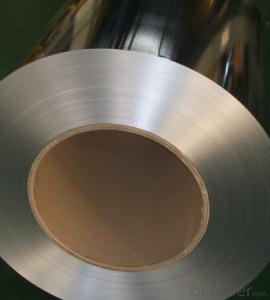

Hot Dipped Galvanized Steel Coils for construction CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Quick Details:

hot dipped galvanized steel coil

Material: | SGCC, DX51D+Z |

Thickness: | 0.13-0.8mm |

Width: | 750-1250mm |

Zinc coated: | 40-180g/m2 |

Standard: | ASTM,AISI,DIN,GB |

Spangle: | Zero Spangle, Regular Spangle, Small Spangle |

Surface treatment: | chromated and oiled, chromated and non-oiled |

Technique: | cold rolled galvanized |

Grade: | Prime |

ID: | 508mm or 610mm |

Coild weight: | 3-5MT/Coil or as your request |

Quality: | Softy , half hard and hard quality |

2.Packaging & Delivery

Packaging Details:Fully seaworthy export packing. Each coil is wrapped in water-proof paper.Fixed with steel strips.

Delivery Detail:about 12 days

3.Festure:

Certificate: | ISO9001, BV test |

MOQ: | 20MT |

Supply Ability: | 3000MT/month |

OEM: | Accept |

Price Item: | FOB, CFR, CIF |

4.Specification:

Standard | EN 10327 | DX51D+AZ, DX52D+AZ, DX53D+AZ, |

EN 10326 | SS250GD+AZ, SS350GD+AZ | |

JIS G3321 | SGLCC, SGLCD, SGLCDD, SGLC 400 | |

ASTM A792M | CS type C, CS type B, DS, SS255, SS345 | |

Base Metal | Cold rolled steel coils SPCC, SPCD, SPCE, DC01, DC03, DC04, CS, DS, DDS, Q195, Q250, Q350 | |

Thickness | 0.22mm-2.0mm | |

Width | 700mm-1300mm | |

Coil ID | 508mm, 610mm | |

Zinc coating | 60g/m2-180g/m2 | |

Surface treating | chromium free passivation, chromium passivation, fingerprint resistant, oiled | |

Spangle types | regular spangle | |

5.What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: What is the lifespan of steel coils?

- The lifespan of steel coils can vary depending on various factors such as the quality of the steel, its usage, maintenance, and environmental conditions. However, with proper care and maintenance, steel coils can typically last for several decades.

- Q: What are the dimensions of steel coils used in the electrical equipment industry?

- The dimensions of steel coils used in the electrical equipment industry can vary depending on the specific application and requirements of the equipment being manufactured. However, there are some common dimensions that are frequently used in this industry. Typically, the width of steel coils used in electrical equipment manufacturing ranges from 0.5 inches to 72 inches (1.27 cm to 182.88 cm). The thickness of these coils can vary from as thin as 0.005 inches (0.0127 cm) to as thick as 0.25 inches (0.635 cm). The length of steel coils used in the electrical equipment industry can also vary, but it is often determined by the manufacturing process and the specific equipment being produced. Coils can range from a few feet to several hundred feet in length. Furthermore, the weight of steel coils can vary depending on their dimensions and the type of steel being used. For instance, a common weight range for steel coils used in the electrical equipment industry is between 5,000 pounds (2,268 kg) and 50,000 pounds (22,680 kg). It is important to note that these dimensions are not fixed and can vary based on the specific needs of the electrical equipment industry. Manufacturers may have their own unique specifications and requirements for the steel coils they use in their products.

- Q: How are steel coils used in the production of bridges?

- Steel coils are used in the production of bridges as they are processed and shaped into various structural components like beams, plates, and girders. These coils are first uncoiled and then cut, rolled, and welded to create the required bridge sections. The high strength and durability of steel make it an ideal material for bridges, and the use of steel coils allows for efficient and precise manufacturing of these vital infrastructure elements.

- Q: Is it faster to smith steel or mithril in Rinescape assuming I'm going to mine everything myself?Mining level: 76Smithing level: 55

- i think steel would be better since there isn't a lot of mithril ore and it would take a lot of time to mine it and it will take also 4 coals to make a mith bar and 2 only for a steel bar

- Q: I am planning to buy a Walther P22. I have liked the Pistol's performance-superb.The only confusion that I have is about the Polymer Frame.Just for this I may shift to someother manufacturer.Are Polymer Frames better than Steel in durability and lifespan.Walther says YES.Any comments on this...Practical users...Thanks in advance

- All polymer frames are cast around steel 'skeleton' inserts, which bear the stress and wear between receiver slide, as well as other wear points. The great advantage to polymer frames is the lower weight over the polymer composite compared to an all-steel or other metal alloy receiver frame. As all wear contact points are 'steel-to-steel', the service life expectancy of a polymer-frame weapon will be the same as an all-steel frame design. NO polymer-frame design I know of has ANY stress or load contact points between metal and polymer-only surfaces. My polymer-frame H-K USP and my Glocks are constructed this way.

- Q: What are the dimensions of steel coils used in the mining equipment industry?

- The dimensions of steel coils used in the mining equipment industry can vary depending on the specific application and equipment. However, common dimensions for steel coils in this industry range from 0.5 to 3 millimeters in thickness and 600 to 2000 millimeters in width. The length can also vary but is typically around 1000 to 3000 meters.

- Q: Are steel coils used in appliances manufacturing?

- Yes, steel coils are commonly used in appliances manufacturing. They are widely used for constructing the frames, cabinets, and other structural components of various appliances such as refrigerators, washing machines, dishwashers, and ovens. Steel coils provide strength, durability, and stability to these appliances, making them an essential component in their manufacturing process.

- Q: Can steel coils be used in the production of HVAC systems?

- Yes, steel coils can be used in the production of HVAC (heating, ventilation, and air conditioning) systems. Steel coils are commonly used in the manufacturing of HVAC equipment such as air handlers, condenser coils, evaporator coils, and heat exchangers. Steel coils provide durability and strength, making them suitable for withstanding the high pressures and temperatures involved in HVAC operations. Additionally, steel coils offer good heat transfer properties, allowing for efficient heat exchange between the refrigerant and the air being conditioned. Overall, steel coils are a reliable and commonly used component in the production of HVAC systems.

- Q: How are steel coils used in the manufacturing of airbags?

- Steel coils are used in the manufacturing of airbags as they provide the necessary structural support and strength to ensure the airbags deploy effectively during a collision. The coils are typically placed within the airbag module to help maintain its shape and prevent it from collapsing on impact, ensuring the airbag can rapidly inflate to protect occupants in a vehicle.

- Q: What are the different methods of coil flattening for steel coils?

- There are several methods used for coil flattening in the steel industry. Some of the common methods include roller leveling, tension leveling, and stretcher leveling. Roller leveling involves passing the coil through a series of rollers to flatten it. Tension leveling uses a combination of tension and bending to remove any shape defects in the coil. Stretcher leveling stretches the coil in the lengthwise direction to eliminate any waviness or buckling. Each method has its own advantages and is used based on the specific requirements of the steel coil.

Send your message to us

Hot Dipped Galvanized Steel Coils for construction CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords