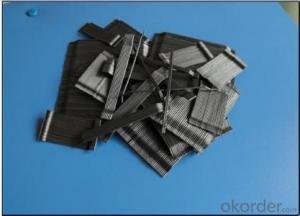

Hot dipped galvanized wire of good quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: Hi there,I have a very old house which only has 2 wires (1 white, 1 black) coming out of the wall.The ceiling fan / light has 2 red wires, 1 black, 1 green.What is right way to wire for this to operate?Thanks,

- Most fans have a wiring schematic and this will tell you how to wire it. Normally black is the power, green is a ground, which you don't have, and as for the red wires I'm not sure. Is this a new fan or one that has been used before. In the USA we have a white wire which is a neutral. I'm puzzled about the two red wires, these may have been added at a later date. If your in a country that has 240 volts then this may be an explanation. Regards, Dale

- Q: 1989 Honda Accord LxWhat is the wiring Diagram for the Stock stereo wiring harness?Just pulled out the old Stereo wanna put my deck in there now but i dont know the cars harness colorss.

- Check out a Chilton's manual for that car.It may be at your local library to view, not sure that they will let you check that out if they have it.Hopefully they have a color copying machine so that you could photo copy the schematic and take that with you.

- Q: The wire is size 10AWG and will be to install a small fluorescent light in a closet. It is coming off of a typical electric outlet. I know someone who is witing it with commercial wire and I think it may be dangerous. Is it?

- If wired properly, it would be much less dangerous than if wired with 16 or 18 gauge wire. The bigger the diameter of the wire, the more less the wire heats up and the less the chance of the wire overheating.

- Q: I have this ipod cord in my car to play music off of, and at first it started cutting out. I would move the wire in a specific spot to a position to where it would work. Then eventually it just stopped working all together, so im assuming the wires inside have been damaged. Now as i said before in a specific spot so im pretty positive i know where it is broken at, but ive never actually spliced a wire, or soldered before. This is where i need help. What tools and materials will i need to fix the wire? Also, how would i fix it? Thanks for the help in advance!

- The wires in those little patch cords and headphones and stuff are often very fine and hard to splice or solder. You could get you some wire cutters and wire strippers and a soldering iron and some electrical tape or shrink wrap and go at it, but it would probably be just as well to get another cord.

- Q: i would like to know what are the best spark plug wires

- For the money I like MSD. But it depends what they are going on. Older V8's you have lots of aftermarket options. Newer cars you are going to limited to the store you go to. More than likely the store will carry there brand and a more expensive name brand. You want the best you will pay more for it. Accell also makes good products and you can find them at most parts stores as well. 1. MSD 2. Accell

- Q: I have a 1997 Dodge Neon 2DR and i did a electric door and mirror conversion but i cannt figure out the wiring... how would i go about figuring it out... can some explain or better show me how a basic lock and mirror controls are wired

- i own a repair shop,and if you,ll get a good Haynes repair manual on it,this will have the wiring diagrams in it,for doing this ,that's about the only way you can wire it up right on this job,good luck,i hope this help,s.

- Q: when i wire these together the light stays on. help

- the black wires supplies power, the white is your safety. don't wire white and black together. on the fan you are installing, normally, one black gives power to the light ,the other to the fan. you must connect white to white and black to black. hope this helps

- Q: for california electrical code, am i limited to insert no more than one wire per knockout on a box ?

- no. the number of wires in the box is restricted based on the volume of the box but the number of wires entering a knock out is restricted by the size of the conduit or the cable type connected to the knock out.

- Q: If 46 m of nichrome wire is to have a resistance of 12.0 Ω at 20°C, what diameter wire should be used? in mm

- Resistance of a wire in Ω R = ρL/A ρ is resistivity of the material in Ω-m L is length in meters A is cross-sectional area in m? A = πr?, r is radius of wire in m resistivity Nichrome 150e-8 Ω-m 12 = (150e-8 Ω-m)(46m)/(πr?) solve for r, which would be the radius of the wire in meters. change to mm, and multiply by 2 to get diameter. .

- Q: The coiled wire is for making bucktails and i would like to buy it in bulk.

- I am not sure what bucktails are, but a good place to buy coils of wire is a hardware store or farm store. You should be able to get aluminum wire, galvanized wire, or mechanics wire (black/brown)

Send your message to us

Hot dipped galvanized wire of good quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches