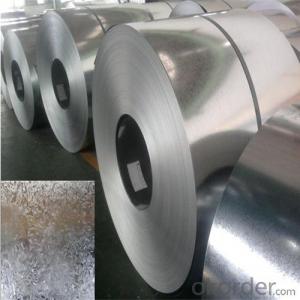

Hot Dipped Galvanized Steel Coil for Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:Hot Dipped Galvanized Steel Coil

Surface Treatment:Galvanized

Certification:ISO, SGS, BV, RoHS, IBR

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Roofing, Wall, Corrugated, Structure...

Edge:Mill

Stock:Stock

Steel Grade:Dx51d, SPCC, SGCC, CGCC, S350gd

Name:Hot Dipped Galvanized Steel Coil

Thickness:0.14-1.2mm

Width:600-1250mm

Surface:Oiled, Galvanized, Chromated

Zn Coating:40-275GSM

Spangle:Zero, Small, Big, Regular

Coil Weight:3-10tons

Coil ID:508/610mm

Certificate:BV, ISO

Test:QA-QC-Mtc

Export Markets:Global

Additional Info.

Packing:Standard Export Package

Standard:0.14-1.2mm*762-1250mm

HS Code:7905000000

Production Capacity:30000 Tons/Year

Product Description

1. Galvanized steel coil simple introduction:

Galvanized steel coil means that steel coils has gone through a chemical process

To keep it from corroding, so this protective metal, zinc layers, does not get rusty as easily. The coating also gives the steel a more durable, hard to scratch finish.

(1)Thickness:0.14-1.2mm

(2)Width:600-1250mm

(3)Material:SGCC,DX51D,S350GD,SPCC,CGCC

(4)Zn:40-275gsm

(5)Surface:oiled,chromated

(6)Application: Corrugated,Wall,Roofing,Structure and so on

2. Galvanized steel coil technical processing:

1)Uncoiled and sheared

2)Cleaned using a caustic solution, which can remove oil/grease, dirt, and paint

3)Entry looper to revised and then annealing furnace

4)Steel is dipped into the molten zinc bath

5)Cooled in a quench tank to reduce its temperature

6)Post treatment and crimper

3. Galvanized steel coil quality control:

Strict procurement process---skillful technical workers---final products inspection

(resistance to corrosion, salt spray test, exposure test, machinability, thermal resistance)

---standard packing

4. Galvanized steel coil advantages:

1)Zinc coating has good adhesion

2)Resistant to corrosive factors

3)High strength&quality

4)Strict quality control system

5)Standard export sea-worthy packing

5. Why choose us?

1).Advantages: We have two production line of PPGI and two lines for the galvanized steel coil, total yearly output is about 500000mt Also we have 56 professional salesperson from three international sales department, a group of technical engineers

And skillful quality control inspector.

2). Special technology support: We have two production line of pre-painted steel coil

And two lines for the galvanized steel coil, total yearly output is about 500000mt. In

Order to meet our customers new requirements, We also can manufacture the special

Products, such as Printed, Filmed, Pressed, Matte steel coil and the full hard G550

Galvanized steel and galvalume steel.

3). Conform the international quality standard: All products for export, according to the

International quality standard of Europe, Japan, Russia and America to produce.

- Q: What are the different methods of transporting steel coils?

- There are several methods of transporting steel coils, including using flatbed trucks, railcars, and ocean vessels. Flatbed trucks are commonly used for short distances and local deliveries, while railcars are utilized for longer distances and intermodal transportation. For international shipments, steel coils are typically transported on ocean vessels, either in containers or as breakbulk cargo. The choice of method depends on factors such as distance, destination, and cost-effectiveness.

- Q: What is the difference between black steel pipes and galvanized steel pipes when used for water or gas, and why?

- Black Steel or ductile steel pipes are made from scrap for the most part. Galvanized pipes are made from new raw materials and are electroplated to resist rust.

- Q: I am in the US and looking for a price on wide flange steel. I need a price of one W10x30 and 20 feet long.

- The price of steel is increasing daily, so an exact answer is rough. A W10x30 is a fairly common shape and shouldn't be too hard to find. For a very rough ballpark number, say $700/ton (installed price), the piece you require should be in the range of about $250.00 or less as I assume you'll be doing the installing. Please don't take this as the gospel, however. Price varies on location, stock, and availability. Open the phone book and contact your local steel supplier. Because the piece you require is fairly short, you might get lucky and find someone who has a waste piece that length that they will give you a good deal on. --------------------------------------... I just checked the AISC web site to verify the number I quoted above and they posted an article stating that the average mill price had just increased to over $1000/ton in May. The best advice I can provide at this point is to buy the W10 now and don't wait any longer.

- Q: I'm buying a new set of steel plugs.I've heard things about streched ears and cold weather not being to good. do you think it would be bad to be wearing steal plugs?

- I have never had a problem with mine in any weather. They may feel a little tighter if you are cold, but if it is uncomfortable, just take 'em out!

- Q: What are the different methods of stretch leveling steel coils?

- There are several methods of stretch leveling steel coils, including roller leveling, tension leveling, and temper rolling.

- Q: I bought a Remington 870 super mag last fall and wanted to to switch to non-tox steel loads. The gun came with a modified rem choke. I know that not all chokes are qualified to handle steel. It doesn't say anywhere on the choke no steel I was just wondering if anyone out there knew for sure that those chokes that the guns come with won't get damaged be steel.

- No problem. With steel shot you would use one choke size LARGER. If you want a full choke type pattern ( 70 % in a 30 inch circle at 30 yards ) you use a modified choke. if you want a modified pattern use the improved cylinder. Don't use the full or extra full. This is because when using lead shot it deforms, and fits through the choke, steel shot does not deform, it remains rigid. The first indication of a problem will be a slight bulge in the barrel right behind the choke. Check that once in a while, if you ever have that problem, it is not drastic if caught early. Today's modern shotguns all have been set up for steel shot. The old ones such as Belgium Brownings, are a no go. Funny thing, when we first began importing steel shot, I asked a Browning Tech guy if he thought I could fire steel out of my Belgium Browning. He said not a good idea, however, if you have the Citori or other Japanese made Brownings, no problem. Hummm, my expensive Brownings, no, but Japanese made OK, this is because the Japanese steel was higher quality. Geeeze. I was shocked.

- Q: Why is steel a stiff material?I'm doing a project on the use of steel in the construction of skyscrapers - and obviously, for the inner steel skeleton of a skyscraper the steel support beams and girders will have to be stiff so that they don't fall apart or the building doesn't shake due to wind or other natural forces.But in my research I've found that steel (mild steel to be more exact) is ductile and malleable, meaning it can be shaped fairly easily. However, how can steel ALSO be stiff - the definition of stiffness is the tendency to withstand bending and stretching - so my question is. How can this material be BOTH ductile/malleable, AND stiff? and why? :)Thank you in advance if anyone takes the time to answer this, would be appreciated - I'll give you 10 points straight away if the answers conclusive

- To say that steel can be bent and shaped fairly easily isn't quite true. It takes multiple tons of force to do so, requiring some very heavy machinery. I think you're confusing a couple of concepts. For example the idea of elastic modulus, versus rigidity Rigidity is the ability of a structure to resist a load. That depends not only on the elastic modulus, but on the size and design of the structure or object. You can build fairly rigid structures out of wood. For example roller coasters. Even though wood has a much lower elastic modulus than steel, meaning that it takes much less force to bend and deform a given sample of wood.

- Q: what is the densest type of steel ? what is its density ?what is its tensile strength .

- Agree okorder . If you are really looking for higher density, go to copper or tungsten.

- Q: Can steel coils be stamped?

- Yes, steel coils can be stamped. Stamping is a common process used to shape and form steel coils into various shapes and sizes for different industrial applications.

- Q: I also heard Stainless holds up better againts rust, blue steel needs more care.

- Stainless steel requires less maintenance, but I've got a K-38 Combat Masterpiece from 1974. Back then SW used the real blueing process, and the blue steel looks like its a foot deep. Probably the best looking gun in the accumulation. Still new in the box, never fired. Its my Vietnam tribute gun, same one I carried as a Security Policeman in the Air Force from 1969-1971.

Send your message to us

Hot Dipped Galvanized Steel Coil for Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords