All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the potential applications of cold-rolled steel in the emerging field of 3D printing?

Cold-rolled steel has the potential to be a game-changer in the emerging field of 3D printing. Its high strength and durability make it suitable for manufacturing industrial components, such as machinery parts, tools, and prototypes. Additionally, its excellent surface finish and dimensional accuracy make it a viable material for producing intricate and precise 3D-printed designs. The use of cold-rolled steel in 3D printing opens up possibilities for creating robust and functional objects, expanding the range of applications and advancing the capabilities of this innovative technology.

What is the relationship between cold-rolling and the malleability of steel?

Cold-rolling significantly improves the malleability of steel. Cold-rolling is a process in which steel is passed through rollers at room temperature, causing plastic deformation and reducing its thickness. This process aligns the crystal structure of the steel, making it more uniform and compact. As a result, the steel becomes more ductile and flexible, enhancing its malleability.

What are the considerations for using cold-rolled steel in architectural and artistic projects?

There are several considerations when using cold-rolled steel in architectural and artistic projects. Firstly, its smooth and polished surface makes it an ideal choice for aesthetic purposes, as it can be easily painted, coated, or left exposed for a modern and sleek appearance. Additionally, cold-rolled steel offers excellent strength and durability, ensuring the longevity of the project. Its dimensional accuracy and consistency enable precise fabrication and ease of installation. However, it is essential to consider the potential for corrosion, as cold-rolled steel is more susceptible to rust compared to hot-rolled steel. Adequate surface treatment, such as galvanizing or powder coating, should be applied to protect against environmental elements. Lastly, the cost of cold-rolled steel may be higher than other materials, so budget considerations should be taken into account when choosing it for architectural or artistic endeavors.

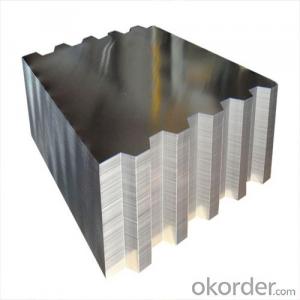

Wholesale Cold Rolled Steel from supplier in Greece

Our team of experts is committed to ensuring that you receive the highest quality Cold Rolled Steel products that meet your specific requirements. We understand the importance of timely delivery and cost-effectiveness, and strive to provide you with competitive prices and efficient logistics solutions.

Whether you are in the construction, automotive, or manufacturing industry, we have the Cold Rolled Steel products that will suit your needs. From sheets and coils to precision slitting and cutting services, we offer a wide range of options to cater to your exact specifications.

In addition to our product offerings, we also provide comprehensive technical support services. Our team is well-versed in the properties and applications of Cold Rolled Steel, and can offer valuable insights and recommendations to help you make informed decisions for your projects. We are here to assist you every step of the way, from product selection to post-sales support.

As part of the CNBM group, we have access to a global network of resources and expertise, which allows us to stay at the forefront of the industry and provide you with the latest advancements in Cold Rolled Steel technology. We continuously invest in research and development to ensure that our products meet the highest standards of quality and performance.

At our company, customer satisfaction is our top priority. We take pride in building long-term relationships with our clients, and are dedicated to providing you with exceptional service and support. Whether you require a small order or a large-scale project, we are committed to delivering excellence in every aspect of our business.

Contact us today to discuss your Cold Rolled Steel needs in Greece. Let us be your trusted partner for all your Cold Rolled Steel procurement requirements.

Whether you are in the construction, automotive, or manufacturing industry, we have the Cold Rolled Steel products that will suit your needs. From sheets and coils to precision slitting and cutting services, we offer a wide range of options to cater to your exact specifications.

In addition to our product offerings, we also provide comprehensive technical support services. Our team is well-versed in the properties and applications of Cold Rolled Steel, and can offer valuable insights and recommendations to help you make informed decisions for your projects. We are here to assist you every step of the way, from product selection to post-sales support.

As part of the CNBM group, we have access to a global network of resources and expertise, which allows us to stay at the forefront of the industry and provide you with the latest advancements in Cold Rolled Steel technology. We continuously invest in research and development to ensure that our products meet the highest standards of quality and performance.

At our company, customer satisfaction is our top priority. We take pride in building long-term relationships with our clients, and are dedicated to providing you with exceptional service and support. Whether you require a small order or a large-scale project, we are committed to delivering excellence in every aspect of our business.

Contact us today to discuss your Cold Rolled Steel needs in Greece. Let us be your trusted partner for all your Cold Rolled Steel procurement requirements.