardness and toughness needs to be carefully considered to avoid brittleness. Therefore, understanding and controlling the hardness of special steel is essential to optimize its performance in various industries.

- Q: How does special steel contribute to improved product performance?

- Special steel contributes to improved product performance by providing enhanced strength, durability, and resistance to wear and corrosion. It offers superior mechanical properties and can withstand extreme temperatures, pressures, and impacts. The use of special steel in manufacturing leads to longer-lasting products, improved efficiency, and enhanced safety. Additionally, its versatility allows for customization and innovation, enabling the creation of more advanced and high-performance products across various industries.

- Q: What are the applications of special steel in the agriculture sector?

- Special steel has numerous applications in the agriculture sector. It is used in the manufacturing of machinery and equipment such as plows, cultivators, and harvesters, due to its high strength and durability. Special steel is also utilized in the production of storage tanks and silos, providing protection against corrosion and ensuring the safety of agricultural products. Additionally, it is employed in the fabrication of irrigation systems, fencing, and animal enclosures, offering longevity and resistance to wear and tear. Overall, special steel plays a crucial role in improving productivity and efficiency in various agricultural operations.

Send your message to us

Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords