All Categories

- - Steel Wire Rod

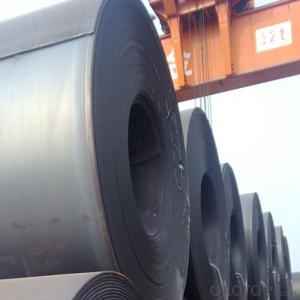

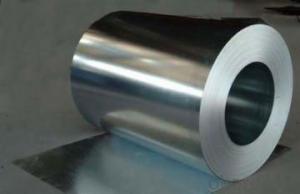

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

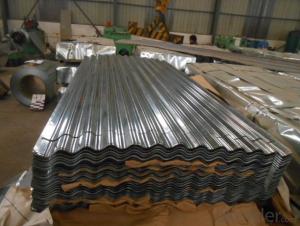

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel sheets involved in the development of industrial blast-resistant buildings?

Steel sheets are an essential component in the development of industrial blast-resistant buildings as they provide structural strength and durability. These sheets are used to construct the walls, roofs, and floors of these buildings, ensuring they can withstand the force generated by explosions. Steel sheets help distribute the blast energy and prevent the collapse of the building, offering protection to occupants and critical infrastructure within.

What is the role of steel sheets in the manufacturing of advanced materials for interstellar travel and cosmic exploration?

Steel sheets play a crucial role in the manufacturing of advanced materials for interstellar travel and cosmic exploration. These sheets are used in various components and structures, providing strength, durability, and protection against extreme conditions encountered in outer space. They form the foundation for constructing spacecraft, habitats, and equipment, ensuring their integrity and ability to withstand the harsh environment of space. With their high tensile strength and resistance to temperature fluctuations, steel sheets contribute to the advancement of technology and materials needed for interstellar travel and cosmic exploration.

How do you weld steel sheets together?

To weld steel sheets together, you need to first clean the surfaces to be joined, ensuring they are free from any dirt, grease, or rust. Then, position the sheets properly and clamp them securely to avoid any movement during the welding process. Next, choose the appropriate welding method such as MIG, TIG, or stick welding, depending on the thickness of the sheets and the desired weld quality. Adjust the welding machine settings according to the material thickness and type of joint. Start welding by creating a tack weld at one end of the joint and then proceed by welding along the entire seam, maintaining a consistent speed and angle. After completing the weld, allow it to cool down slowly to relieve any residual stress. Finally, inspect the weld for any defects and perform any necessary post-welding treatments like grinding or painting.

What are the different grades of steel used in sheet manufacturing?

There are several grades of steel commonly used in sheet manufacturing, including low carbon steel (mild steel), high carbon steel, stainless steel, galvanized steel, and aluminum. Each grade has different properties and characteristics that make them suitable for specific applications in sheet manufacturing.

Wholesale Steel Sheets from supplier in Greece

Whether you require Steel Sheets for construction, manufacturing, or other applications, we have a wide selection to meet your specific requirements. Our Steel Sheets are sourced from reputed manufacturers and are manufactured to international quality standards, ensuring reliability and durability.

We understand the importance of timely delivery and strive to provide efficient logistics solutions to ensure your Steel Sheets reach you on time. Our dedicated team of professionals is available to assist you with any queries or technical support you may require, from product selection to installation guidance.

At our company, customer satisfaction is our top priority. We believe in building long-term relationships with our clients based on trust, transparency, and quality. We are committed to providing competitive pricing without compromising on the quality of our products and services.

With our strong presence in the Greek market, we have developed a deep understanding of local regulations and industry trends. This enables us to provide you with valuable insights and recommendations to optimize your projects and achieve the desired outcomes.

Whether you are a small business or a large corporation, we are ready to cater to your Steel Sheets requirements in Greece. Contact us today to experience the efficiency, reliability, and excellence that sets us apart as a leading supplier of Steel Sheets in Greece.

We understand the importance of timely delivery and strive to provide efficient logistics solutions to ensure your Steel Sheets reach you on time. Our dedicated team of professionals is available to assist you with any queries or technical support you may require, from product selection to installation guidance.

At our company, customer satisfaction is our top priority. We believe in building long-term relationships with our clients based on trust, transparency, and quality. We are committed to providing competitive pricing without compromising on the quality of our products and services.

With our strong presence in the Greek market, we have developed a deep understanding of local regulations and industry trends. This enables us to provide you with valuable insights and recommendations to optimize your projects and achieve the desired outcomes.

Whether you are a small business or a large corporation, we are ready to cater to your Steel Sheets requirements in Greece. Contact us today to experience the efficiency, reliability, and excellence that sets us apart as a leading supplier of Steel Sheets in Greece.