1、Structure of Hot Rolled Carbon Steel Plate Description:

Hot rolled carbon steel plate is widely used for automotive, truck frames, automotive wheels, pipe and tubular, water heaters, agriculture equipment, strappings, stampings, compressor shells, railcar components, wheel rims, metal buildings, railroad-hopper cars, doors, shelving, discs, guard rails, pipe and tubular, automotive clutch plates .Hot Rolled Sheet is used for a wide range of applications, from simple bends to complex draws or structural applications that require a specific strength level. The steel grade and processing technique of the metal are important in order to meet the customer requirements.

2、 Main Features of Hot Rolled Carbon Steel Plate:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

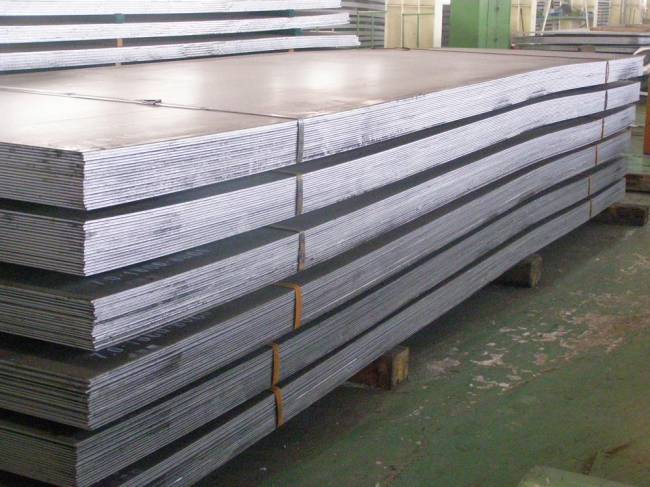

3、Hot Rolled Carbon Steel Plate Images:

4、Hot Rolled Carbon Steel Plate Specification:

Type | astm a36 steel plate/ A515 Gr.70 hot rolled steel plate and sheet |

Standard | ASTM A36/A36M, ASTM A20/A20M, JIS G3115,DIN 17100,EN 10028 |

Material | A36,A106Gr.B,Q235,Q345,Q195,ST37-2,ST52-3,A516-Gr.55/Gr60/Gr65, Gr70,A204,A378Gr.2/Gr.12/Gr22,13CrMo44,10CrMo910,15Mo3, A515 Cr.60/Cr55/Cr65,4140,4130 etc |

Dimension | Thickness: 0.4mm-280mm as customer's requirement |

Width: 1000mm,1219mm,1250mm,1500mm,1800mm,2000mm,2200mm, 2500mm,3000mm,as customer's requirement |

Length:2000mm,2438mm,3000mm,6000mm,as customer's requirement |

Surface | Clean, blasting and painting according to customer requirement |

Application | It is widely used in Building Construction,Bridge,Architecture,Vehicles Components,hipping,High pressure container,Boiler, Large Structure steel etc |

5、 FAQ of Hot Rolled Carbon Steel Plate:

①How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.

③ How can we get more information?

You can contact us by Email or call us directly and we will do our best to give you valuable information as much as possible but this service is not available on weekends.