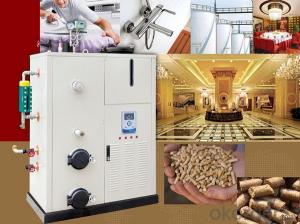

Horizontal Biomass Hot Water Hrsg Boiler

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Horizontal biomass hot water hrsg boiler

Specifications

1.Horizontal biomass hot water hrsg boiler

2.30000 Kcal

3.Biomass Pellet Fuel

4.Can be customized

Introduction

Reasonable boiler structure and special combustion method make automatic biomass gasification water boiler solved the deflagration and coking phenomenon from the source. Reasonable boiler structure and special combustion method make automatic biomass gasification water boiler solved the deflagration and coking phenomenon from the source.

Key Features

Control system: microcomputer control system, temperature setting, cycle control and fault alarm function, simple and easy to use.

High automation: we use advanced rotary screw to drive automatic feed device to feed the fuel automatically, only need to fill the storage hopper one time to satisfy 1-2 days need.

Convenient: boiler overall structure is compact, small size, no need to set up a tall chimney, easy installation, low failure rate.

Application Range

It can be widely used in garment manufacturing, food processing industries, hotel services, petrochemicals, schools, hospitals and enterprises, especially for the users in those areas have high requirements on environmental protection and energy saving.

Specification

| Project | Unit | GS0.035 | GS0.08 | GS0.18 | GS0.23 | GS0.7 |

| Rated heating value | Kcal | 3×104 | 7×104 | 15×104 | 20×104 | 60×104 |

| Rated working pressure | MPa | 0 | ||||

| Rated supply and return water temperature | °C | 85/60 | ||||

| Thermal efficiency | % | ≥90 | ||||

| Water yield | L | ≥600 | ≥1500 | ≥3300 | ≥4000 | ≥12000 |

| Reference heating area | m2 | 200~300 | 500~700 | 1000~1500 | 1500~2000 | 4000~5000 |

| Hot and cold water caliber | mm | 50 | 50 | 65 | 65 | 100 |

| Induced draft fan | KW | 0.08 | 0.55 | 0.75 | 0.75 | 3 |

| Blower | KW | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Heater band | KW | 4 | 4 | 4 | 4 | 4 |

| Feeder-conveyer | KW | 0.25 | 0.25 | 0.25 | 0.25 | 0.4 |

| Chimney exit diameter | mm | dia140 | dia140 | dia140 | dia140 | dia250 |

| Length | mm | 1300 | 2170 | 2620 | 1550 | 2700 |

| Width | mm | 450 | 550 | 600 | 1300 | 1860 |

| Height | mm | 1260 | 1370 | 1600 | 1650 | 2380 |

| Hauled weight | Kg | 380 | 430 | 510 | 780 | 1860 |

| Fuel consumption rate | Kg/h | 8 | 19 | 42 | 56 | 168 |

| Material storage apacity | Kg | 100 | 100 | 200 | 300 | 500 |

Note:

1.The data is for reference only, technical specifications may be subject to change without prior notice.

2. Our products can be customized. If any other parameters are needed, please contact me.

FAQ

Q:What's my consideration when i choose a gas stove?

A: -The style and size of your kitchen.

-The food or cooking style you prefer.

Q:Can i be a distributor of CNBM?

A: Of course you can.

Q:What are the benefits of being your gas stove distributor?

A: - Marketing protection.

- Priority of launching new design.

- Point to point technical supports and after sales services.

Q: How can i become a distributor of CNBM stoves?

A: Contact us immediately for further details by sending us an inquiry.

- Q:Is there a specific flow chart?

- Should have a greater impact on the positive reaction. Therefore, the acid catalysis is not selected for alkaline catalysis. Of course, you can also use the acid catalytic reaction, which will be free fatty acid reaction after the end of the use of alkaline catalysis, but this will make the operation process is more complex. At the end of the reaction, the reaction product of oil as raw material, if the oil pretreatment is relatively complete, that is, less impurities, only the reaction products were washed, dried. As a result of the production of bio diesel oil, and for the acidification of oil as raw materials, the reaction products, due to the acidification of the oil itself with a large number of impurities (such as non saponification, pigment, etc.)

- Q:How much is the initial investment of small biodiesel plant

- Biodiesel (Biodiesel) refining automatic vegetable oil, commonly used in tractors, trucks, ships, etc.. It refers to oil crops such as soybean, rapeseed, cotton, palm, wild oil plants and engineered microalgae and other aquatic plants oil and animal fat, food waste oil as renewable diesel can replace fossil diesel fuel made from raw oil by transesterification or thermochemical process. Biodiesel is a kind of biomass energy, which is similar to petroleum diesel in physical properties, but different in chemical composition.

- Q:Comprehensive utilization of biogas in rural areas

- Biogas lamp for greenhouse vegetables, carbon dioxide fertilization, and increase sunshine: biogas generally contains 25% to 35% of carbon dioxide and methane from 50% to 70%. Methane combustion can produce a large amount of carbon dioxide, and release a lot of heat. In general, the combustion of 1 cubic meters of methane can produce about 0.975 cubic meters of carbon dioxide. According to the principle of photosynthesis, growing vegetables in plastic greenhouses in the burning time, a certain amount of methane, carbon dioxide concentration and temperature being increased, which can effectively promote the yield of vegetables. The application of vegetable plant carbon dioxide strong growth, higher chlorophyll content, leaf color dark green glossy, early flowering, flower, flower and fruit abscission, and leaf shoots up strong resistance enhancement.Seedling raising in greenhouse is a technical measure to solve the problem of early transplanting and promoting early and high yield of rice. At present, most of the greenhouse are using coal or firewood as heating fuel, therefore, the annual seedling consumes a large amount of coal or firewood, the high cost of seedling. The use of biogas as the fuel heating greenhouse seedling, rice seedling cultivation is a new technology of comprehensive utilization of biogas, simple equipment, convenient operation, low cost, easy to control, not bad, fast germination, seedling emergence uniformity, high rate, easy to popularize.

- Q:Biogas can be used in the Northeast

- However, in the medium temperature fermentation, the optimal temperature is about 35 degrees Celsius, at 40~45 DEG C, gas production will decline.

- Q:Methane gas why not fire

- Your biogas digester gas production is very good, very successful, there is no gas point because the new pool of methane gas production is low, do not worry, you can:

- Q:Why not directly use biodiesel, 2% to be mixed with diesel

- Lubrication of lubrication is better than diesel blended with diesel can also improve diesel oil pump core, reduce wear, we are always direct car not what problem, the driver does not have what difference reaction with petroleum diesel.

- Q:The pressure of the methane tank is generally controlled at a high level

- Three, 1 Kpa (kPa) equal to the atmospheric pressure of the water column of 10.2 cmFour, the general pool of the highest pressure is about 1 m water column atmospheric pressureFive, the pressure of the methane tank, in the depth of the water tank is closely related to the general depth of the water tank is about 0.7 - 1 metersSix, a standard atmospheric pressure equal to 10.336 meters of water column

- Q:Biodiesel can be used directly as fuel for diesel engines

- Otherwise it will cause some damage to the engine

- Q:Is there a subsidy for biodiesel

- There is a value-added tax that is incremental policy

- Q:Is it safe?Will explode? Leak? Is it safe to build at school?

- When people enter the methane tank to take precautionsPersonnel into the digester, put the lid and into and out of the mouth opened open for 1-2 days, and to eliminate the biogas pool, pool blast to remove the residual gas. No chicken and other small animal testing, if there is no abnormal phenomenon, under the guardianship of pool care workers can enter the pool, into the pool of personnel must fasten the safety belt. In the pool after the dizziness, the feeling of hair, should be rescued immediately outside the pool. No single operation. Into the pool operation, the explosion-proof flashlight can be used, do not use oil lamps, matches or lighters and other lighting.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Horizontal Biomass Hot Water Hrsg Boiler

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords