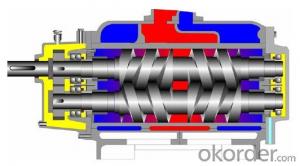

Horizontal Heavy Oil Twin Screw Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Working Features

Wide application, delivery all kinds of fluid media, even non-fluid ones

Bilateral rotation and delivery

Stable capacity and pressure, no pulse

Capacity is proportional to speed, so the pump can be used as dosing pump

Low operated noise, no-leakage and no temperature rise

Long life, low cost of operation maintenance

Delivery Media

Different viscous liquids, especially for the liquids with high viscosity which are difficult to be pumped. (up to 106 mm2/s)

Different dense liquids and dewatered dry medium

Liquids with solid particles (up to 70%), fibers (up to 350mm) and suspending media

Sensitive liquids that cannot be churned, sheared and compressed

Corrosive liquids (pH=0-14)

Fluid at high or low temperature (-10 – 150 C)

Application Fields

Environmental Engineering

Paper Making Industry

Oil Industry

Electrolyte Treatment

Mine Industry

Food Industry

The Material of Components Depends on Medium Features

Pump body (suction chamber, discharge casing and others) which connects with media:

cast iron, carbon steel, different stainless steel or flow surface plated with anti-corrosive materials are available;

Rotor: strong anti-abrasive alloy steel, different stainless steels and anti-corrosive alloy steel are available;

Stator: different rubber and other elastic materials are available;

Axial seal components: packing or mechanical seal according to your requirements.

- Q: You'd better point out the details.... There are 2 best ways of experience and formulaCan you say a simple point, such as multi-stage pump, when the pump is higher than the motor, 30 wire is the next mouth how to do?

- Alignment methods and requirements:1, check two feeler dial gauge or flange coupling the parallelism, usually with clearance between the both ends of the side instead of difference, in the circumferential direction every 900 measure, the maximum and minimum gap gap difference (Ab) less than or equal to 0.3 mm.2, the coupling flanges outside the park up and down, left and right four position to check whether they are in the same line, C less than or equal to 0.1 mm.When looking for a positive C, it will affect (a - b), finding the right (a - b) will affect the C, to balance each other. It's easier for an unskilled comrade to find C (a - b) first, and then find a positive one. Through the adjustment of the motor at the foot of the gasket thickness (Ab) and meet the requirements of C.Check the inlet and outlet piping before alignment. Make sure the weight of the inlet and outlet pipe does not exert force or torque on the pump. When looking for, should also pay attention to eliminate the pump rotor movement, so as to avoid the end gap error. If checked after the pump is working, it should be carried out under cold condition.It is important to draw attention to the fact that the pump set of the complete set of factory is only rough looking (checked with a ruler) when it is shipped. It may cause displacement when it is transported.

- Q: What are the causes of pump shock?

- 3. the water pump set screws loose, adjust the concentric, fastening the foot4. pump into foreign body, open cover overhaul5. the flow is too large or too small, adjust the equipment to control the water output

- Q: Is the diaphragm pump and the drain pump one?

- Therefore, the need to play a liquid discharge pump, if the medium is corrosive liquid, high viscosity, volatile, flammable, highly toxic liquid, you can choose diaphragm pump. Conversely, the general liquid, there is no special requirements, you can use the general centrifugal pump to reduce costs.

- Q: Is the vacuum pump air compressor?

- A vacuum pump is a device or device that uses a mechanical, physical, chemical, or physical chemical method to pump a vacuum from a container to be evacuated. Generally speaking, a vacuum pump is a device that uses various methods to improve, produce, and maintain a vacuum in a confined space.

- Q: Why can the centrifugal pump hold down the pressure?

- The centrifugal pump can hold pressure because of the suction pipe in the pump at the entrance of a non-return valve (valve).

- Q: Roots pump and dry pumpRecently involved in the work of the vacuum pump, don't understand this, is a ads602 vacuum pump, composed of roots pump and dry pump, is pre pumped to the 500mtorr equipment, the main pumping vacuum continues to 10mtorr, where the roots pump and dry pumps must be used? What role they play respectively. The so-called dry pump? Is refers to one kind of the pump, the pump is many dry pump? Also do not understand how the work of automatic switching system for pre pumping, the main pump, pump work alone did not connect system ah (of course there are even a butterfly) teach?

- Here the roots pump and dry pump must be used, because the roots pump is not used alone, and must be a stage vacuum pump (pre vacuum pump can be dry pump, water ring vacuum pump and rotary vane vacuum pump can be, you here with dry pump series)

- Q: Is vane pump good or gear pump good?

- The main parts of a gear pump are gears that mesh with each other. The meshing driving gear and the driven gear are respectively arranged on two parallel rotating shafts. Because the gear teeth enter and exit the meshes, the volume of the teeth is changed, and the suction and discharge effect is formed.

- Q: What is a feed pump?

- Feeding the role of the pump is to make the injection pump inlet pressure, increase the injection pump inlet pipe flow rate, in order to ensure high pressure water injection pump has sufficient supply.

- Q: Filter backwash pump for what use, what is the principle of work ah?

- When the filter is in normal operation, the impurity will be trapped in the upstream of the filter (filter medium). As the accumulation of impurities, the filter media will be blocked, and the direct performance is that the circulation will decrease. Usually, when the flow drops to a set point (the industry is usually judged by the pressure drop),

- Q: What does "dual purpose" of water pump mean? Please expert advice

- In order to ensure safe and continuous operation, three pumps usually need two units and run one standby.Precautions for using pumps1, if there is any small water pump failure, remember not to work. If the pump shaft packing end wear should be added in time, if you continue to use the water pump will leak. The direct effect of this is the increased energy consumption of the motor, which will damage the impeller.

Send your message to us

Horizontal Heavy Oil Twin Screw Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords