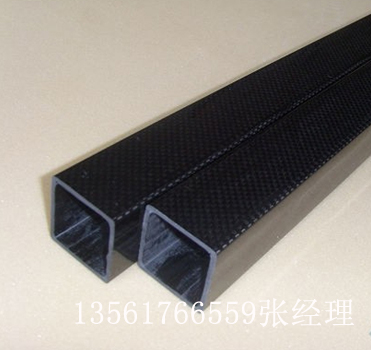

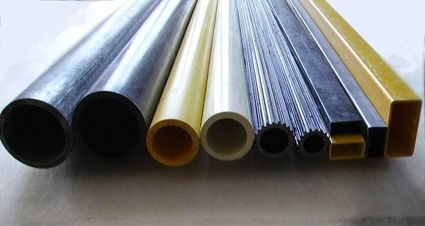

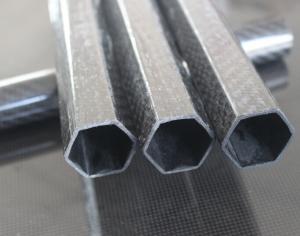

High Strength and Light Weight Carbon Fiber Tube

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description for Carbon Fiber Tube

Our composite tubing, and in particularly our carbon fibre tubes, have significant advantages over most materials in terms of mechanical properties. The table opposite shows comparisons with other common materials.

Property | CF Fabric | CF Uni-Directional | Steel | Aluminium |

Density (g/cc) | 1.60 | 1.60 | 8.0 | 2.7 |

Youngs Modulus 0°(GPa) | 70 | 135 | 207 | 72 |

Youngs Modulus 90°(GPa) | 70 | 10 | 207 | 72 |

Ult. tensile Strength 0°(MPa) | 600 | 1500 | 370 | 240 |

Ult. comp Strength 0°(MPa) | 570 | 1200 | 370 | 240 |

Ult. tensile Strength 90°(MPa) | 600 | 50 | 370 | 240 |

Ult. comp Strength 90°(MPa) | 570 | 250 | 370 | 240 |

As can be seen, carbon fibre has excellent strength and low density. If these two factors are considered together, therefore looking at ‘specific strength’, then the benefits of carbon fibre look even more impressive. This is highlighted in the graph opposite.

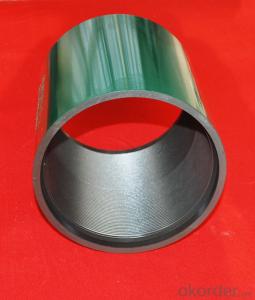

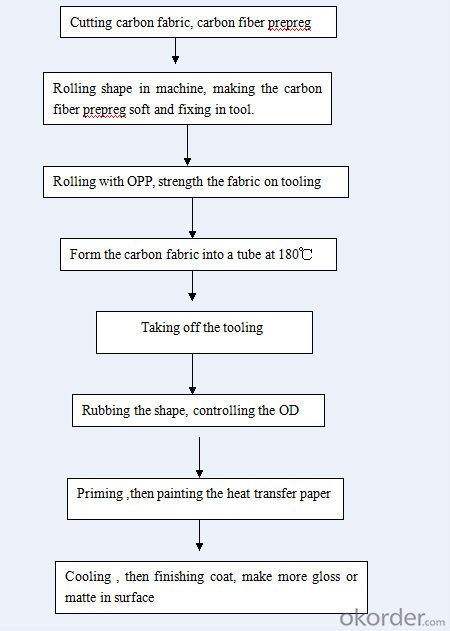

2.Production process

When the laminate has been designed and verified by our engineers the individual patterns are fed to our 5 metre long CNC cutting table which cuts out each pattern precisely. The materials we use are cloths which already have the resin matrix impregnated in to them, known as pre-pregs.

Next, these prepreg layers are wrapped around the male tooling (mandrels) which determine the Inside Diameter (ID) of the tube. These patterns are wrapped in an exact sequence on our machine driven rolling table to ensure consistency and accuracy of the lay-up.

The tubes are then subjected to a high temperature curing cycle under pressure in our electronically controlled ovens and finally removed from the tooling using a hydraulically powered puller mechanism.

Once complete, the raw blank is then ready to be machined and finished in line with the design specification.

The process of carbon fiber tube

3. Features for Carbon Fiber Tube

With over 60 years of collective marine experience we have a significant insight to this industry. This, coupled with our vast knowledge of composites, is invaluable given the diverse nature of composite marine applications.

We produce tubing for all types of marine applications, from small dinghy tiller extensions, paddle shafts, and spars up to one-off tubing for large yacht masts.

The flexibility of our manufacturing process is one of our distinctive qualities in this area:

Able to make tapered tubing which is ideally suited for mast applications.

We can make oval tubing often sought after for masts or booms requiring differential properties in different axes.

Tubes are made with epoxy resin systems which have virtually zero water absorption making them more suitable for marine based use than lower quality tubing made with vinylester or polyester resin systems.

We have in-house paint facilities and are able to finish tubes with UV stable paint systems, protecting the tubing against inevitable long exposure to the elements.

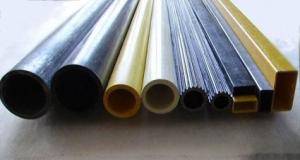

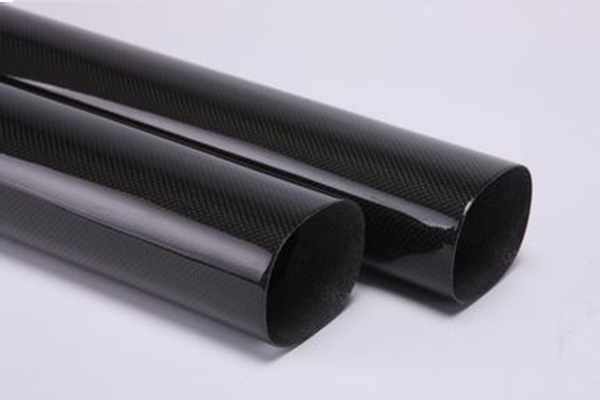

4. Photos for Carbon Fiber Tube :

- Q: had to ask this question w/ IE, b/c Firfox locks up everytime on the ask part of Y!A.

- turn it off or you,ll die

- Q: The pipe line of the hydraulic pressure pipe is formally installed

- The cleaned pipe shall be installed and filled as soon as possible(1) connect all the pipes in line by the print mark;(2) the fourth chapter according to the method of fastening all pipe joints, pay attention to remove the O-ring into the original;(3) all piping shall be firm and not loose;(4) all the oil pipes can be connected to the distributor, the oil outlet and the lubrication point until they are filled with grease

- Q: Does the alarm go off on a saturn L100 when you open it with a key? i lost the remote to my car and i don't want to try it because im not sure how to turn the alarm off

- In your position, I'd find a low place (such as the first floor ceiling, or in the basement if possible) where the existing pipe is clear and cut it off square. Before doing so, get a flash light and mirror if needed and determine where the pipe is supported. With those cast pipes being as heavy and brittle as they are, it's important to keep keep them supported securely. When possible, I like to use a circular saw or 4 angle grinder (cut off wheel) to do the cutting. They cause less vibration than many alternatives. If you need to use a sawzall, use a fine toothed metal cutting blade. Consider fernco fittings or others of their type to join the new PVC to the existing cast. You can get them from Home Depot, Lowes, Ace, etc. If you use silicone to seal up the new fittings (shouldn't be needed) be sure that everything is darned good and dry first.

- Q: Hi there..I'm a gap year student going off for volunteer work in Luang Prabang, Laos in November. Since it is hard to find many details on the internet, I thought I'd try here :)I would just like to know the basic conditions and things to be aware of, especially regarding safety in travelling alone (I'm an 18 year old girl and I look like I'm 12 :S ) Is it ok to visit the shops and walk around by myself? Also, are there any concerns about clothing, as in are there restrictions on what is appropriate.Since the organisation I'm volunteering for, pay for my meals and accomodation, I was wondering what would be a reasonable amount to have as spending money. As in how much would I need per month, for getting around, buying souvenirs, extra food, visiting attractions, etc.Thanks everyone!

- Yes I have, I haven't found anything worth mentioning though but I always get the strangest feeling that there is something out there waiting to be found.

- Q: The hydraulic pipe fittings how to distinguish the British, American, metric!

- Metric threads are represented by pitch, and American and English threads are expressed in thread per inch;Metric thread is 60 degrees equilateral tooth type, thread is isosceles 55 degree tooth type, thread is isosceles 60 degree tooth type;

- Q: I wonder if somebody could tell me how CO2 working as a fire extinguisher, regarding that it is full of oxygen?Or, is it possible that there are is some type of substance that is not possible to extinct with CO2.Is it possible that CO2 make an opposite reaction and enlarge fire?

- Pipe dope (joint compound) does not normally dry out. After it is applied it remains soft and pliable, although with time it will form a crusted surface. The pipe dope is used to form a better seal between the threads of the pipe and the fittings. As the pipe and the fittings change temperatures, the materials will expand and contract. If the pipe dope dried out it would crack and begin to leak over time. By remaining pliable it maintains the seal and prevents leakage.

- Q: If you could think of one it would be much appreciatedthanks

- crimp much holes tighter, all-ways brass fittings , cinch or crimp on a plastic fitting may cause failure or cracks.not seen until a leak or flooding. I've and done the freeze test on pex with a 2'ft. piece with plugs in the ends, both cinch crimp, plastic fitting brass/ both pex piping swell, but the plastic gave out. use pipe insulation with 3/4 wall like armor flex. check r value on insulation for your area.

- Q: You guys, I don't understand.Products from various countries have many interfaces, and I have just joined a supplier of plastic protection products for sale. In too many countries are not very clear, their standard, if can give me some information, such as the European standard + corresponding English, I think there will be a great help to me, not very understanding can also answer, hope can learn about. Thank you。

- For thread purposes, you are recommended to study the metric, American and American thread standards manual

- Q: A week ago someone broke into my 1991 Nissan Sentra and tried to steal it. They damaged the ignition cylinder and it is CRAZY expensive to replace for this car. Even if replacement was an option, I cannot remove the lock cylinder because they ruined it and I can't put the key in (at all) to turn it to the accessory position (needed to remove the cylinder, I've done a lot of research). My primary problem is: How can I remove the cylinder without the key? I've seen many topics about drilling it out, but I need specifics. OR How can I bypass the Steering wheel lock? (We bypassed the ignition cylinder, but the damn wheel was locked) It's been over a week now and the car has almost gotten tickets for sitting in the same area by the city. If you have a solution, please email me. I understand this is a strange situation, but the car must be moved ASAP into our driveway before we get fines, and have the money to pay a locksmith. THANKS!!

- Umm Mr. Fragile I would say Micheal Vick. He's always hurt The Chosen one is Peyton or Brady The Goofball is Elite Manning Idk the rest

- Q: if you answer i don't need the typical gith clothes are not cheap i know that i just need an answer for my question.all my clothes are so worned (sorry for my english) and i have nothing to wear i am not in the best possition to buy clothes right now but i need something to wear and because in my country we don't have many cheap goth stores i buy online.in the moment i need something cheap. please do NOT answer if you can't answer my question thank you and sorry for being rudep.s something like that

- To properly cut and re-thread steel pipe you need a pipe cutter, pipe threader, and pipe deburrernone of which are cheap. If you know how long a piece you need, have the supply house or home center cut and thread the piece(s) for you. I think Lowes does this for little or no extra cost. If you have a lot of threading to do, try renting the cutter, threader, and de-burrer, plus a pipe vise. [You will also need cutting oil for the threading process.] You then use couplings, not unions, to rejoin the pieces. [Unions are used to join two pipes when you cannot turn one of the pipes because it is already in place.] Use standard forged couplings, not the cheap smooth merchant couplings which often come with pipe lengths. Be sure to use high quality pipe dope to join the pipe/fittings. It comes in tape or brush on types, depending on your preference, the type of pipe, and what the pipe will carry [water, gas, etc.]

Send your message to us

High Strength and Light Weight Carbon Fiber Tube

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords