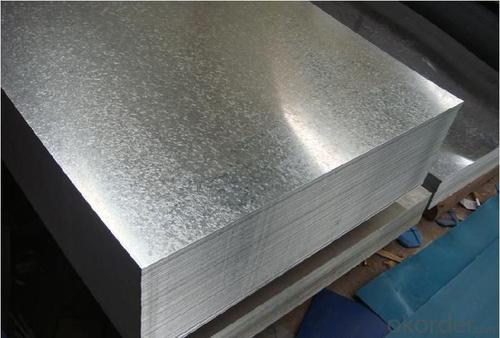

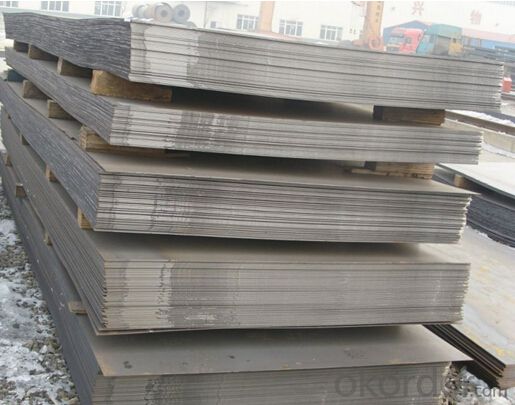

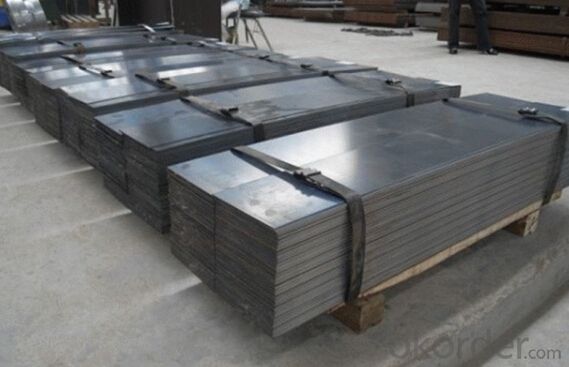

Hot Rolled Carbon Steel Plate Sheet Grade A36 SS400 ST37 Q235 S235JR

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Prime Hot Rolled Carbon Steel Plate_Sheet Grade A36_SS400_ST37_Q235_S235JR

Thickness:2mm-100mm

Width:1000-4000mm

MOQ: 3m.t.

Certificate: ISO, SGS

Specification of Hot Rolled Carbon Steel Plate_Sheet Grade A36_SS400_ST37_Q235_S235JR

Commodity | Prime hot rolled carbon steel plate / sheet dimensions |

Thickness | 0.6-200mm |

Width | 1000-4000mm |

Length | as custom's request |

Technique | Cold rolled or hot rolled mild steel plate |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS |

Material | T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570 |

Usage | Mechanical&manufacture,Steel strcuture,Shipbuilding,Bridging,Automobile chassis |

Terms of Payment | 30% T/T as deposit and 70% T/T balance againest B/L copy. |

Delivery Detail | Within 3-15 days after receipt of deposited for the mild steel plate |

CNBM Introduction of the Hot Rolled Carbon Steel Plate_Sheet Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of the Hot Rolled Carbon Steel Plate_Sheet

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the common challenges in welding titanium alloys?

- Welding titanium alloys poses several common challenges, mainly due to the unique properties of titanium. First, titanium has a high melting point, around 1668°C (3034°F), which requires specialized equipment and techniques to achieve optimal welding conditions. This high melting point also increases the risk of overheating and subsequent distortion or warping of the welded parts. Another challenge is the high reactivity of titanium with oxygen, nitrogen, and hydrogen. During the welding process, these gases can easily contaminate the weld pool, leading to the formation of brittle and porous welds. Therefore, stringent measures such as using inert shielding gases like argon or helium, maintaining a high level of cleanliness, and employing proper welding techniques like gas tungsten arc welding (GTAW) are necessary to minimize contamination and achieve sound welds. Titanium also has a strong affinity for carbon, which can result in the formation of brittle intermetallic compounds during welding. To prevent this, it is crucial to use low-carbon filler metals and ensure proper heat input to avoid carbon diffusion into the weld zone. Furthermore, titanium alloys have a low thermal conductivity, which means that heat generated during welding tends to concentrate in a small area, leading to localized overheating and potential damage. Therefore, controlling heat input and employing appropriate welding techniques to distribute heat evenly are crucial to avoid overheating and maintain the integrity of the welded joint. Lastly, titanium alloys exhibit a high thermal expansion coefficient, causing significant thermal expansion and contraction during the welding process. This can result in distortion and residual stresses in the welded parts. To mitigate these issues, preheating and post-weld heat treatment may be necessary to minimize distortion and relieve residual stresses. In summary, the common challenges in welding titanium alloys include high melting point, reactivity with gases, potential contamination, formation of intermetallic compounds, low thermal conductivity, and significant thermal expansion. By understanding these challenges and implementing appropriate welding techniques, it is possible to overcome these difficulties and achieve high-quality welds in titanium alloys.

- Q: How does special steel perform in molding applications?

- Special steel performs exceptionally well in molding applications due to its unique properties. It possesses high strength, excellent wear resistance, and superior heat resistance, making it highly suitable for withstanding the demanding conditions of molding processes. Special steel also offers excellent dimensional stability, ensuring precise and accurate moldings. Furthermore, its corrosion resistance helps to prolong the lifespan of the molds, reducing maintenance costs. Overall, special steel enhances the performance and efficiency of molding applications, resulting in high-quality and durable products.

- Q: What are the different methods for improving the magnetic properties of special steel?

- There are several methods for improving the magnetic properties of special steel, including annealing, alloying, and heat treatment. Annealing involves heating the steel to a specific temperature and then slowly cooling it, which helps to refine the grain structure and reduce magnetic losses. Alloying is another method, where specific elements like nickel or cobalt are added to the steel to enhance its magnetic properties. Heat treatment is also commonly used, involving controlled heating and cooling processes to alter the microstructure and improve magnetic performance.

- Q: What are the main applications of special steel in the chemical processing industry?

- Special steel is widely used in the chemical processing industry due to its unique properties and capabilities. Some of the main applications of special steel in this industry include the manufacturing of storage tanks, pipelines, and reactors. Special steel is resistant to corrosion, high temperatures, and chemical reactions, making it ideal for handling and storing various chemicals and substances. Additionally, special steel is also utilized in the construction of equipment used in the separation, purification, and filtration processes in chemical plants. Overall, the main applications of special steel in the chemical processing industry revolve around its durability, resistance to corrosion, and ability to withstand harsh chemical environments.

- Q: What is the significance of tensile strength in special steel?

- Tensile strength is of great significance in special steel because it determines the steel's ability to withstand stretching or pulling forces without breaking or deforming. This property is crucial in various industries, especially in manufacturing and construction, where high tensile strength is required for structural integrity and safety. Special steel with superior tensile strength can withstand heavy loads, resist impacts, and provide durability, making it highly sought after in applications such as building infrastructure, automotive manufacturing, and aerospace engineering.

- Q: Can special steel be used in cryogenic applications?

- Indeed, cryogenic applications can utilize special steel. In particular, austenitic stainless steels like 304 or 316 are frequently employed in cryogenic settings because of their remarkable mechanical attributes and ability to withstand low temperatures. These steels maintain their strength, toughness, and ductility even in exceedingly cold environments, rendering them suitable for cryogenic use. Furthermore, special steels also exhibit commendable resistance to corrosion and thermal expansion, which are crucial considerations in cryogenic applications. In summary, special steel alloys possess a distinctive combination of properties that make them highly suitable for withstanding and functioning in extremely frigid conditions.

- Q: How does special steel contribute to the renewable energy conversion efficiency?

- Special steel plays a crucial role in improving the renewable energy conversion efficiency by offering enhanced mechanical properties, corrosion resistance, and temperature resistance. It is used in the manufacturing of various renewable energy components such as wind turbine blades, solar panels, and hydroelectric power systems. The strength and durability of special steel ensure that these components can withstand harsh environmental conditions, resulting in increased efficiency, reliability, and lifespan. Additionally, special steel's high thermal conductivity allows for efficient heat transfer in concentrated solar power plants, further optimizing energy conversion.

- Q: What are the different types of corrosion that special steel can encounter?

- Special steel can encounter various types of corrosion, including general corrosion, localized corrosion such as pitting and crevice corrosion, galvanic corrosion due to the contact with dissimilar metals, intergranular corrosion along grain boundaries, and stress corrosion cracking caused by the combined effect of tensile stress and corrosive environment.

- Q: Can special steel be used in the computer manufacturing industry?

- Yes, special steel can be used in the computer manufacturing industry. It is commonly used for various applications such as computer casings, hard drive components, and heat sinks due to its strength, durability, and thermal conductivity properties.

- Q: How does special steel contribute to improving product safety?

- Special steel contributes to improving product safety in several ways. Firstly, special steel is known for its high strength and durability, making it ideal for manufacturing components that need to withstand extreme conditions or heavy loads. This ensures that products made with special steel are less likely to fail or break, reducing the risk of accidents or injuries. Secondly, special steel can be engineered to have specific properties such as corrosion resistance, fire resistance, or impact resistance. By incorporating these properties into the design and production of products, special steel enhances their safety features. For example, in the automotive industry, special steel is used to manufacture reinforced frames and safety components, providing better protection to passengers in case of collisions. Additionally, special steel is often used in critical applications where reliability and precision are paramount, such as medical equipment, aerospace components, or industrial machinery. The high performance and consistency of special steel ensure that these products function as intended, minimizing the chances of malfunctions or failures that could jeopardize safety. Overall, the use of special steel in various industries contributes to improving product safety by enhancing strength, durability, resistance to external factors, and reliability.

Send your message to us

Hot Rolled Carbon Steel Plate Sheet Grade A36 SS400 ST37 Q235 S235JR

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords