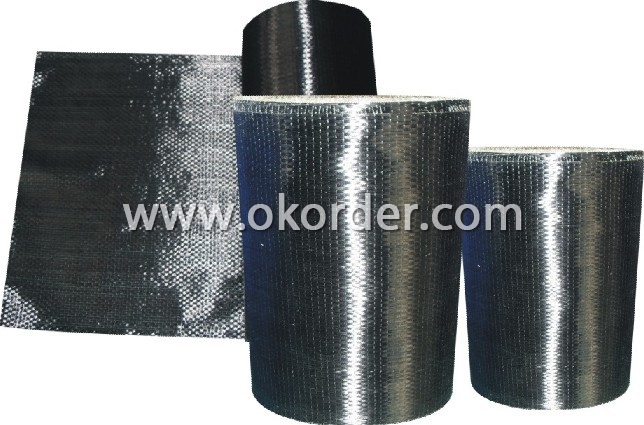

Carbon Fiber Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2Ton kg

- Supply Capability:

- 500Ton Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Carbon Fiber Tape:

Temperature: less than 550 degree C;

Width: 10mm to 150mm, on customers request;

Thickness: 1.5mm to 6.0mm, as your requirements.Carbon fiber tape is woven by carbon fiber, used as insulation materials and an excellent substitute for asbestos tape. High adhesive, resistant to abrasion and moisture, economical, high tensile strength, long storage.

Application of Carbon Fiber Tape:

Industrial thermal insulation, piping and electrical cable lining, shielding against heat radiation, high temperature oven door curtain, flange jointing with bolts, friction reinforcement materials, etc.

General Data of Carbon Fiber T400

Weaving Style: Unidirectional, Plain, Twill

Input Available: 3k, 6k, 12k Carbon fiber

Weight: 15 0 ~ 600g / m2

Roll length: To be specified

Storage of Carbon Fiber Tape

It is recommended that the carbon fiber fabric are stored in a cool and dry environment. Recommended temperature range of storage is between 10 ~ 30 degree and relative humidity between 50 ~ 75%.The carbon fiber fabric should remain in the packaging until just prior to use.

Packaging & Delivery of Carbon Fiber Tape

Product is manufactured in form of a roll wound on a paper tube and then packed in a plastic film and placed within a cardboard carton. Rolls can be loaded into a container directly or on pallets.

- Q: How does carbon contribute to the hardness of steel?

- The hardness of steel is enhanced by carbon through a process called carbonization. By introducing carbon atoms into the iron lattice of steel, interstitial solid solutions are formed, resulting in distortion of the lattice. This distortion hinders the easy sliding of iron atoms, thereby increasing resistance to deformation and enhancing the hardness of the steel. The strength and hardness of steel are further enhanced by increasing the carbon content, but only up to a certain limit. Nonetheless, excessive carbon can render the steel brittle, thus it is crucial to strike a balance to attain optimal hardness without compromising other properties of the steel.

- Q: What is the role of carbon in the formation of diamonds?

- The role of carbon in the formation of diamonds is essential, as diamonds are composed entirely of carbon atoms arranged in a crystal lattice structure. The extreme heat and pressure deep within the Earth's mantle cause carbon atoms to bond tightly together, forming the unique structure of a diamond. Without carbon, diamonds would not exist.

- Q: How does carbon pricing work?

- Carbon pricing is a market-based approach that puts a price on carbon emissions, either through a carbon tax or a cap-and-trade system. The aim is to create an economic incentive for businesses and individuals to reduce their greenhouse gas emissions. By putting a price on carbon, it encourages companies to invest in cleaner technologies, reduce their emissions, or purchase emissions allowances from other entities. This mechanism helps to address climate change by reducing carbon dioxide emissions and promoting the transition to a low-carbon economy.

- Q: What are the impacts of carbon emissions on the stability of coastal areas?

- Carbon emissions have significant impacts on the stability of coastal areas, posing various challenges to the environment and communities residing in these regions. One of the most prominent impacts is sea-level rise, caused by the melting of polar ice caps and thermal expansion of seawater due to rising global temperatures. As carbon dioxide and other greenhouse gases accumulate in the atmosphere, they trap heat, leading to the warming of the planet. This, in turn, causes glaciers and ice sheets to melt, contributing to the rising sea levels. Sea-level rise poses a direct threat to coastal areas, resulting in increased erosion, coastal flooding, and the loss of valuable land. As water levels rise, the shoreline retreats, eroding beaches and cliffs, and endangering coastal infrastructure and habitats. This erosion not only threatens the stability of coastal ecosystems but also puts human settlements at risk, leading to the displacement of communities and loss of property. Moreover, the increase in carbon emissions leads to ocean acidification, whereby the excess carbon dioxide is absorbed by the ocean, resulting in a decrease in its pH levels. Acidic waters have detrimental effects on marine life, including coral reefs, shellfish, and other marine organisms that rely on calcium carbonate for their shells and skeletons. As the acidity of the ocean increases, these organisms struggle to form and maintain their protective structures, leading to the degradation of coastal ecosystems and the loss of biodiversity. Another impact of carbon emissions on coastal areas is the intensification of extreme weather events, such as hurricanes and tropical storms. Warmer ocean temperatures provide more energy for these storms, making them more powerful and destructive. These events can cause extensive damage to coastal infrastructure, including buildings, roads, and utility systems. Furthermore, they can result in the loss of lives and livelihoods, exacerbating the vulnerability of coastal communities. In summary, carbon emissions have far-reaching impacts on the stability of coastal areas. Sea-level rise, ocean acidification, and intensified extreme weather events all contribute to the degradation of coastal ecosystems, loss of biodiversity, erosion, and coastal flooding. These impacts not only threaten the environment but also pose significant risks to human settlements, requiring urgent mitigation and adaptation measures to protect coastal areas and the communities that rely on them.

- Q: What is carbon steel, carbon manganese steel?

- Compared with other kinds of steel, carbon steel is the earliest, low cost, wide performance range and the largest amount. For nominal pressure PN is less than or equal to 32.0MPa, temperature of -30-425 water, steam, air, hydrogen, ammonia, nitrogen and petroleum products such as medium. Commonly used grades are WC1, WCB, ZG25 and high quality steel 20, 25, 30 and low-alloy structural steel 16Mn

- Q: What is carbon neutral manufacturing?

- Manufacturing goods while minimizing or offsetting carbon emissions is what carbon neutral manufacturing is all about. The goal is to reduce greenhouse gas emissions at every stage of the manufacturing process, from obtaining raw materials to disposing of finished products. Achieving this involves various measures, such as improving energy efficiency, utilizing renewable energy sources, implementing sustainable practices, and investing in carbon offset projects. To become carbon neutral, manufacturers typically start by conducting a comprehensive assessment of their carbon footprint. This involves identifying and quantifying all emissions generated in their operations, including both direct emissions from manufacturing processes and indirect emissions from energy sources. Once emissions are measured, manufacturers can devise strategies to decrease their carbon footprint. Common methods for achieving carbon neutrality in manufacturing include optimizing energy consumption through efficient equipment and technologies, adopting renewable energy sources like solar or wind power, and implementing waste reduction and recycling programs. Additionally, manufacturers can invest in carbon offset projects that aim to reduce or eliminate greenhouse gas emissions, such as reforestation or renewable energy initiatives. By implementing these measures and offsetting any remaining emissions, manufacturers can achieve carbon neutrality. This not only helps combat climate change by reducing overall carbon footprints but also demonstrates a commitment to sustainability and environmental responsibility. Carbon neutral manufacturing is an important step towards transitioning to a low-carbon economy and creating a more sustainable future.

- Q: How does carbon impact the prevalence of ocean acidification?

- Carbon impacts the prevalence of ocean acidification primarily through the process of carbon dioxide (CO2) absorption by seawater. Increased levels of atmospheric CO2, mainly caused by human activities such as burning fossil fuels and deforestation, lead to more CO2 being dissolved in the oceans. This excess CO2 reacts with seawater to form carbonic acid, which lowers the pH of the ocean and increases its acidity. This increased acidity has detrimental effects on marine life, particularly organisms with calcium carbonate shells or skeletons, as it hampers their ability to build and maintain their structures. Overall, the high levels of carbon in the atmosphere contribute to ocean acidification, which poses significant threats to marine ecosystems and biodiversity.

- Q: How does carbon impact ocean acidity?

- Carbon impacts ocean acidity through a process called ocean acidification. When carbon dioxide (CO2) from human activities is emitted into the atmosphere, a significant portion of it is absorbed by the ocean. Once in the ocean, CO2 reacts with water to form carbonic acid, which lowers the pH of seawater, making it more acidic. This increased acidity can have detrimental effects on marine life, particularly on shell-forming organisms like corals, mollusks, and some plankton, as it hampers their ability to build and maintain their calcium carbonate structures. Additionally, ocean acidification disrupts the delicate balance of marine ecosystems, affecting various species and ultimately impacting the entire food chain.

- Q: What is the role of carbon in photosynthesis?

- The role of carbon in photosynthesis is to serve as the building block for glucose, the main energy source for plants. Carbon dioxide (CO2) is captured during photosynthesis and converted into glucose through a series of chemical reactions. This process, known as carbon fixation, is essential for plants to produce food and release oxygen into the atmosphere.

- Q: How can Dungeon Fighter Online's superior furnace rock carbon be obtained?

- Bought in cash. You can go to the mall to have a look.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 20,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Carbon Fiber Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2Ton kg

- Supply Capability:

- 500Ton Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords